Integrally Formed Fan Guard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The technical characteristics, contents, advantages and effects of the present invention will be apparent with the detailed description of a preferred embodiment accompanied with related drawings as follows.

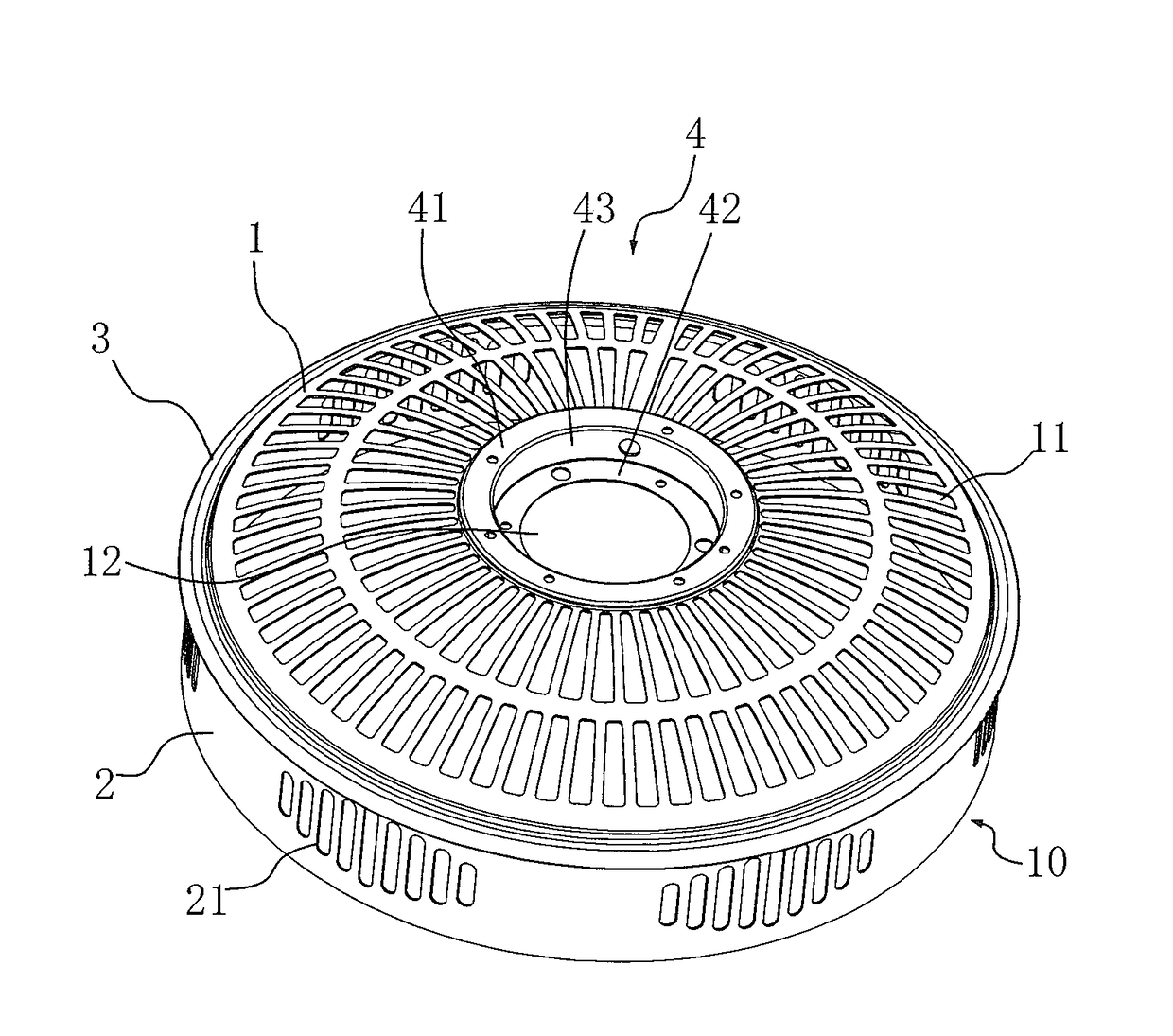

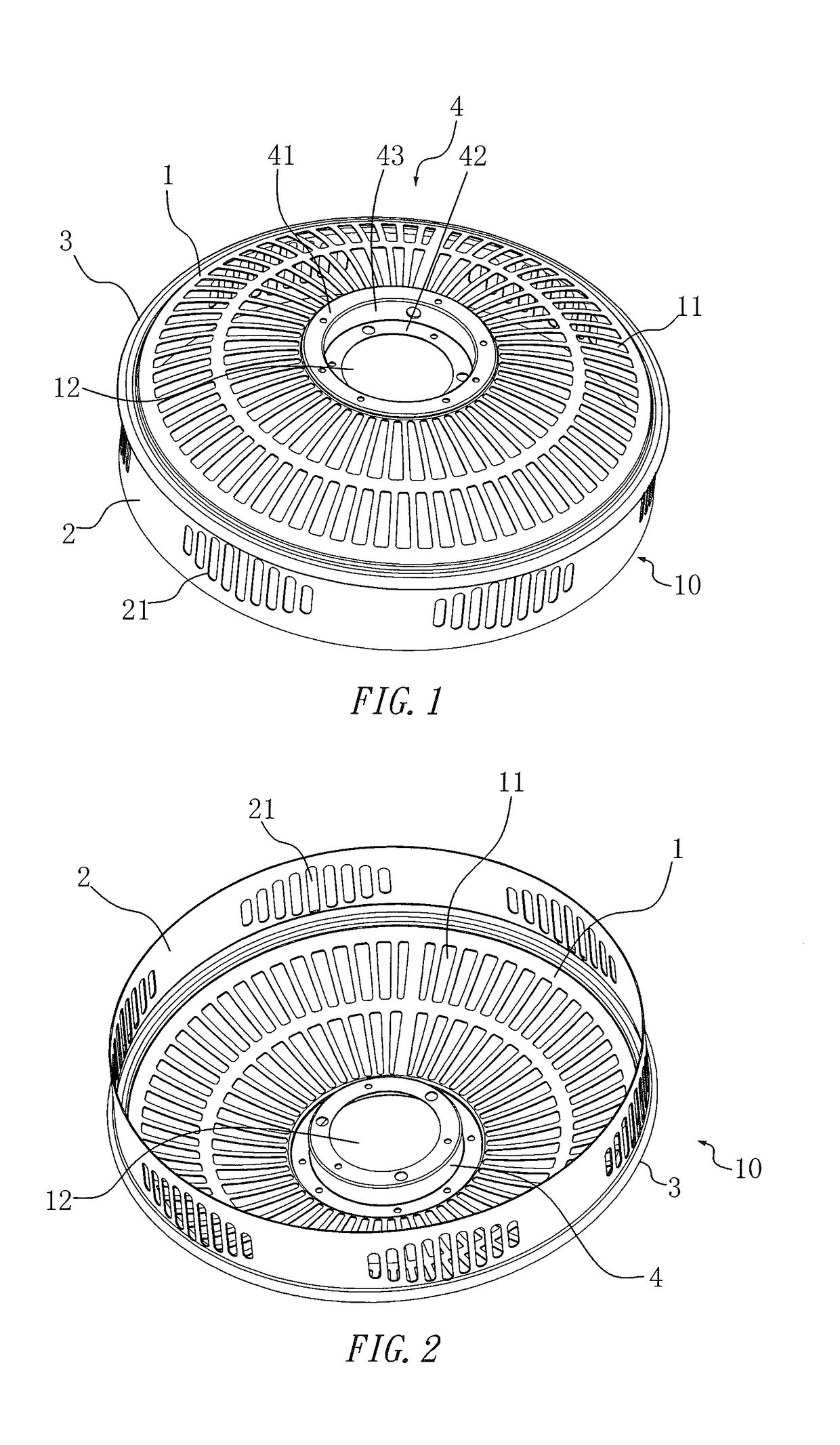

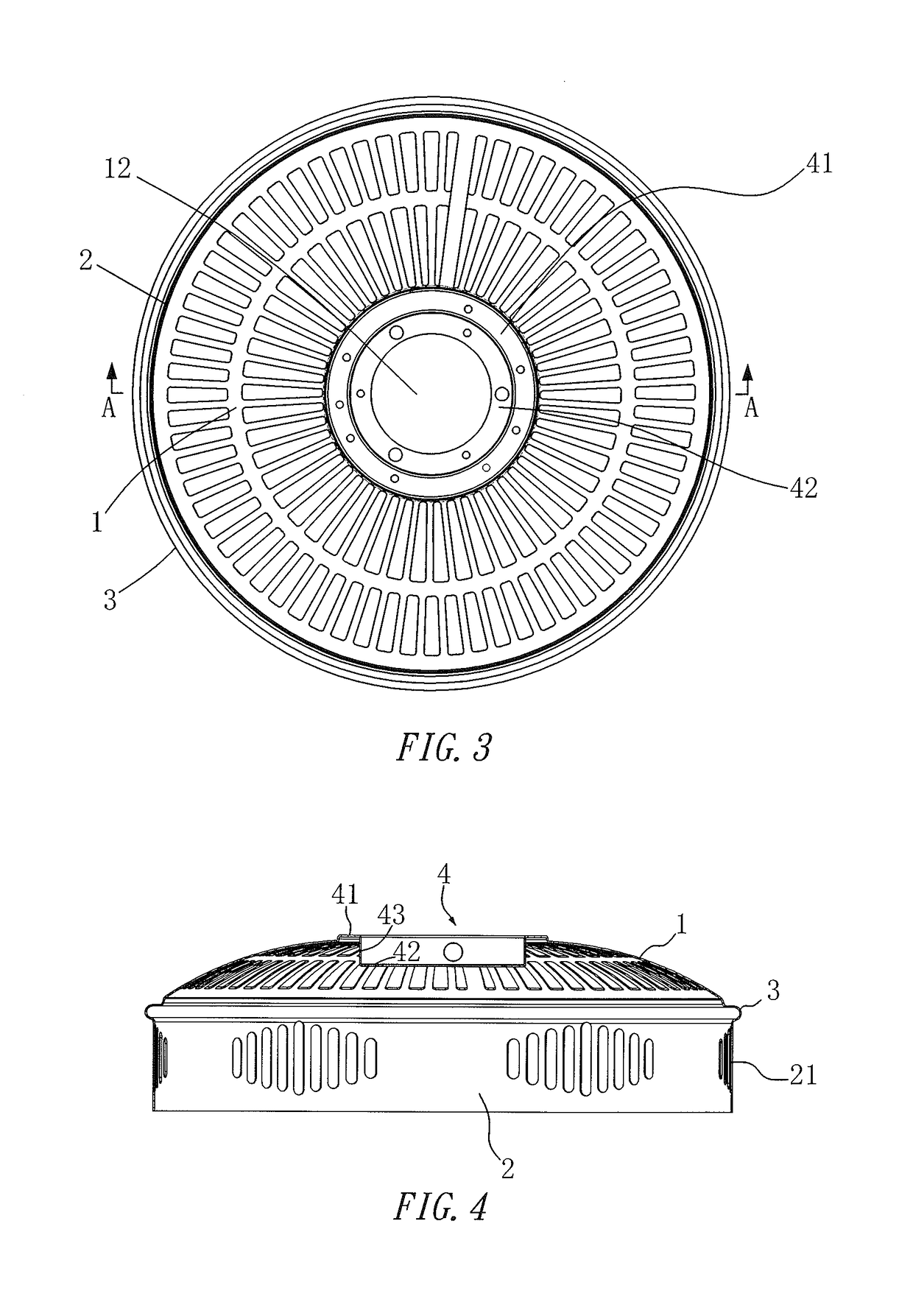

[0022]The present invention discloses an integrally formed fan guard and a manufacturing method of the integrally formed fan guard. With reference to FIGS. 1 to 5 for a fan guard of the present invention, the fan guard comprises a cover body 10 and a mounting part 4 fixed to the cover body 10.

[0023]The cover body 10 is manufactured by an integral forming method, and an air hole is formed on the cover body 10 for flowing air. The mounting part 4 may be fixed to the cover body 10 by a screwing or riveting method. The whole product does not require any welding process and automated process may be used to improve production efficiency and assure product quality.

[0024]Specifically, the cover body 10 includes a top side 1 and a circumferential side 2 integrally formed with each o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com