Polishing apparatus

a technology of polishing apparatus and polishing pad, which is applied in the direction of manufacturing tools, lapping machines, and abrasive surface conditioning devices. it can solve the problems of low operating rate of the cmp apparatus, the number of substrates polished does not necessarily reflect the accurate end point of the polishing pad life, and the polishing pad performance decreases. , the effect of accurately determined and decreased polishing performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

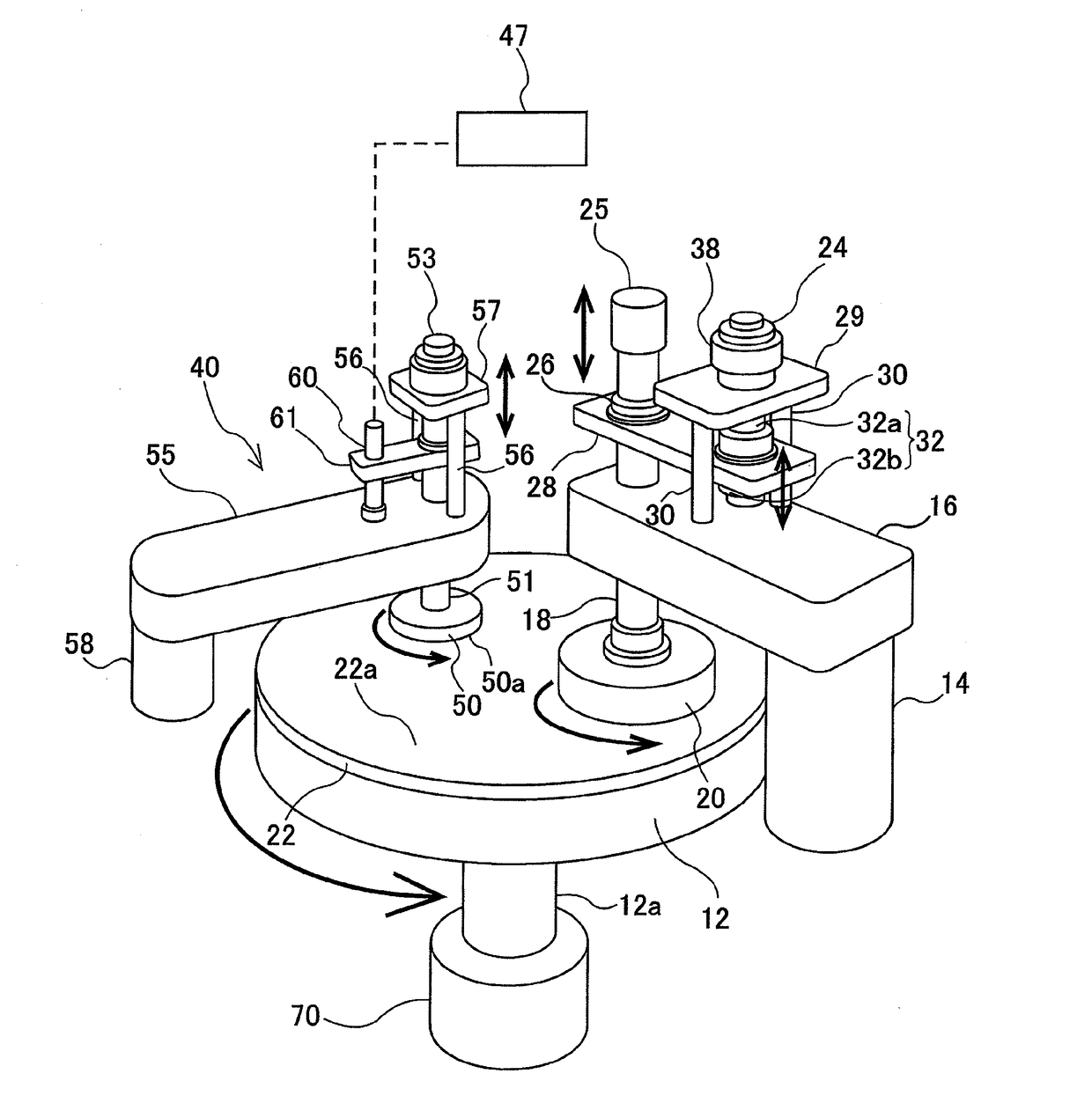

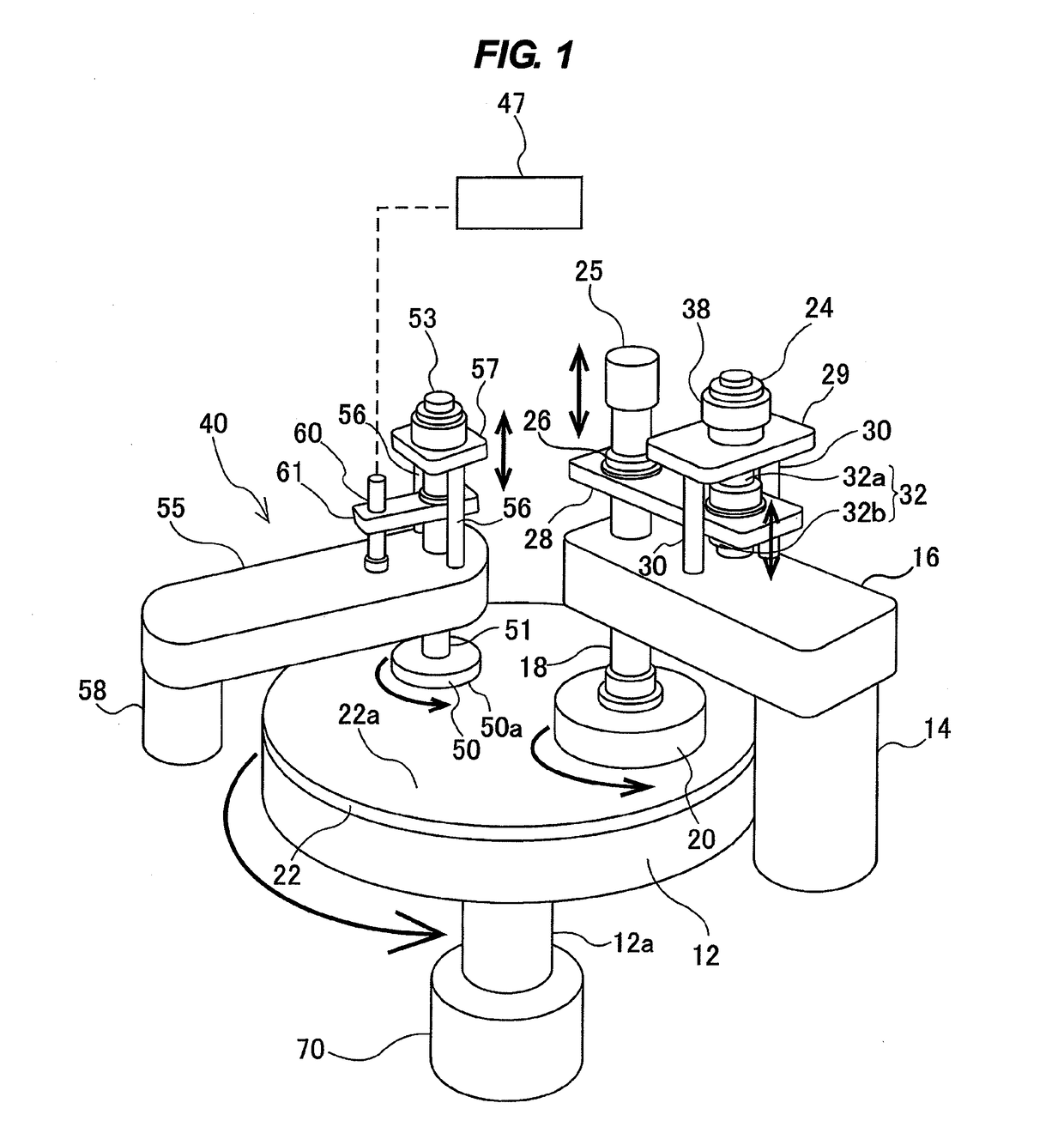

[0038]FIG. 1 is a schematic view of a polishing apparatus according to an embodiment of the present invention. As shown in FIG. 1, the polishing apparatus has a polishing table 12, a top ring swing arm 16 coupled to an upper end of a support shaft 14, a top ring shaft 18 supported by a free end of the top ring swing arm 16, a top ring 20 having approximately a disk shape and coupled to a lower end of the top ring shaft 18, and a diagnostic device 47 for processing various kinds of data. Although not shown, the diagnostic device 47 has a storage device for storing the data therein and an arithmetic processor for processing the data. Although not shown in FIG. 1, the top ring shaft 18 is coupled to a top ring rotating motor via a coupling mechanism, such as a timing belt, so that the top ring shaft 18 is rotated by the motor. This rotation of the top ring shaft 18 causes the top ring 20 to rotate about the top ring shaft 18 in a direction indicated by arrow.

[0039]The polishing table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com