Closure system for bottles comprising a stopper and a sealing element

a bottle and sealing element technology, applied in the field of bottle sealing system, can solve the problems of not being reusable, unable to be generally reattached, and unable to achieve proper sealing any longer on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

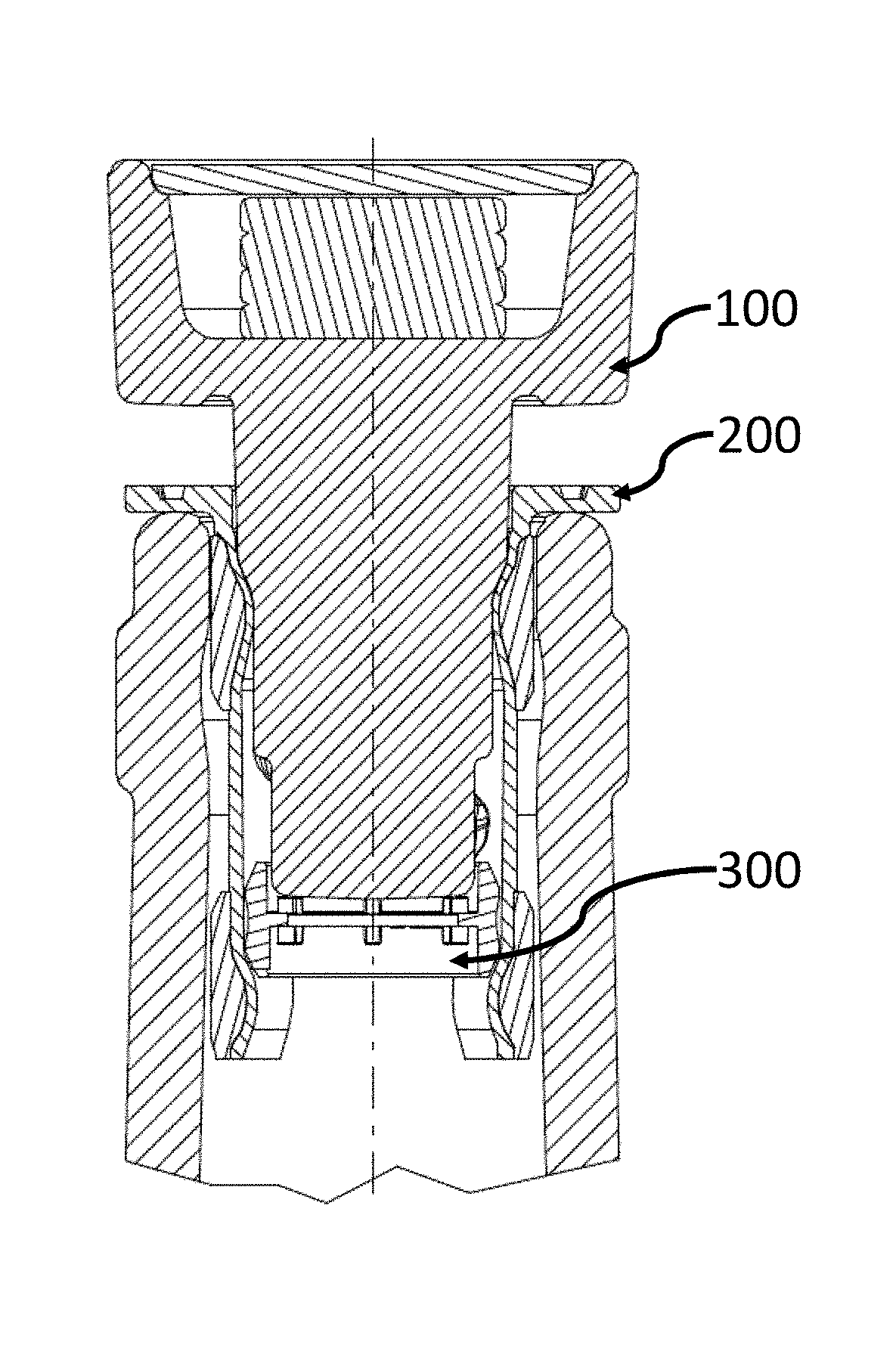

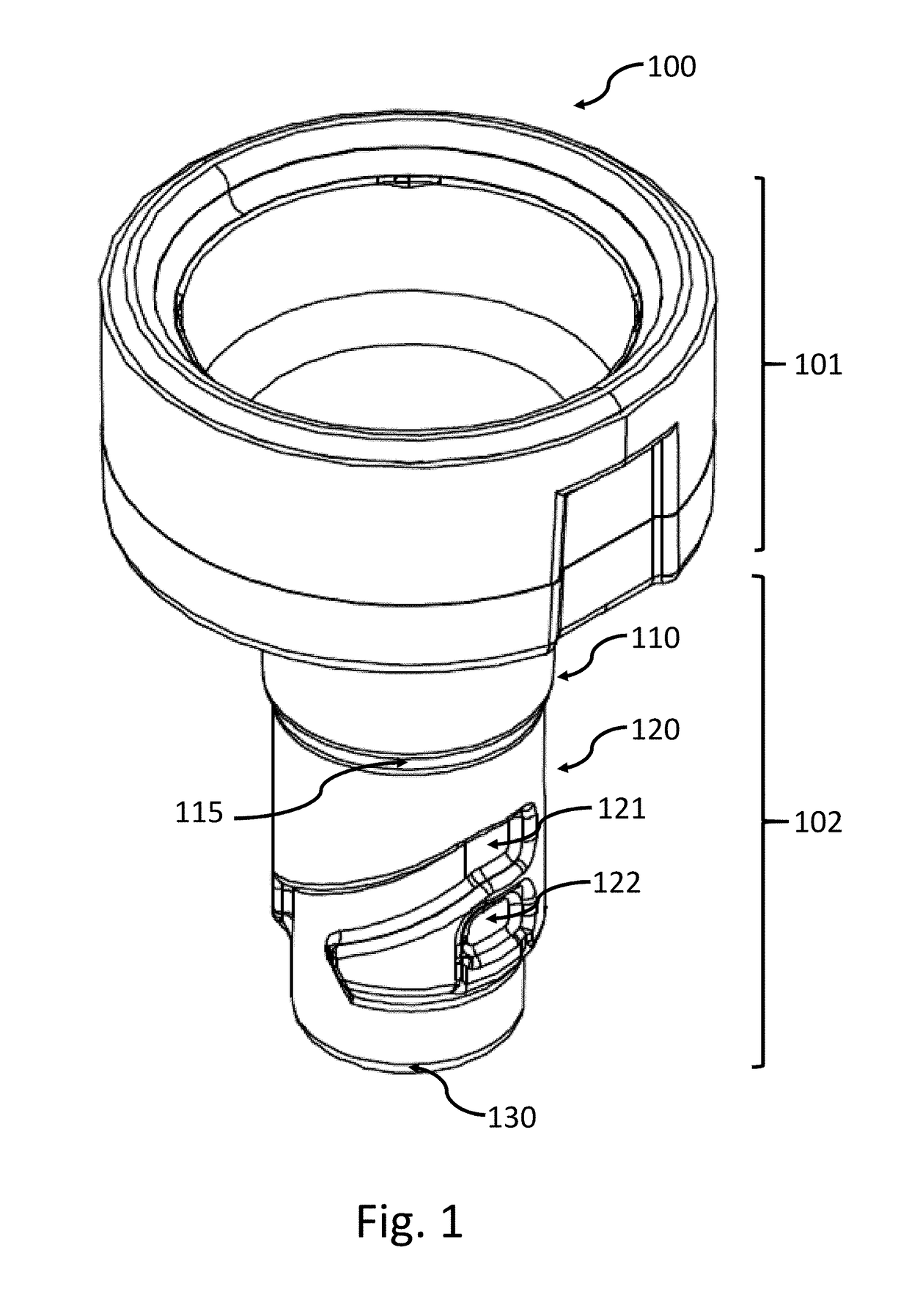

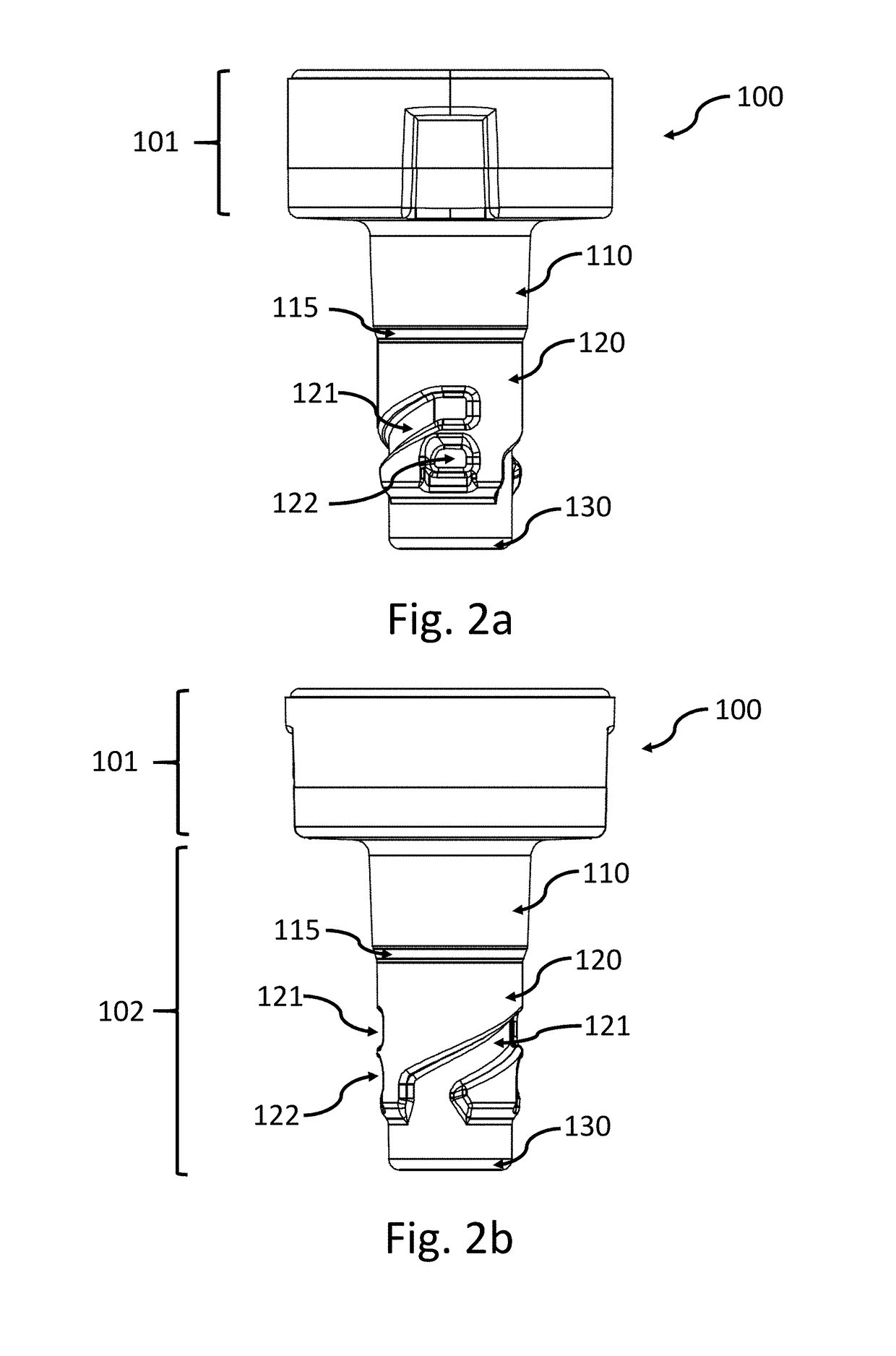

[0579]The following detailed description relates to a closure system for a bottle designed for commercial bottling of a beverage or liquid food, preferably a wine bottle. The closure system comprises a stopper and a sealing element, which is separate from the bottle and from the stopper. The stopper will be described with reference to FIGS. 1 to 2b, the sealing element will be described with reference to FIGS. 3 to 7b and the functioning of the closure system will be described with reference to FIG. 8. Further embodiments will be described with regard to FIGS. 9 to 13.

[0580]The stopper of the closure system comprises a stopper part for introduction into a mouth of the bottle and a head part for remaining outside of the mouth, wherein the head part has a diameter which is larger than that of the stopper part. The closure system is configured such that the sealing element may be forced against the inner wall of a mouth of the bottle, upon introduction of the stopper into the mouth, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com