Impact Resistant Structures for Protective Garments

a technology of impact resistance and protective garments, applied in the field of protective garments, can solve the problems of requiring the use of diverse materials, and achieve the effect of improving the damping characteristics of the microlatti

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

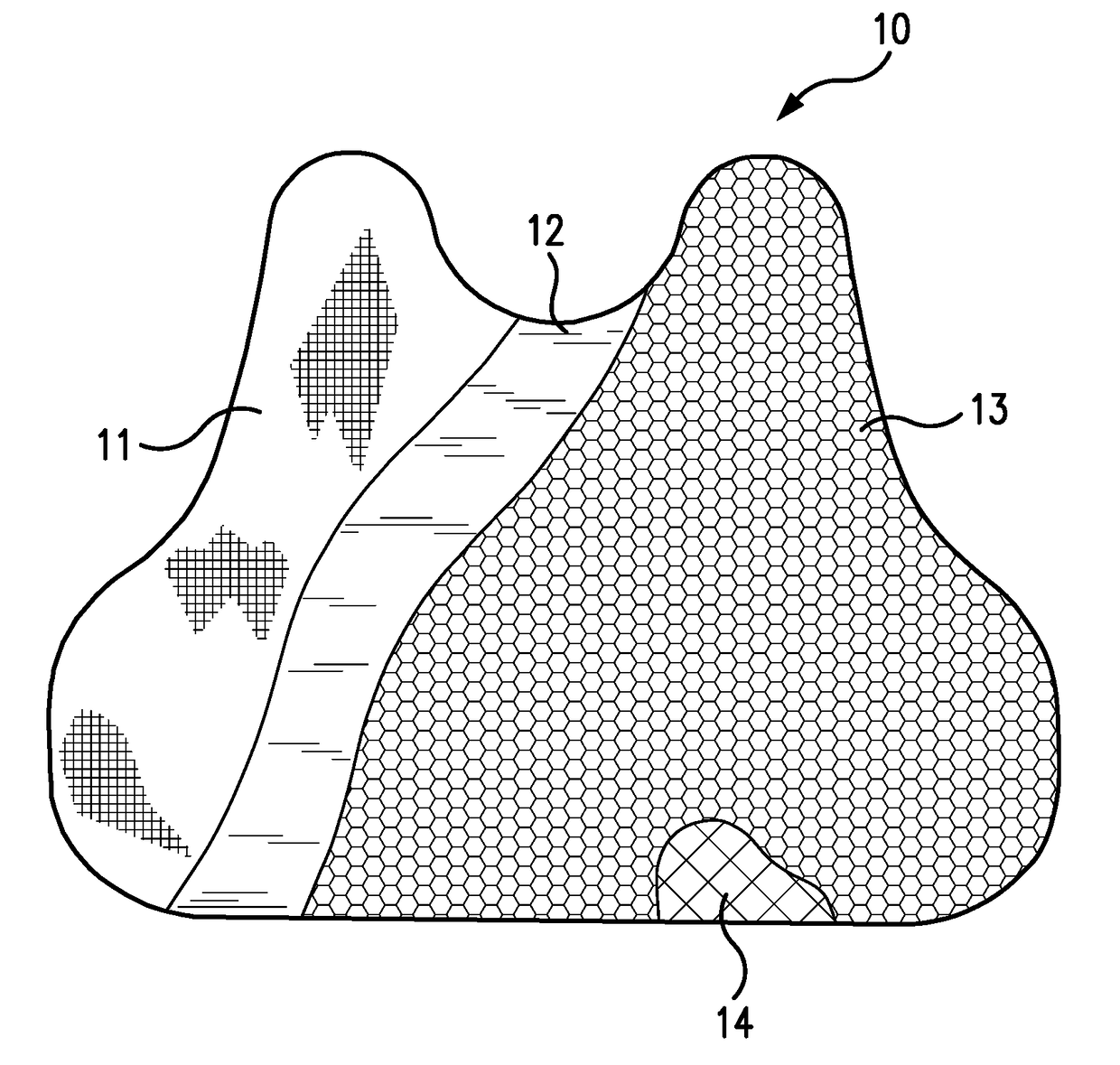

[0023]Referring to FIG. 1, an exemplary impact resistant breastplate structure 10 comprises a rigid, shock-deflecting outer layer 11, below which is a deformable, polymer-based microlattice shock-damping layer 12, below which is a semi-rigid, polyurethane honeycomb lattice dissipative layer 13, below which is a lower shock-absorbing fabric layer 14.

