Modular pipe formation apparatus

a technology of modular pipe and pipe section, which is applied in the direction of corrugated articles, climate sustainability, other domestic articles, etc., can solve the problems of time-consuming coupling of pipe sections, substantial difficulty in coiling pipes to coils, and physical limitations of the size and bulk of cargo of transportation modes, so as to reduce the actual transportation cost, and reduce the cost of transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

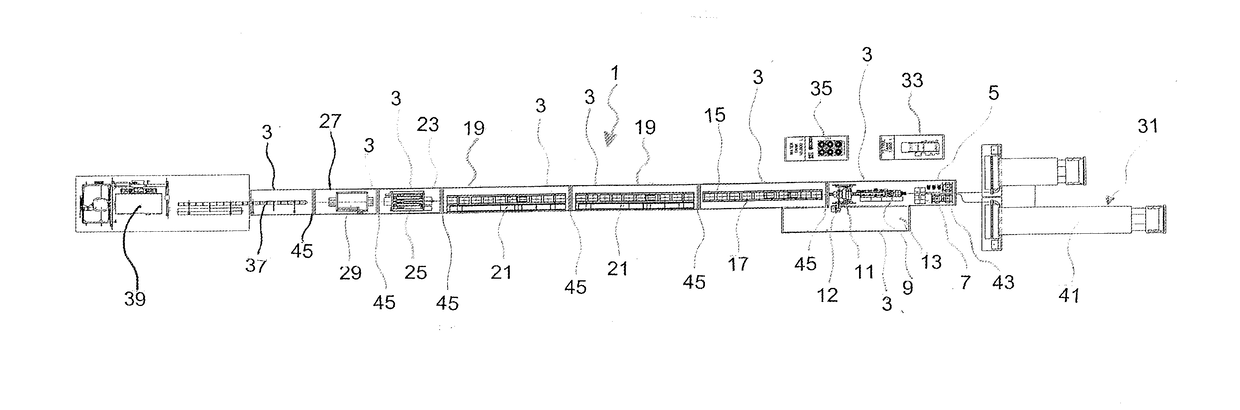

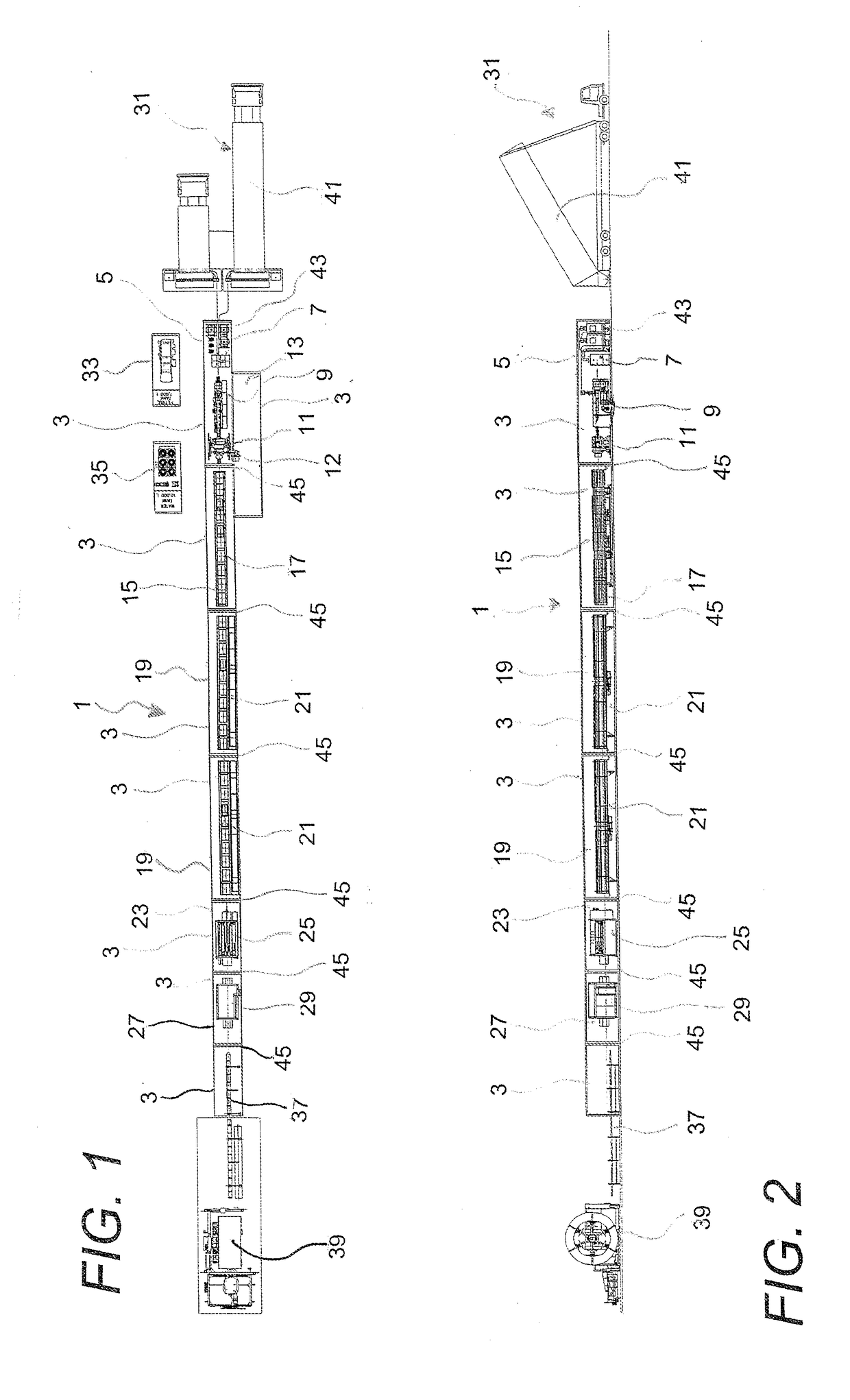

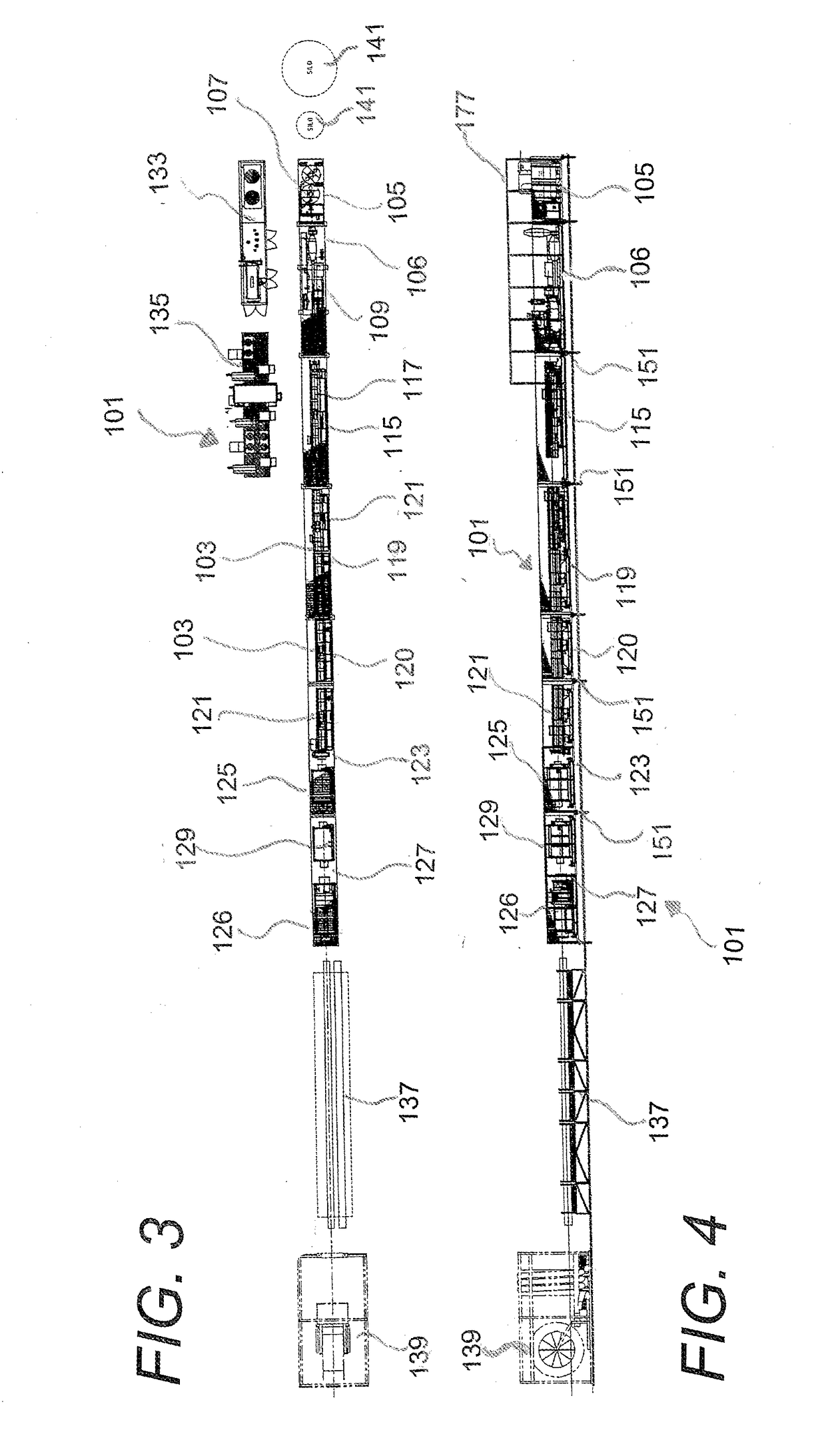

[0087]FIG. 1 illustrates a plan view of a modular plastic pipe formation apparatus 1 configured for smooth wall pipe production. The pipe formation apparatus 1 comprises a series of modules 3, each comprising modified shipping containers, within which are disposed components of the pipe formation apparatus. The modules 3 are coupled to each other in a predetermined layout, allowing the components therein to be aligned for pipe production.

[0088]In the first module 5, there is provided a raw material dryer 7, screw extruder 9 and a die head 11. In the second module 15, there is provided a vacuum water tank 17. The third and fourth modules 19 house water cooling tanks 21. The fifth module 23 houses a haul off caterpillar, and the sixth module 27 houses a cutter 29.

[0089]Other components for pipe production may include, a raw material feeding and storage component 31, a power generation unit 33, a chilling unit 35, pipe sliding table / tipping table 37 and a pipe coiler 39.

[0090]In pipe p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| corrosion resistant flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com