Motion platform having wire-shaped body winding mechanism

a technology of winding mechanism and motion platform, which is applied in the direction of arrangement using take-up reel/drum, etc., can solve the problems of limited application, unfavorable noise or vibration, and weak telescopic and bending deformation capabilities of elastic sleeves, and achieve the effect of causing no noise or vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

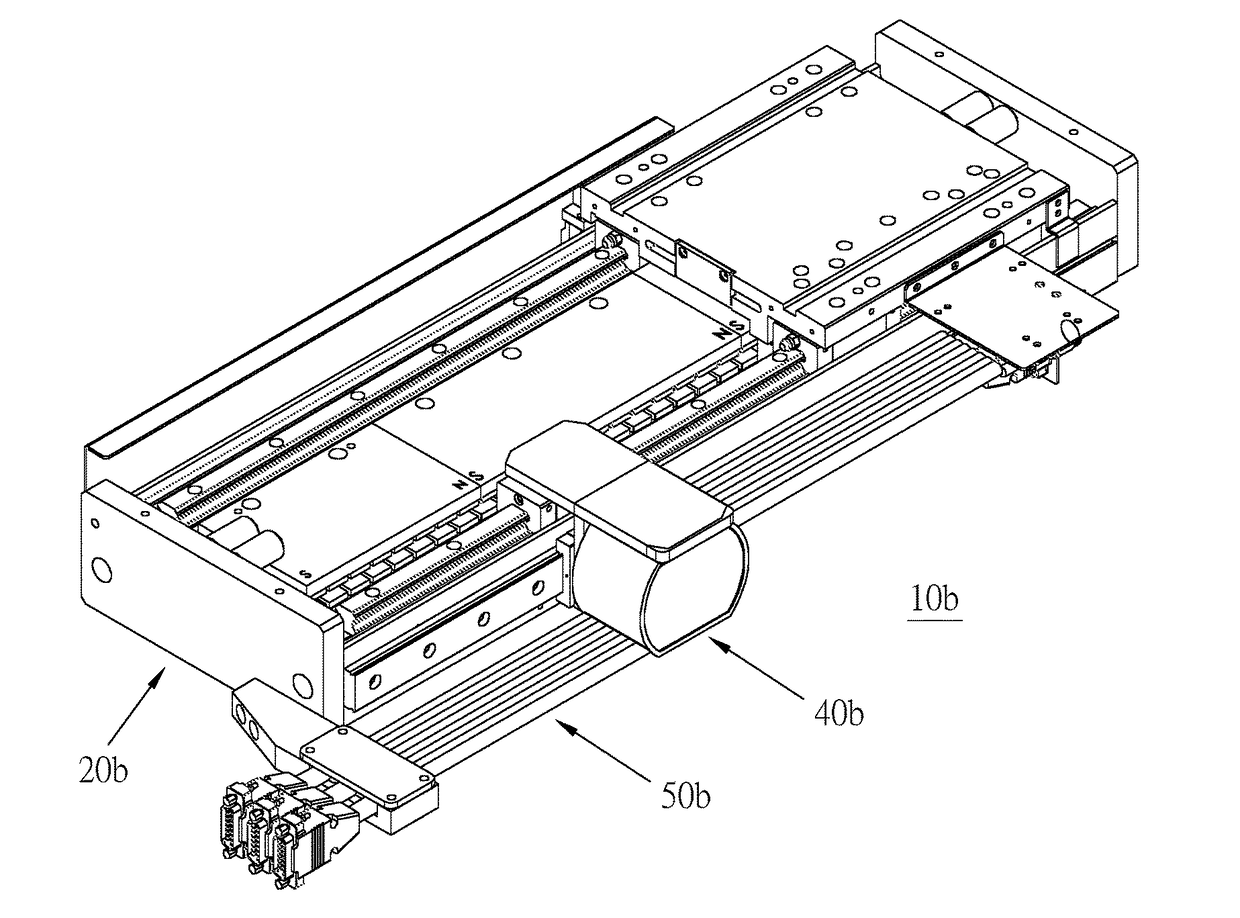

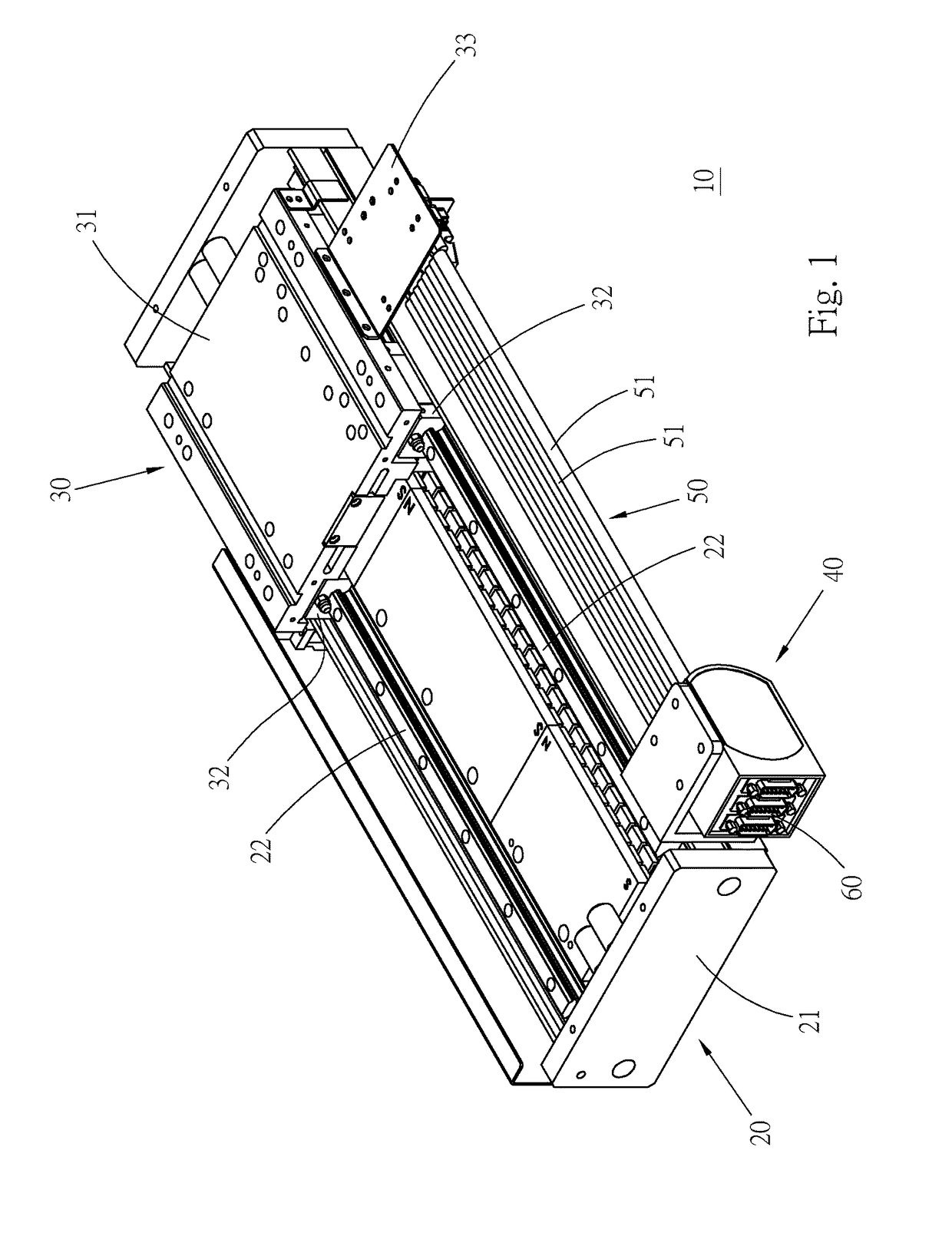

