Port Connection for a Heat Exchanger

a heat exchanger and port connection technology, applied in indirect heat exchangers, laminated elements, lighting and heating apparatus, etc., can solve the problems of increasing the cost of installation, and increasing the cost of port connection, so as to reduce the cost and time of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

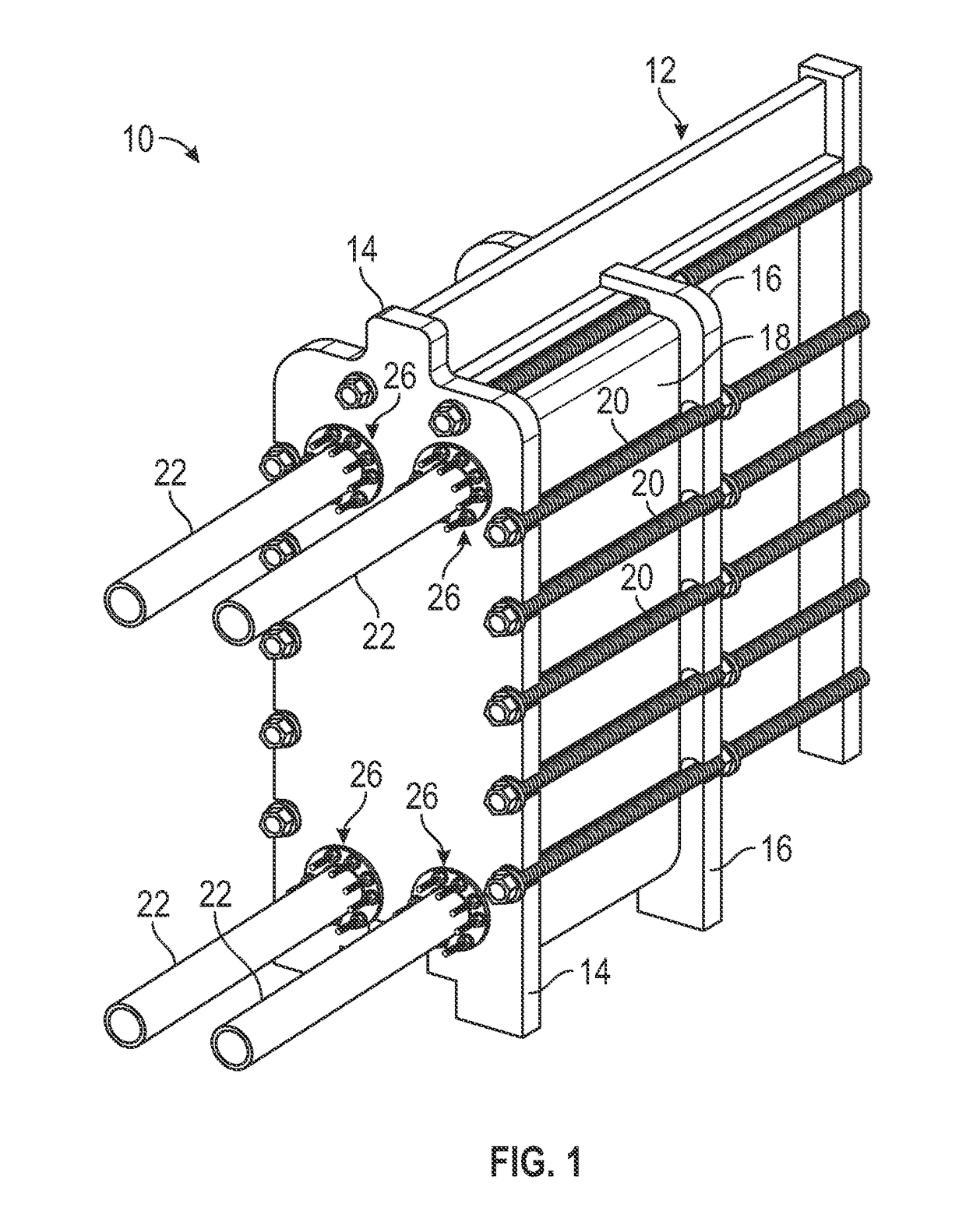

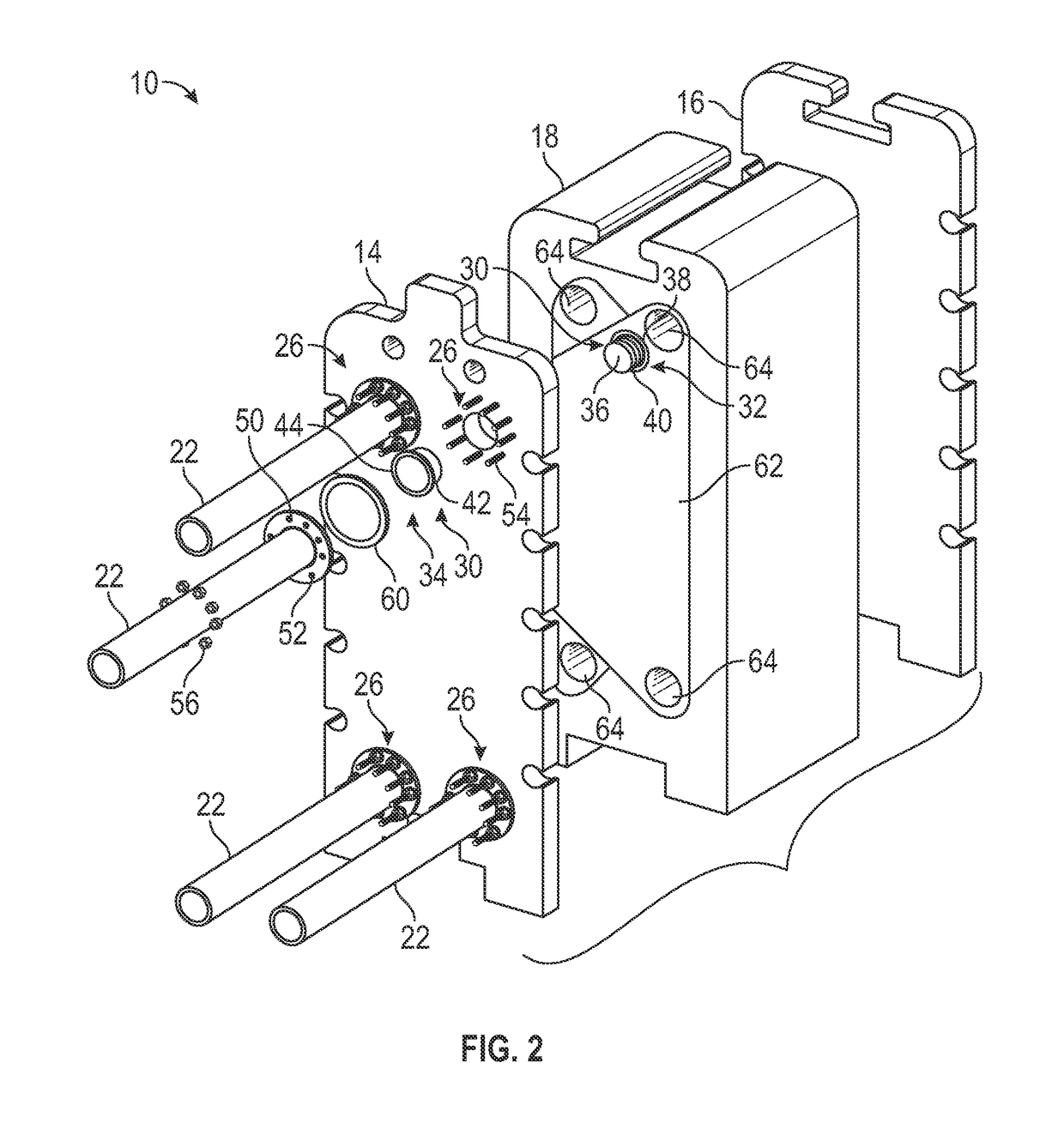

[0019]In general, embodiments of the invention pertain to a port connection for a heat exchanger that is easier to install and / or maintain than conventional port connections and / or offers cost savings over conventional port connections and a method of assembling the improved port connection in port of a pressure plate of the heat exchanger. In addition to ease of installation, improved maintenance, and reduced cost of the improved port connection described herein, tooling and machine costs are reduced by omitting welding and / or hydroforming associated with conventional port connection installation.

