Apparatus for the production of liquefied natural gas

a technology of liquefied natural gas and apparatus, which is applied in the direction of liquefaction, solidification, cold treatment separation, etc., can solve the problems of complicated dispersion of methane gas, high cost and maintenance costs of such plants, and may not achieve the production of liquid from methane with high pressure alone, so as to achieve more efficient and flexible methods of production and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]While the invention will be described in connection with several embodiments, it will be understood that it is not intended to limit the invention to those embodiments. On the contrary, it is intended to cover all the alternatives, modifications and equivalence as may be included within the spirit and scope of the invention defined by the appended claims.

[0064]There is a demand for low cost localized nano-scale (e.g., <10 mtd) LNG production. Typical current systems on the market for nano-scale LNG production utilize forms of closed loop cycles with a refrigeration compressor that requires electrical consumption.

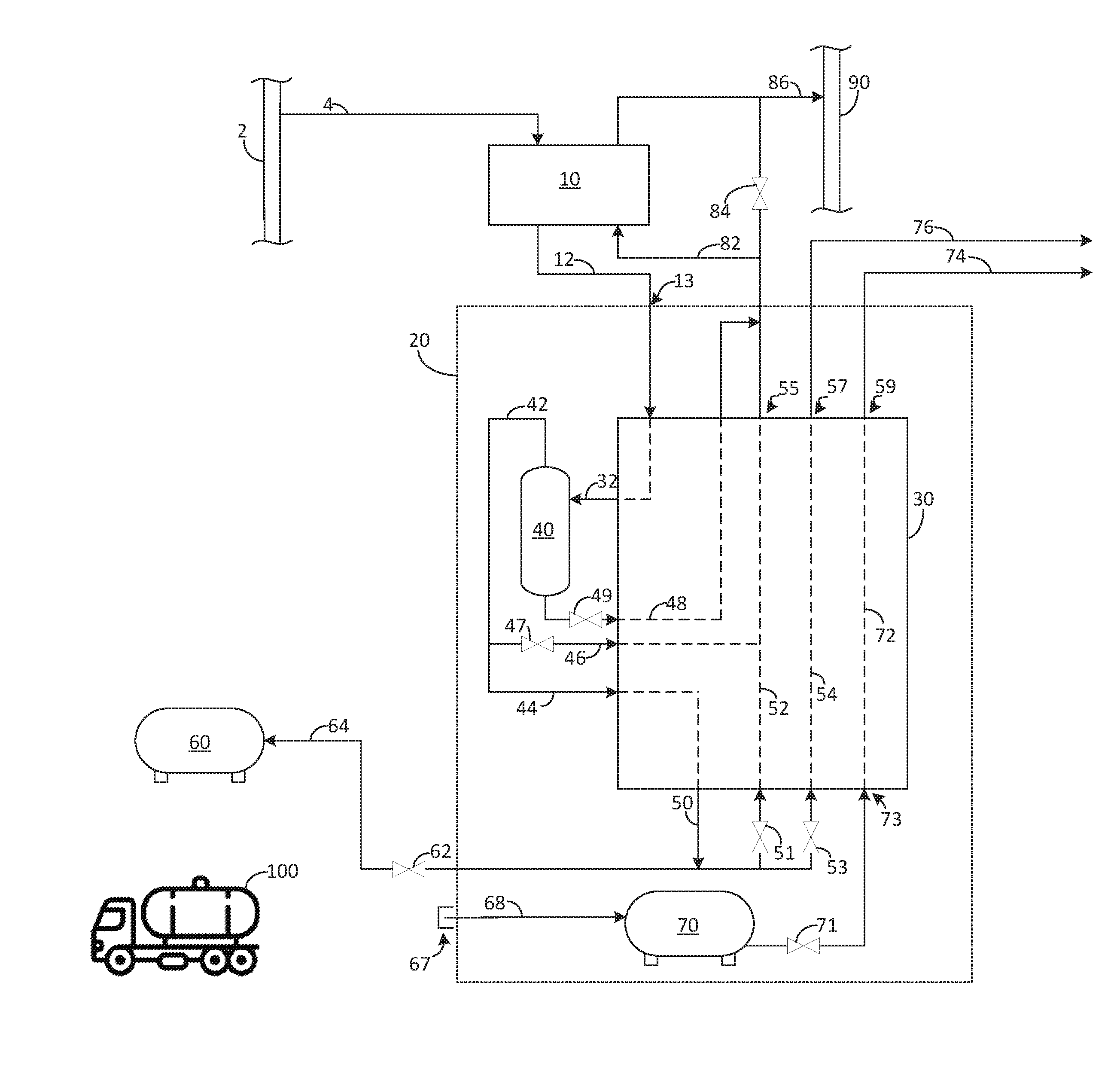

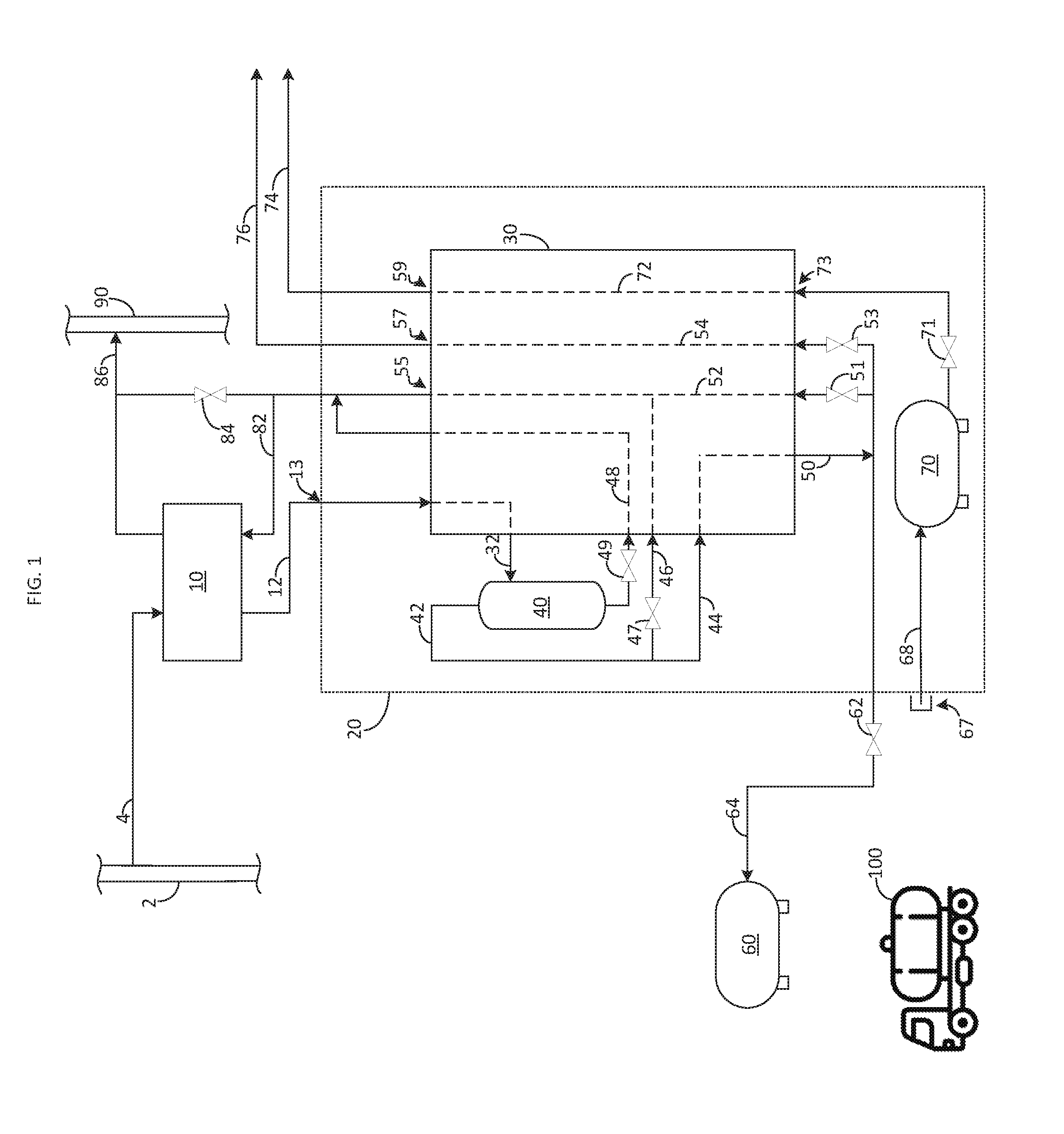

[0065]In one embodiment, the present invention proposes a solution for liquefaction of natural gas (LNG) which can be packaged (within size of truck trailer, barge, etc. . . . ) and preferably requires “zero energy” consumption and contains no rotating machinery equipment. This saves on setup of electrical equipment and operating maintenance.

