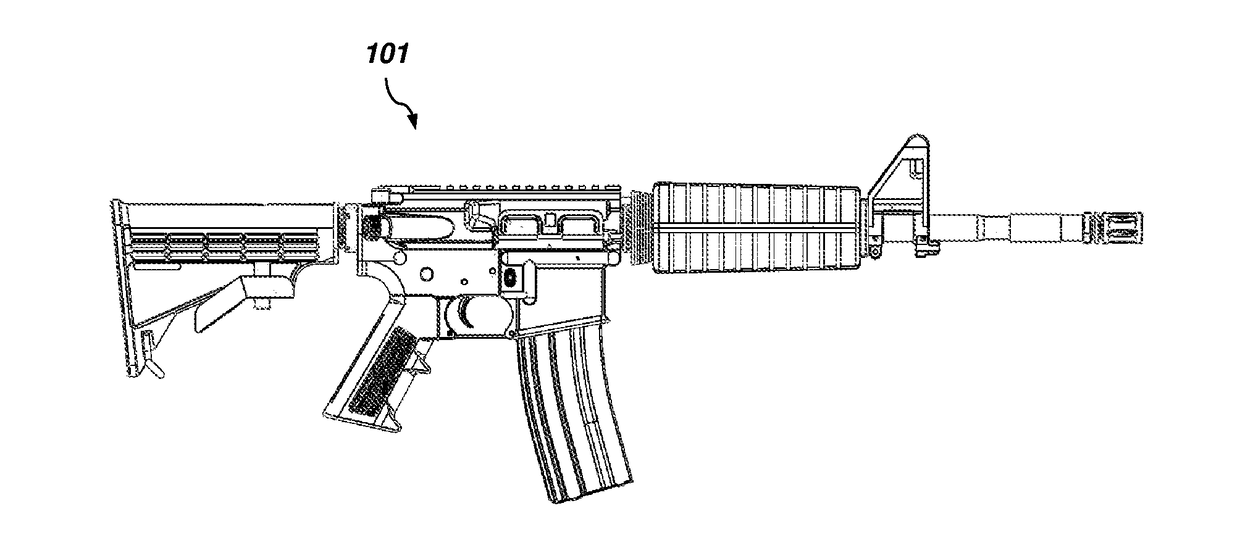

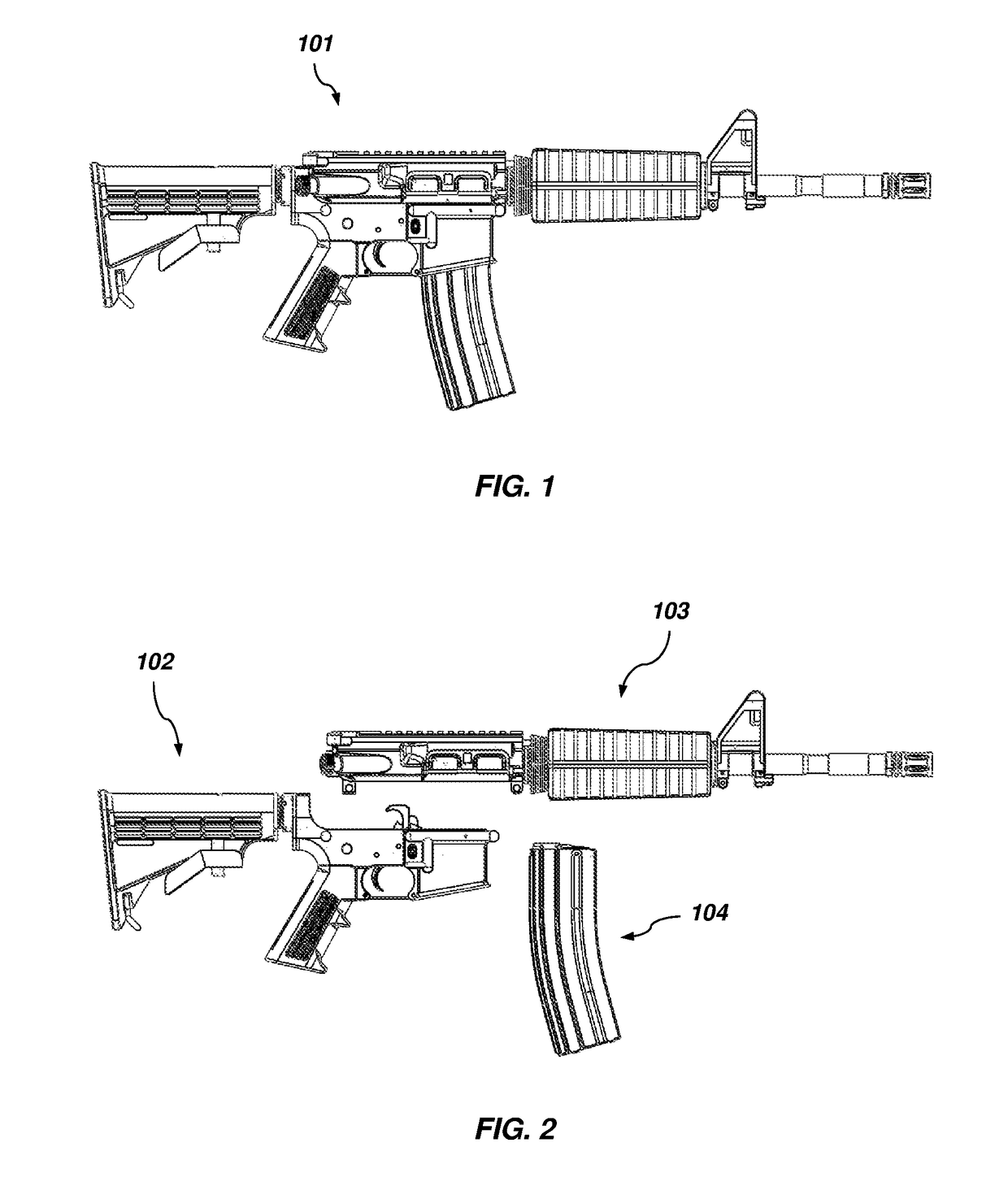

Ar based autoloading shotgun with a detachable magazine

a detachable magazine and shotgun technology, applied in the field of shotgun type firearms, can solve the problems of inability to support fixed magazines, inability to use gas operated mechanisms, and inability to inherently adapt to shotgun platforms, and achieve the effect of facilitating the meshing of the protruding locking lugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

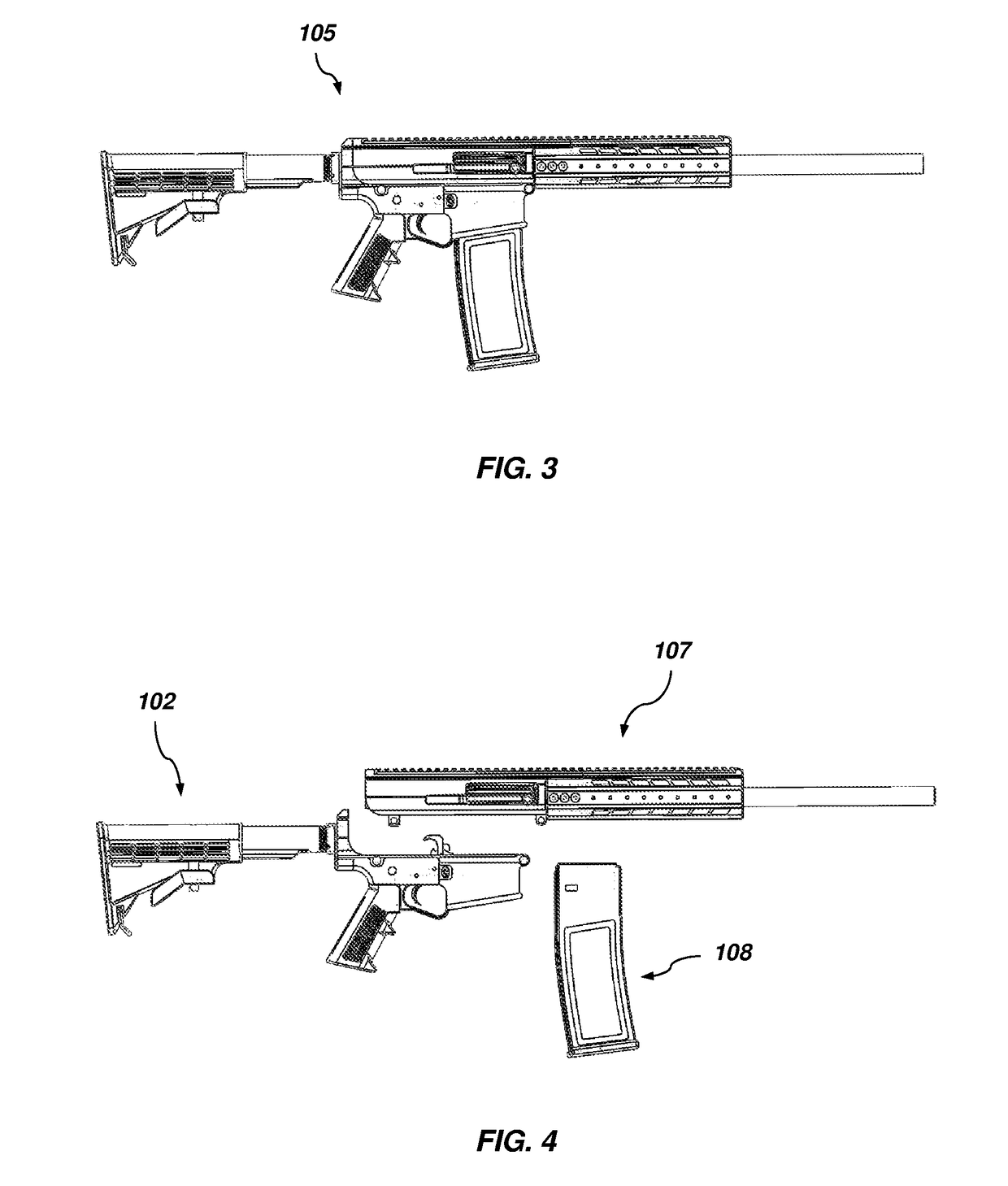

[0041]FIGS. 3 through 15 illustrate embodiments of systems, techniques, methods, and devices to enable the use of standard commercially available rimmed shotgun ammunition in an AR rifle converted to an AR shotgun. The embodiments are not limited to any specific type or gauge (caliber) of standard commercially available rimmed shotgun ammunition. The dimensions of the AR shotgun upper receiver assembly in conjunction with the AR shotgun ammunition detachable magazine assembly would be altered accordingly to accommodate the desired shotgun firearm ammunition gauge (caliber). In addition to utilizing the unaltered AR rifle upper receiver assembly, the AR rifle to AR shotgun firearm conversion according to the embodiments may be considered AR compatible in that, while being capable of loading, firing, ejecting and reloading standard commercially available shotgun ammunition, the shotgun firearm utilizes the same ergonomic controls, parts commonality, and operational functionality as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com