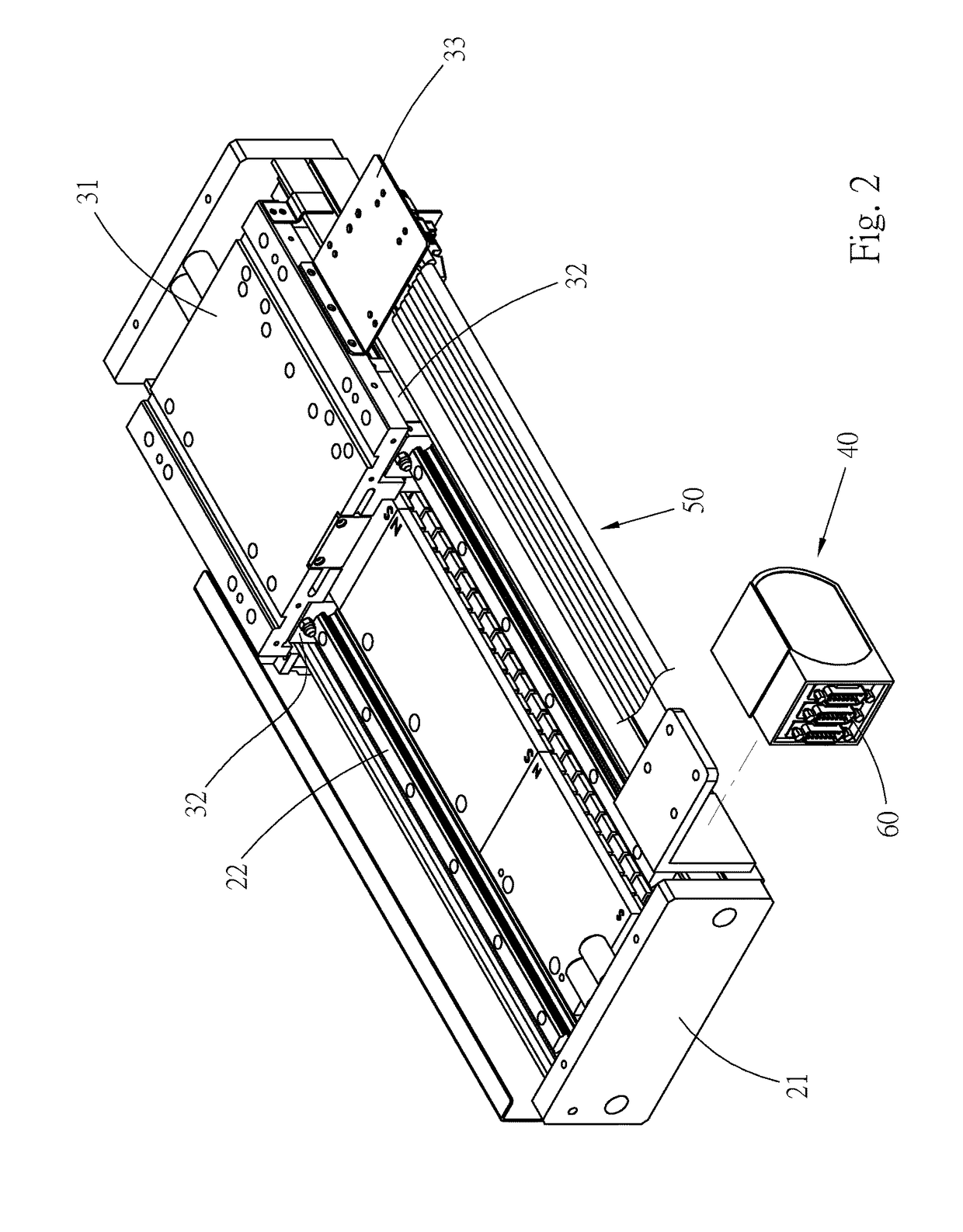

[0025]First, referring to FIG. 1 and FIG. 2, regarding a motion platform (10) having a wire-shaped body winding mechanism provided in a first embodiment of the present invention, for ease of description, only the technical content related to the main technical feature of the present invention is illustrated specifically, and other related subordinate arts apparent to persons of ordinary skills in the technical field of the present invention will not be described.

[0026]The structure of the motion platform (10) having a wire-shaped body winding mechanism includes a fixed seat (20), a movable seat (30), a winding mechanism (40) and a wire-shaped body (50).

[0027]The fixed seat (20) has a seat body (21) and two guide rails (22), where the seat body (21) is approximately a rectangular block, and the guide rails (22) are fixed in parallel on an upper seat surface of the seat body (21).

[0028]The movable seat (30) has a carrying table (31), a plurality of sliding blocks (32) and a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com