Method for the integration of a nitrogen liquefier and liquefaction of natural gas for the production of liquefied natural gas and liquid nitrogen

a technology of nitrogen liquefier and natural gas, which is applied in the direction of liquefaction, solidification, cold treatment separation, etc., can solve the problems of underutilization of nitrogen producing equipment, inability to operate or not operate at optimal conditions, and waste of potential refrigeration capacity, so as to achieve more efficient and flexible methods of producing lng, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102]While the invention will be described in connection with several embodiments, it will be understood that it is not intended to limit the invention to those embodiments. On the contrary, it is intended to cover all the alternatives, modifications and equivalence as may be included within the spirit and scope of the invention defined by the appended claims.

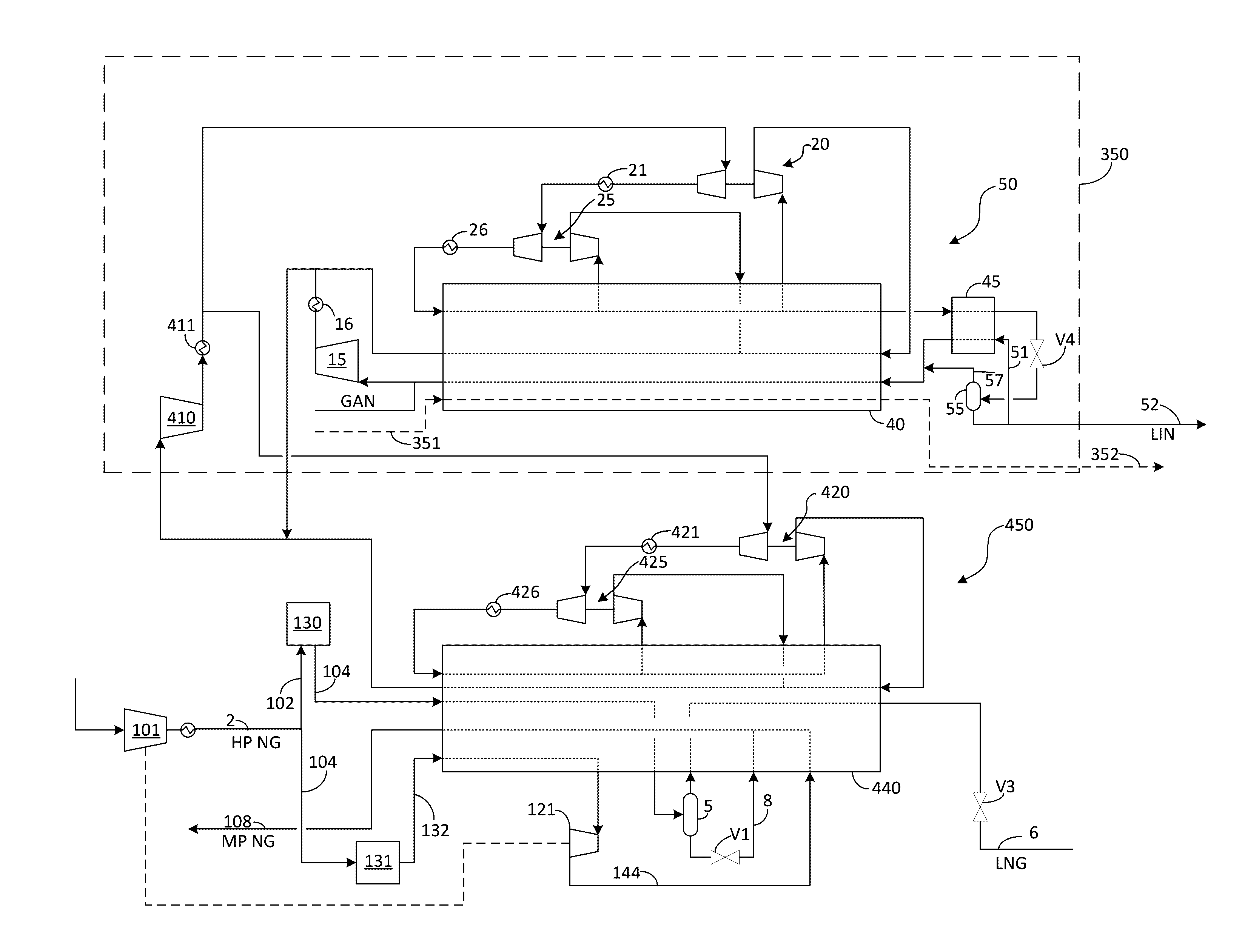

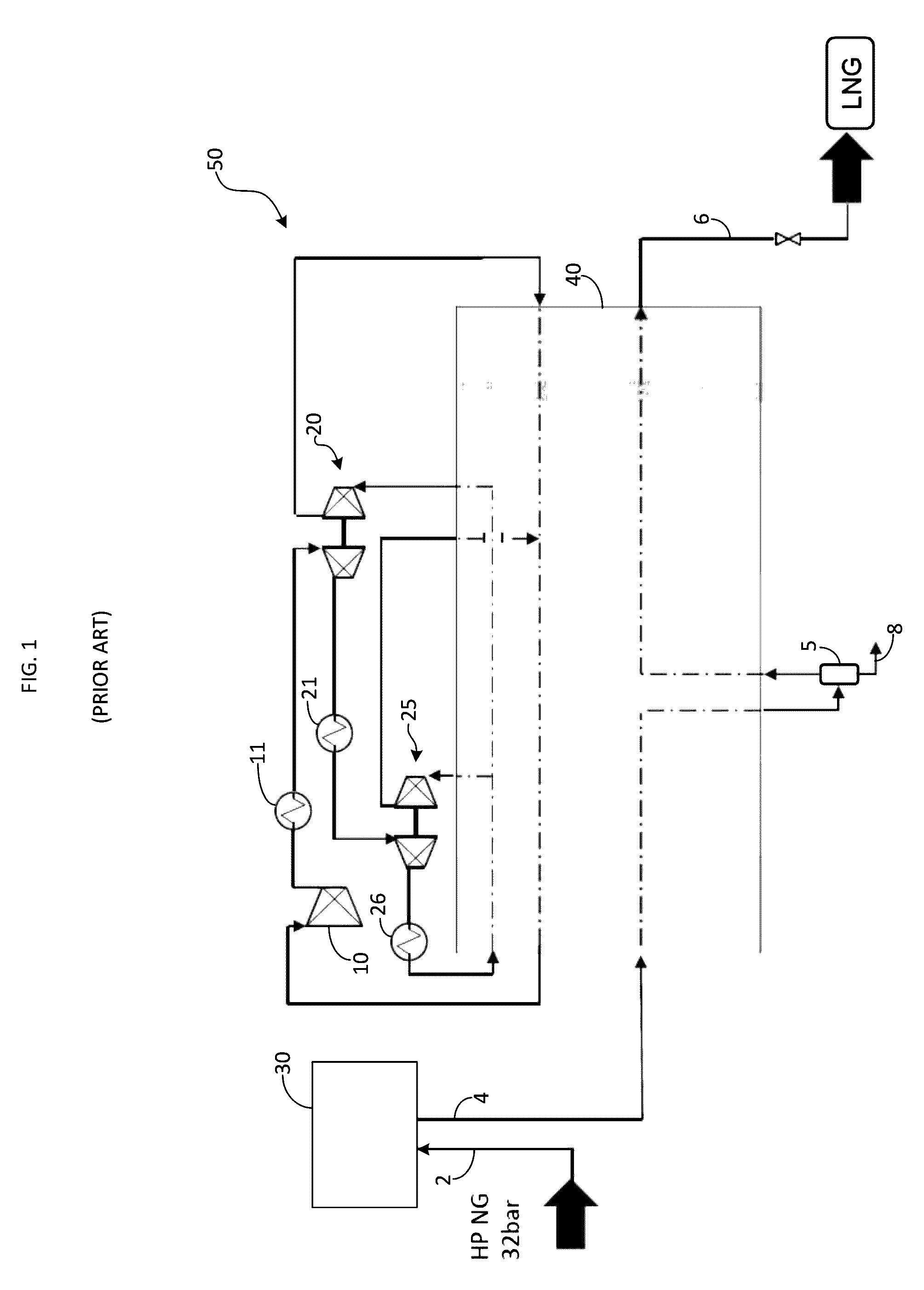

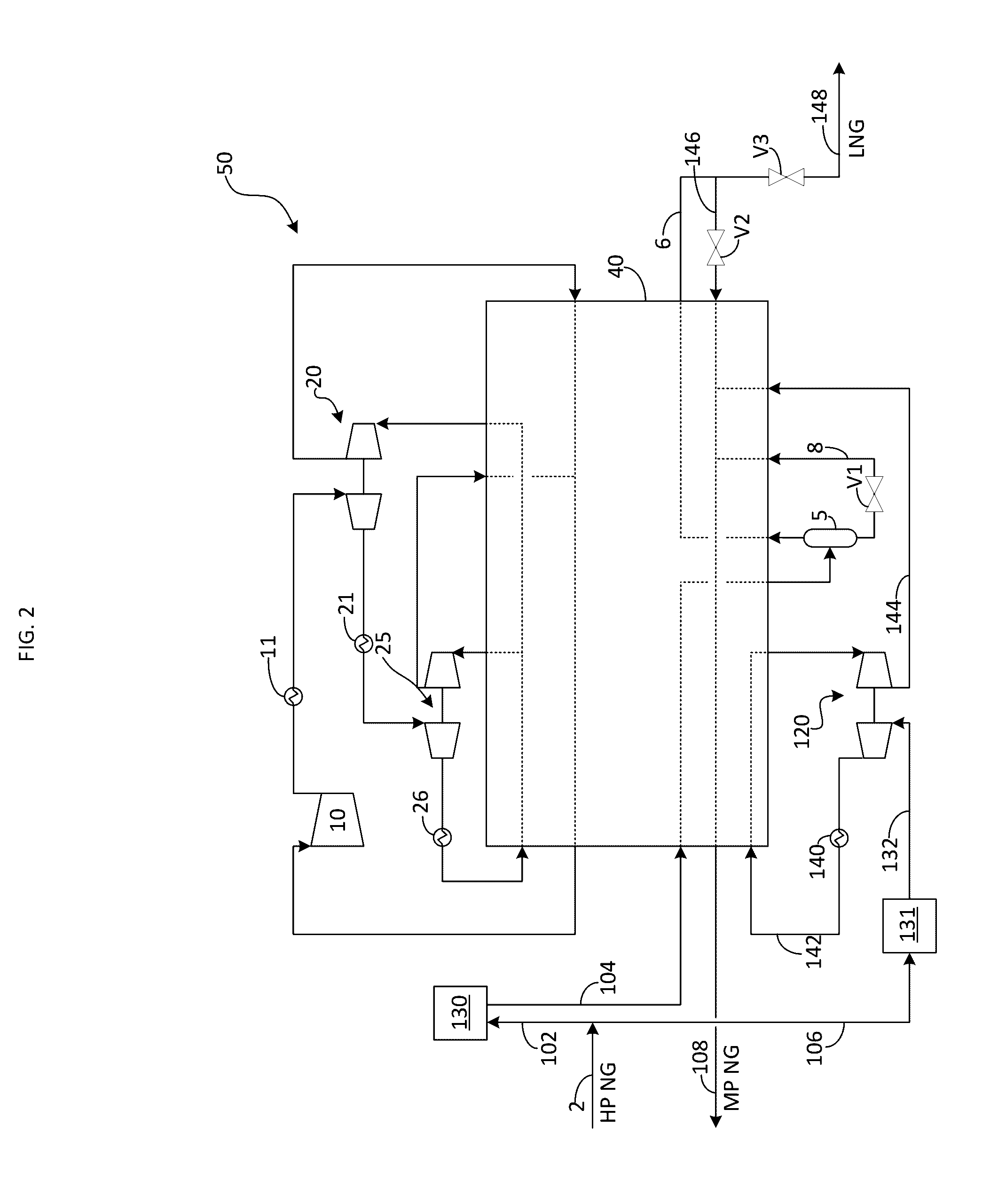

[0103]In one embodiment, the method can include integrating a natural gas letdown system with a nitrogen refrigeration cycle. In one embodiment, the nitrogen refrigeration cycle is a closed loop refrigeration cycle. In this embodiment, the natural gas letdown essentially provides “free” refrigeration energy since the natural gas would have been alternatively letdown across a valve (i.e., the resulting drop in temperature of the natural gas would have been absorbed by the surroundings and would not have been recovered in any meaningful way). With the addition of a natural gas turbine booster, LNG can be co-produced with a signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com