Form-fitting Corner Protector Member or Profile for Facing and Finishing Inside Corners and Edges

a corner protector and profile technology, applied in the field of corner protector members, can solve the problems of failure of surface treatments such as tile and tile grout and other sealants, affecting the appearance of the surface,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

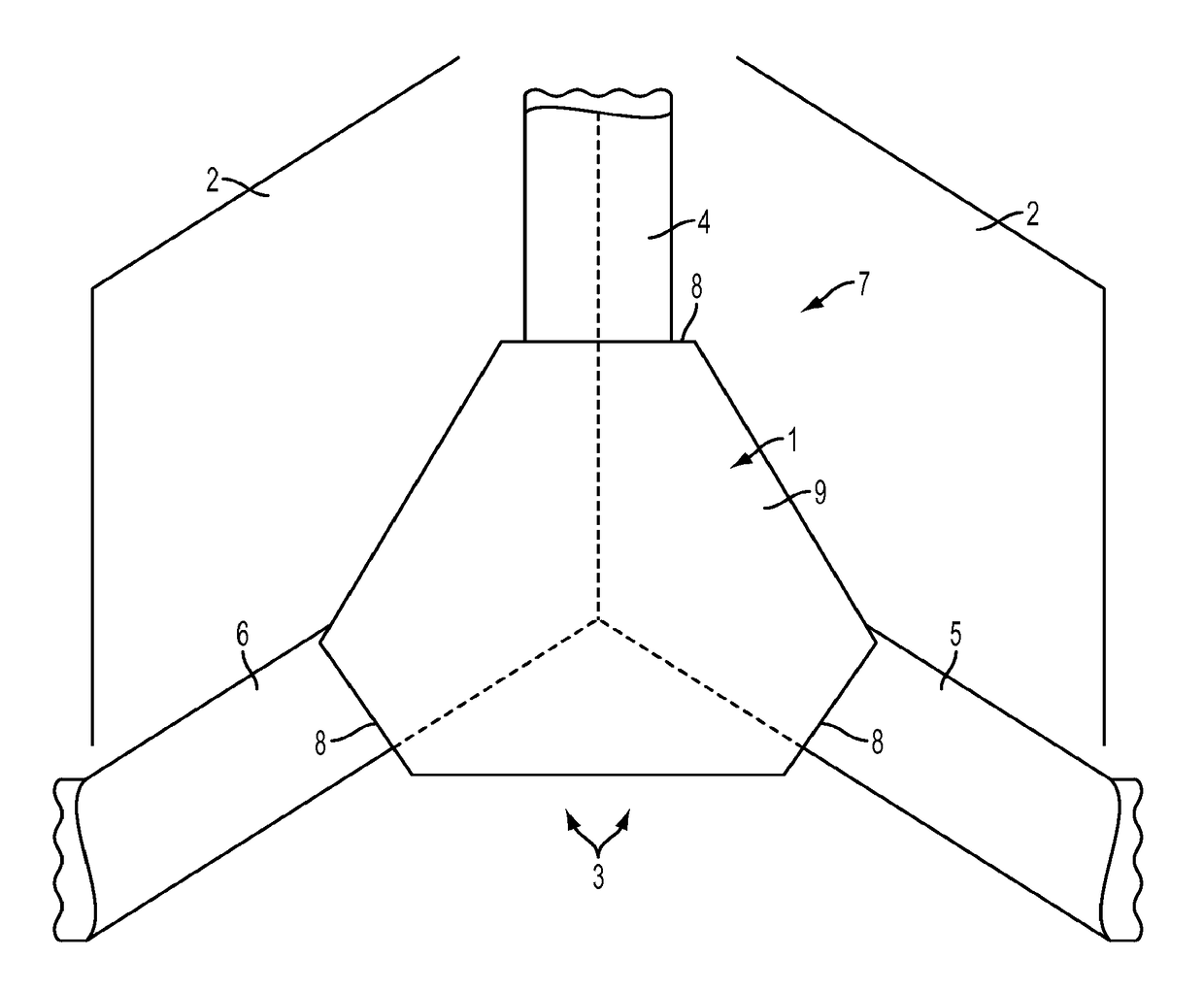

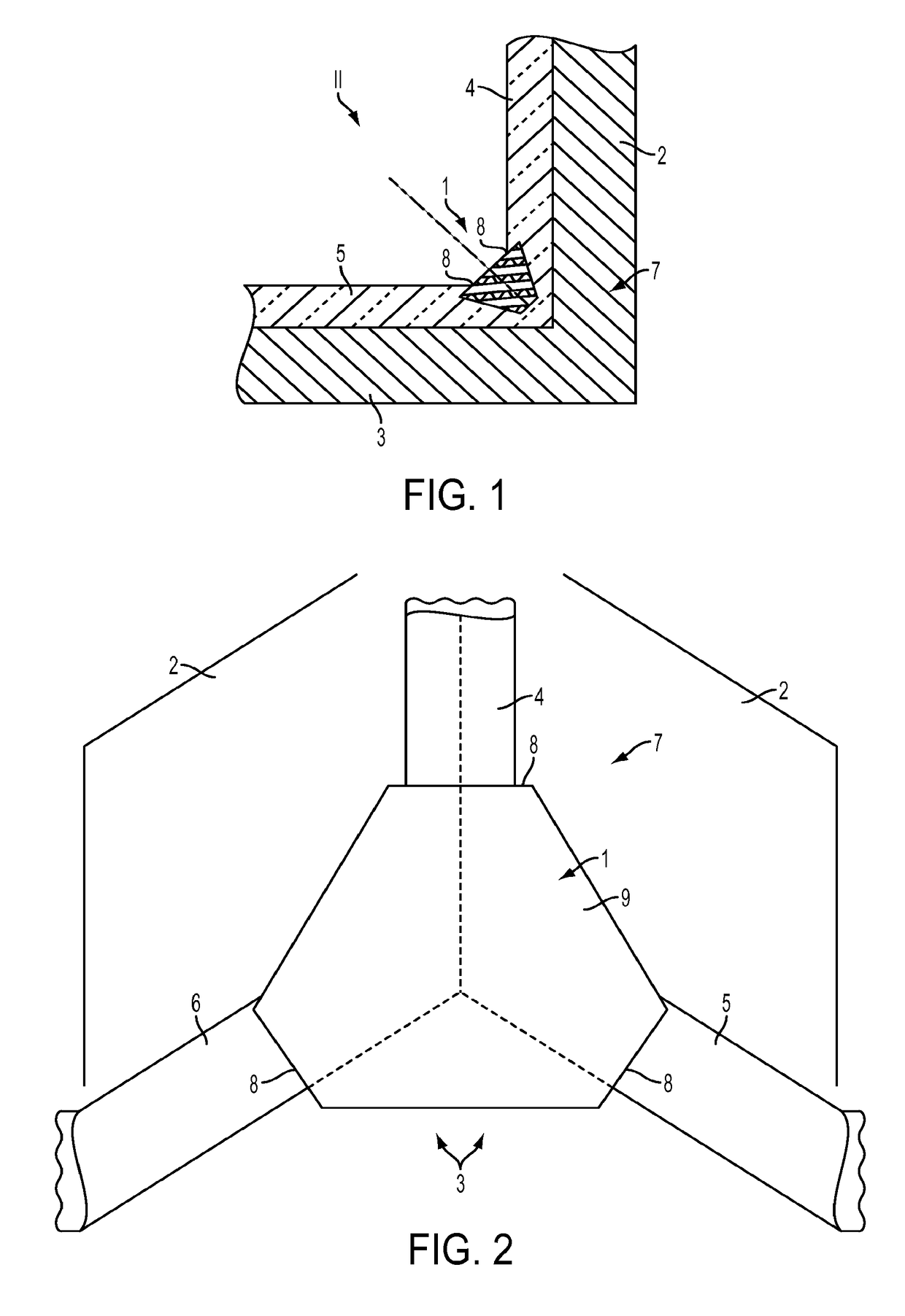

[0070]FIGS. 1 and 2 depict a first embodiment of the inventive corner protector member, which is depicted as completing and finishing an inside corner 7 of a room. As depicted, a vertical wall surface 2 meets a horizontal floor surface 3 at an angle of approximately ninety degrees, thus establishing the corner of a room as depicted in FIG. 2.

[0071]Depicted for purposes of illustration is the wall of a sanitary architectural installation, for example a bathroom, which features a vertical interstice, seam or joint 4 and two horizontal, angularly intersecting vertical walls, each of which feature a similar interstice, seam or joint 5, 6 and all of which converge at an inside corner 7, where the inventive corner protective member device is mounted or otherwise affixed to the interstices, seams or joints 4-6, and where the inventive corner protective member has been fitted by the application of pressure into as-yet uncured adhesive, caulk or sealant emplaced in or filling interstices, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com