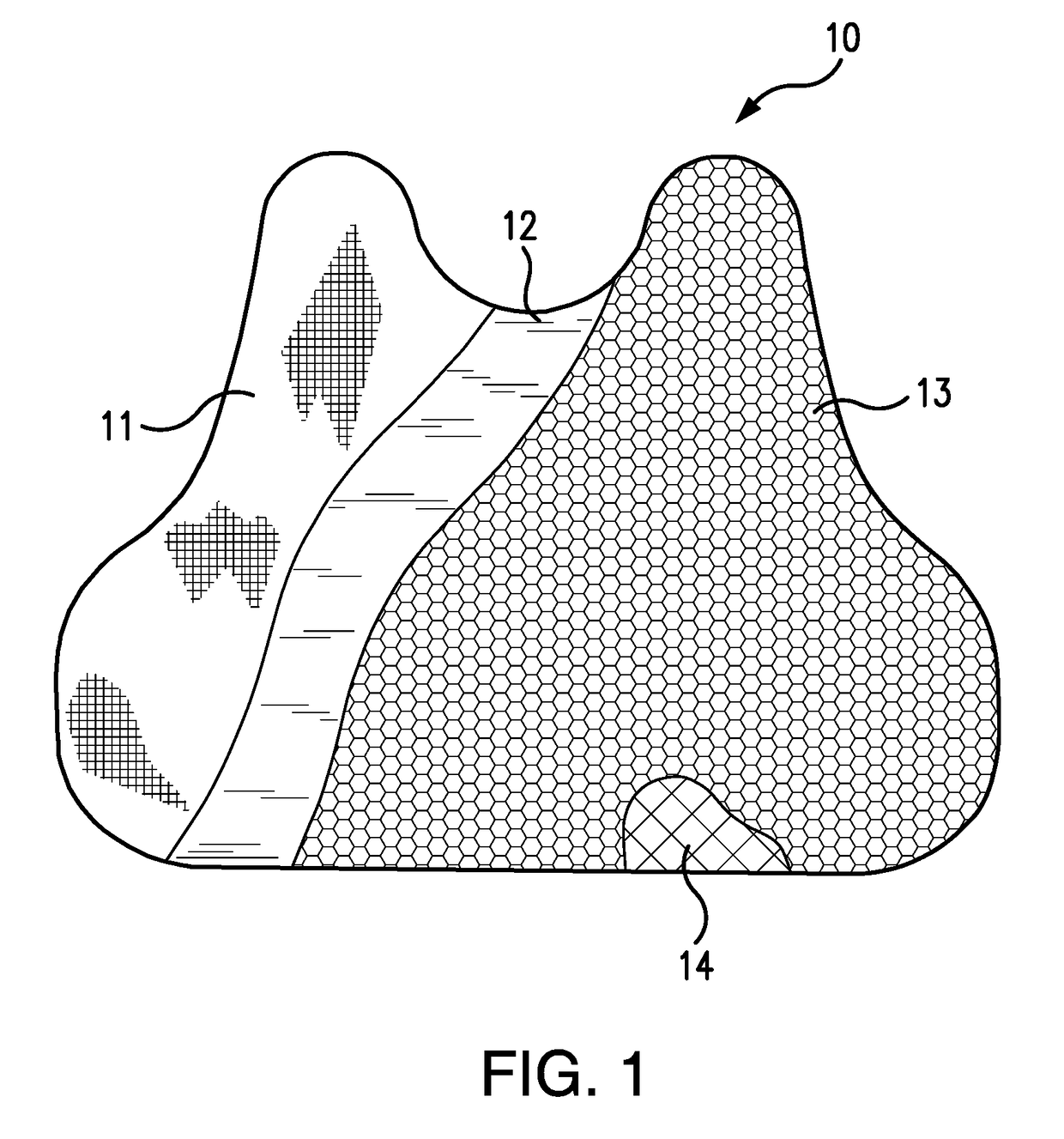

[0024]As shown in FIG. 2A, the microlattice layer 12 comprises a three-dimensional network of hollow nanotubes, preferably having tube diameters less than 1 mm. The nanotubes microscopic structure is depicted in FIGS. 2B and 2C, in which the microlattice is under increasing compression, with deformation progressing from incipient buckling at the nodes 15 to more advanced buckling 16. The buckling at the nanotubes' nodes damps impact forces, and the extremely small aspect ratio of the nanotubes' wall thickness to their diameter enables nearly full deformation recoverability.