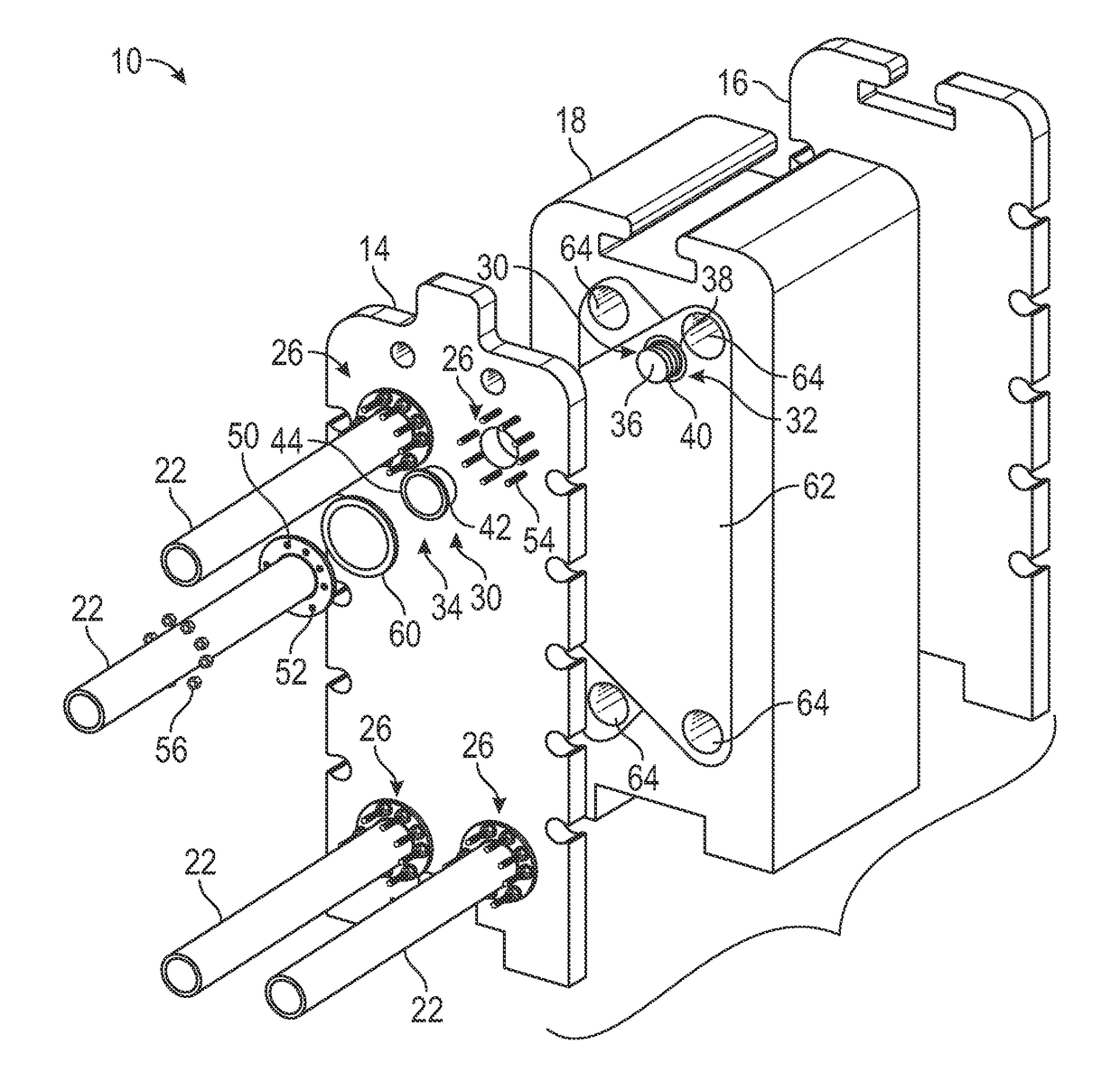

[0020]Referring now to the figures wherein like reference numerals indicate like elements, in FIG. 1 is a perspective view of a heat exchanger 10 suitable for use with embodiment of the invention. As shown in FIG. 1, the heat exchanger 10 includes a frame 12 having a pair of pressure plates 14 and 16, a plate pack 18, a plurality of tie bar assemblies 20 and a plurality of supply / output co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com