Vacuum-generating pumping system and pumping method using this pumping system

a pumping system and vacuum-generating technology, applied in the field of vacuum technology, can solve the problems of system bulkiness, system reliability problems, and variable speed drive speed variation entail additional costs and bulkiness, and achieve the effects of reducing internal leakage, reducing pressure in the chamber, and improving the final vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

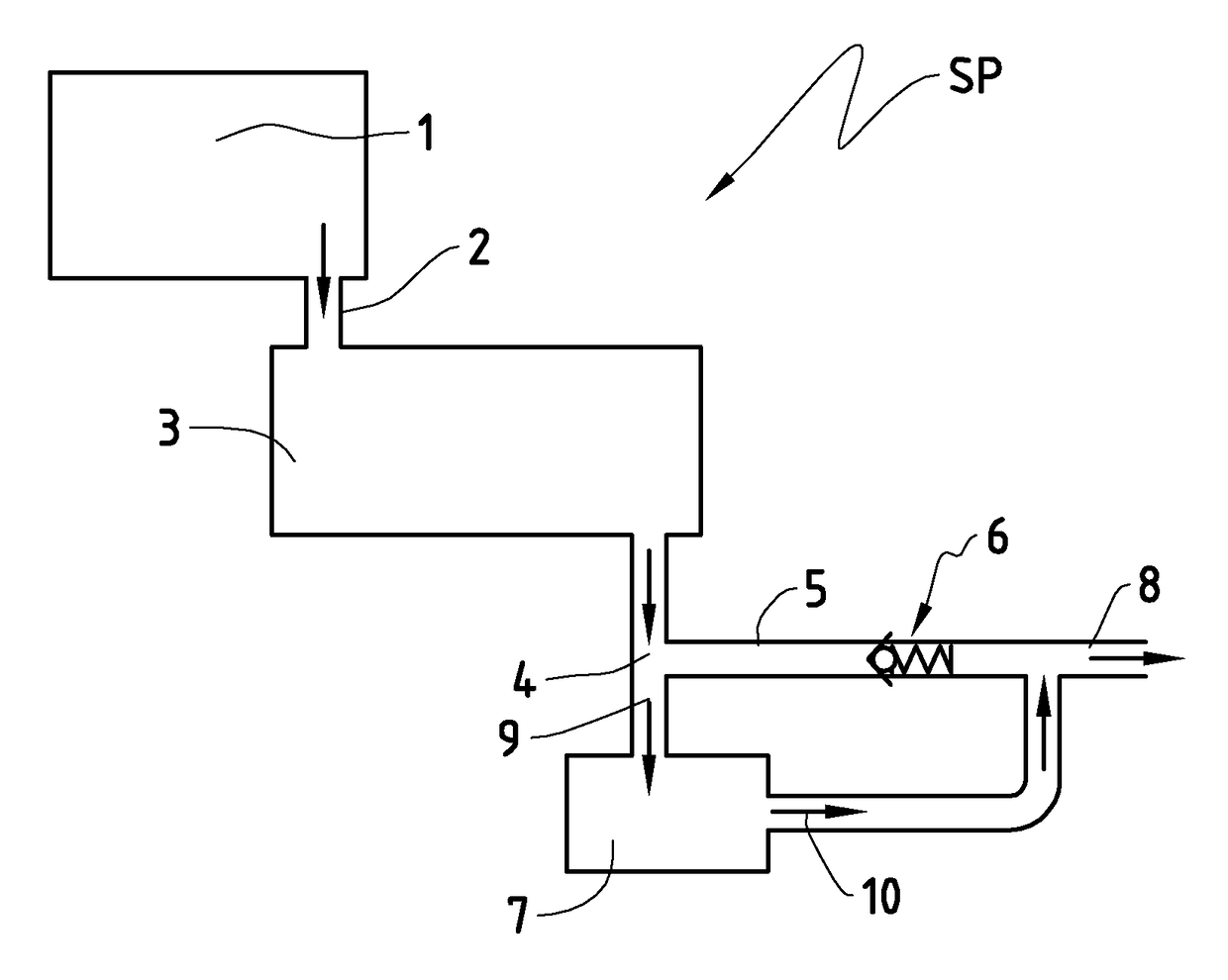

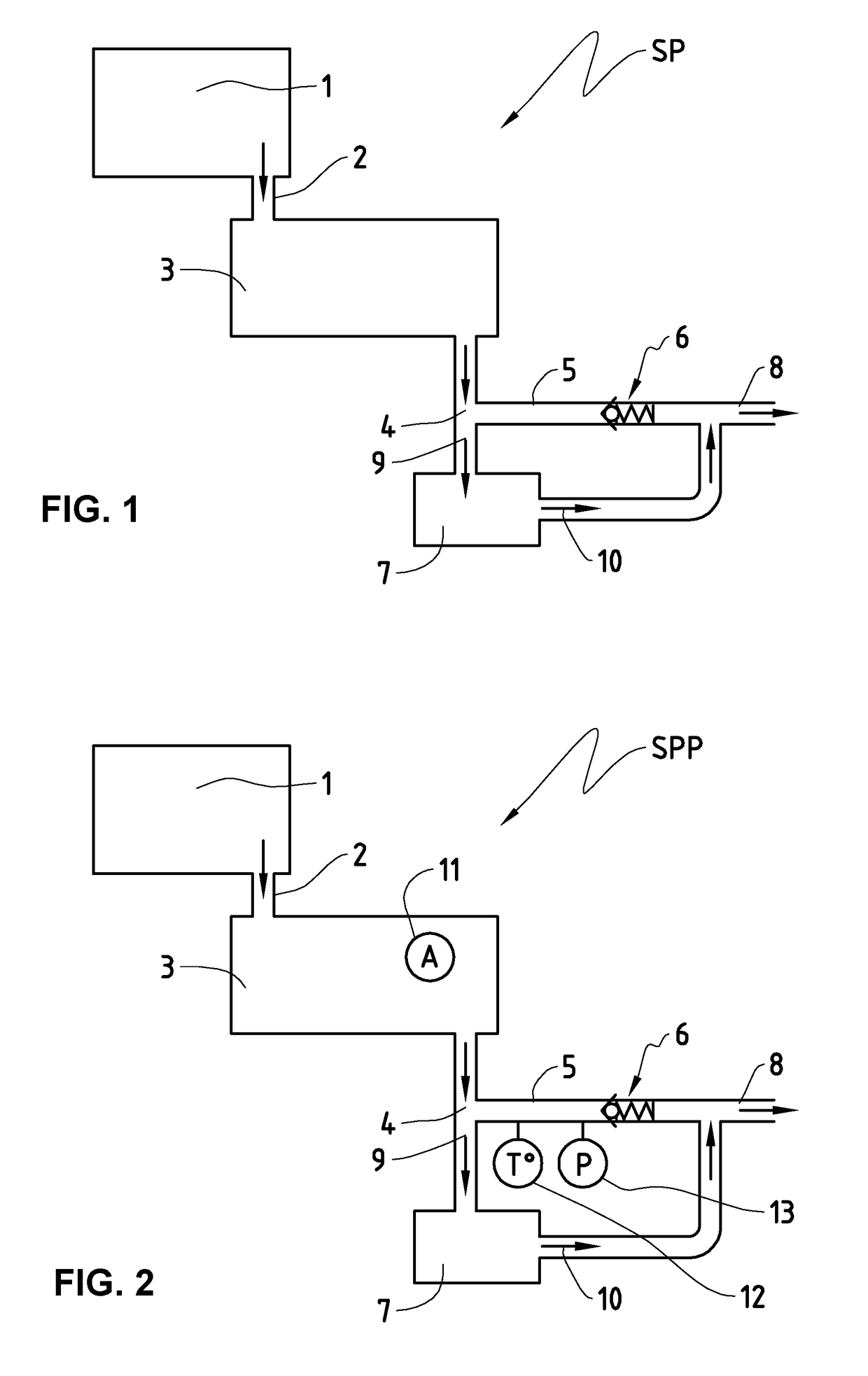

[0034]FIG. 1 represents a pumping system SP for generating a vacuum, which is suitable for implementing a pumping method according to the present invention.

[0035]This pumping system SP comprises a chamber 1, which is connected to the suction end 2 of a main vacuum pump constituted by a dry screw pump 3. The gas discharge outlet of the main dry screw vacuum pump 3 is connected to an evacuation conduit 5. A non-return discharge valve 6 is placed in the evacuation conduit 5, which, after this non-return valve, continues into the gas exit conduit 8. The non-return valve 6, when it is closed, permits the formation of a volume 4, contained between the gas discharge outlet of the main vacuum pump 3 and itself.

[0036]The pumping system SP also comprises the auxiliary vacuum pump 7, connected in parallel to the non-return valve 6. The suction end of the auxiliary vacuum pump is connected to the space 4 of the evacuation conduit 5 and its discharge end is connected to the conduit 8.

[0037]Alrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com