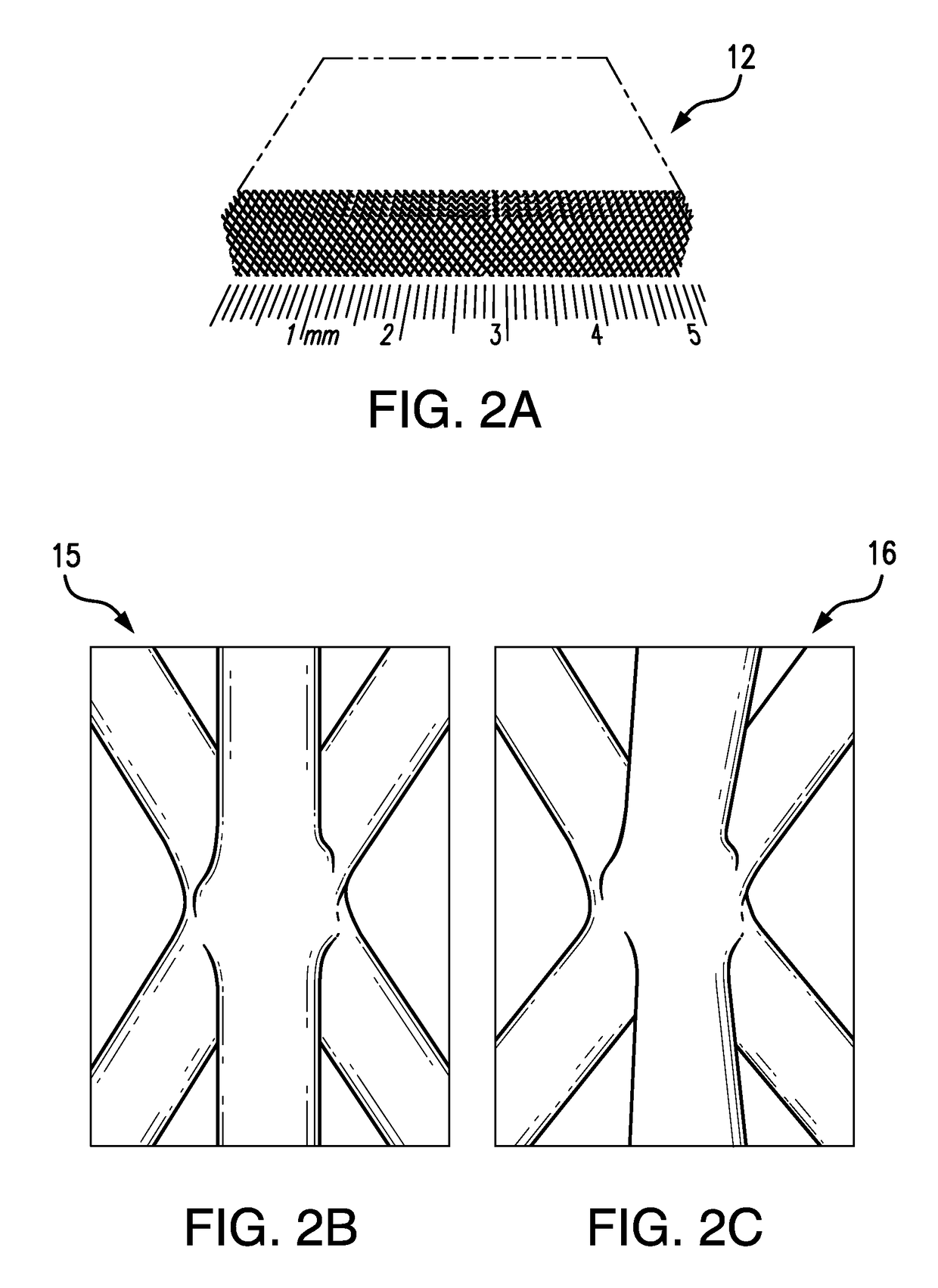

[0025]FIG. 3 depicts the semi-rigid, polyurethane honeycomb lattic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com