Unit Cell Titanium Casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

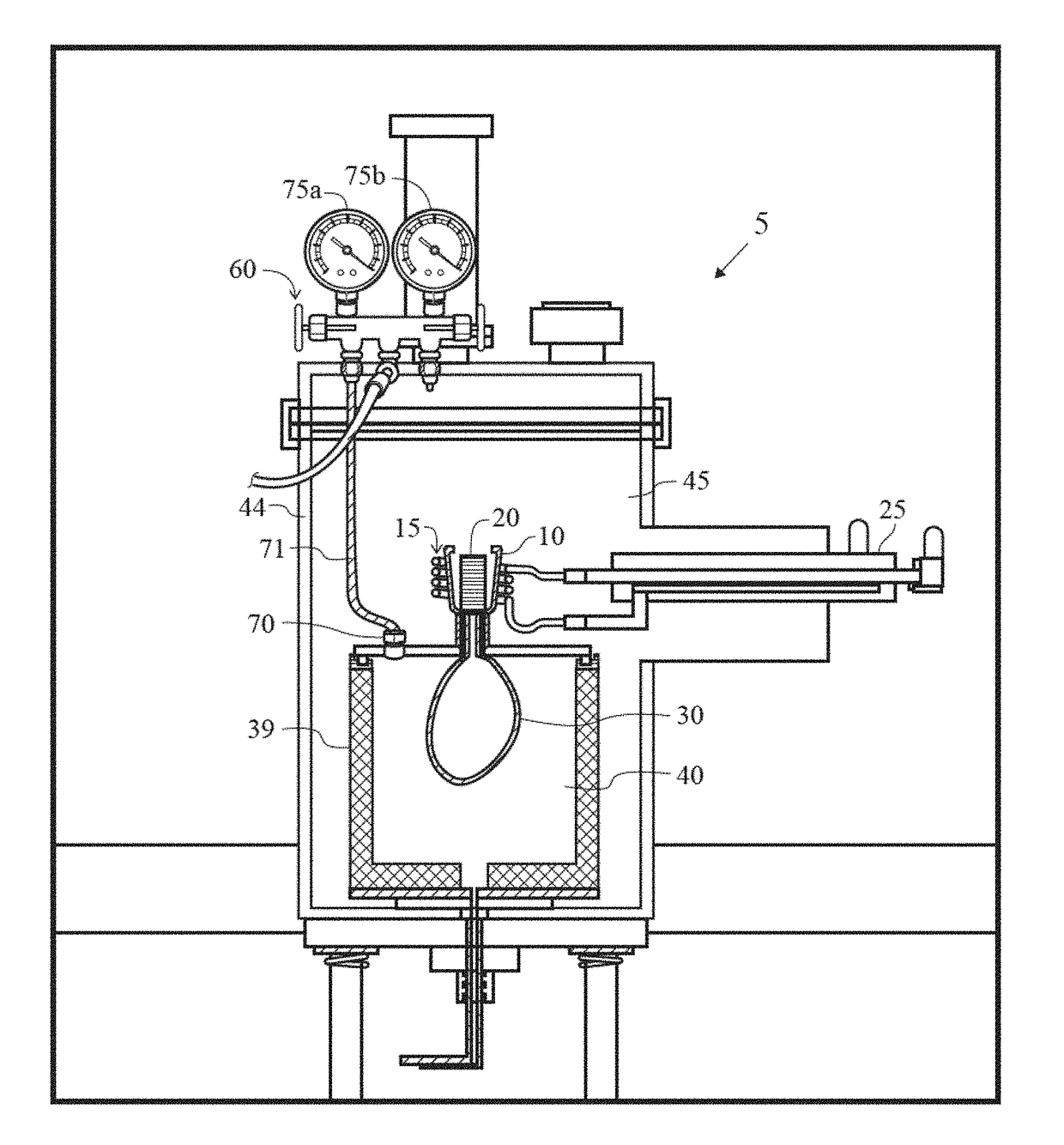

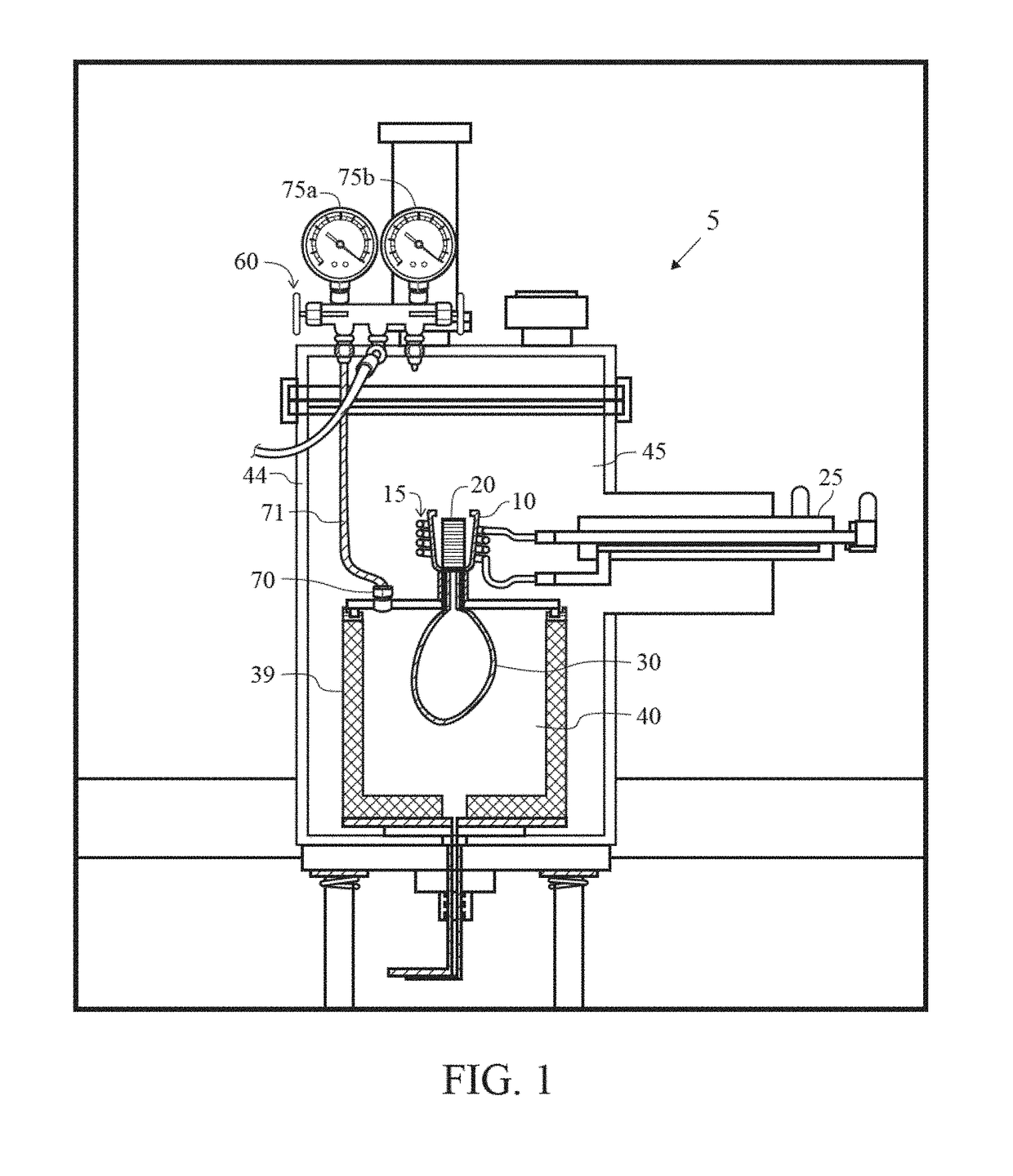

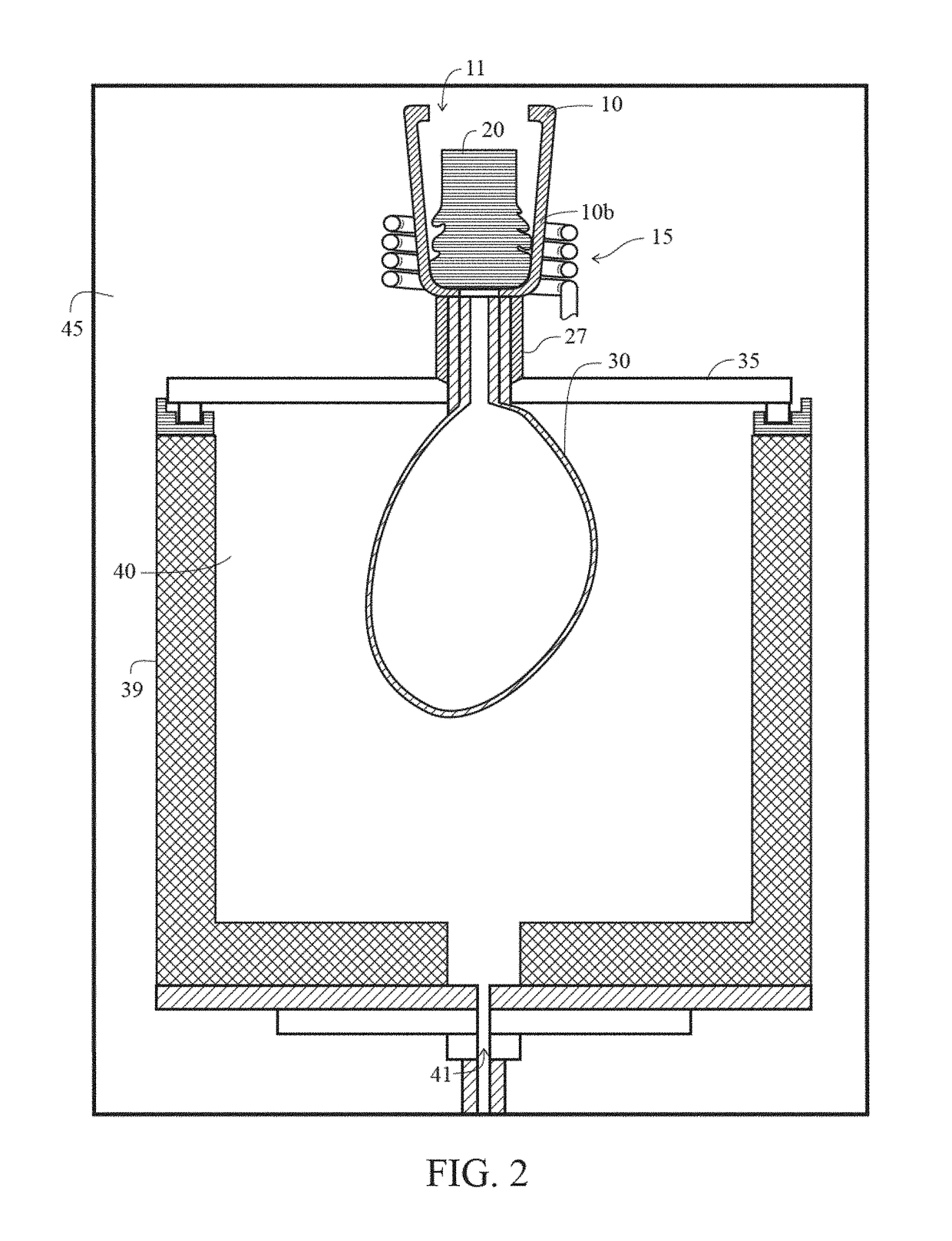

[0037]Utilizing the two chamber casting system, one of the primary tenets is the use of a crucible in order to contain the target material during melt and prior to evacuation into the pattern mold. In order to optimize the effectiveness of the crucible while providing the maximum processing robustness, multiple Yttria-based “primary” shell layers is preferably used (along with multiple back-up layers in order to build up overall strength). There should be between two and ten primary layers and they should be 0.001″-0.020″ in thickness and be comprised of a binder: slurry ratio between 1:1 and 1:2. This will allow for the best performance out of a single use crucible and still allow for the processing robustness of having multiple layers which can serve to reinforce each other and avoid voids in a single layer caused by processing issues.

[0038]Utilizing the two chamber casting system, one of the primary tenets is the use of a crucible in order to contain the target material during me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com