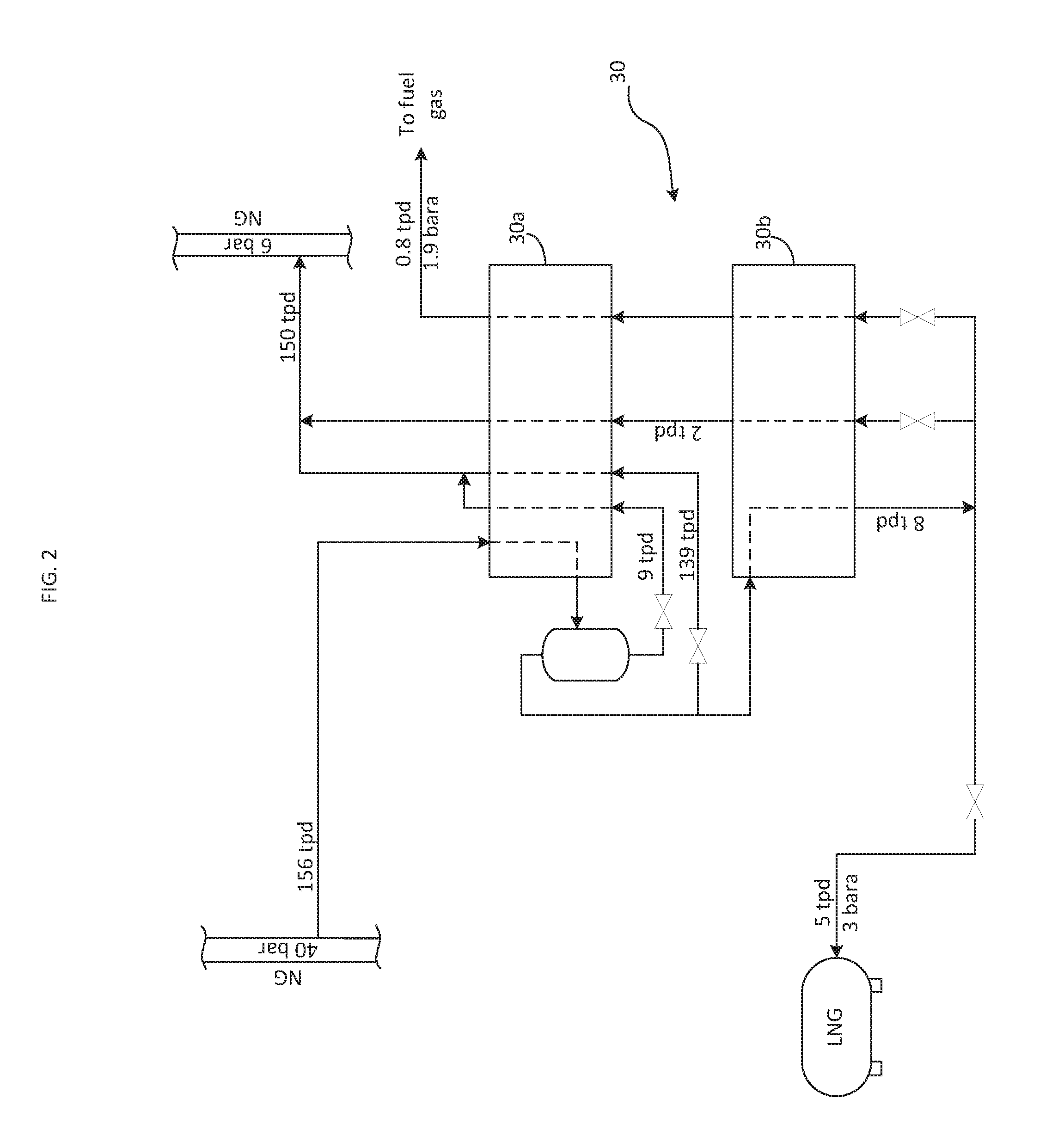

[0066]In one embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com