Rucksack

a backpack and back system technology, applied in the field of backpacks, can solve the problems of inconsistent products, high labor costs, and high cost of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

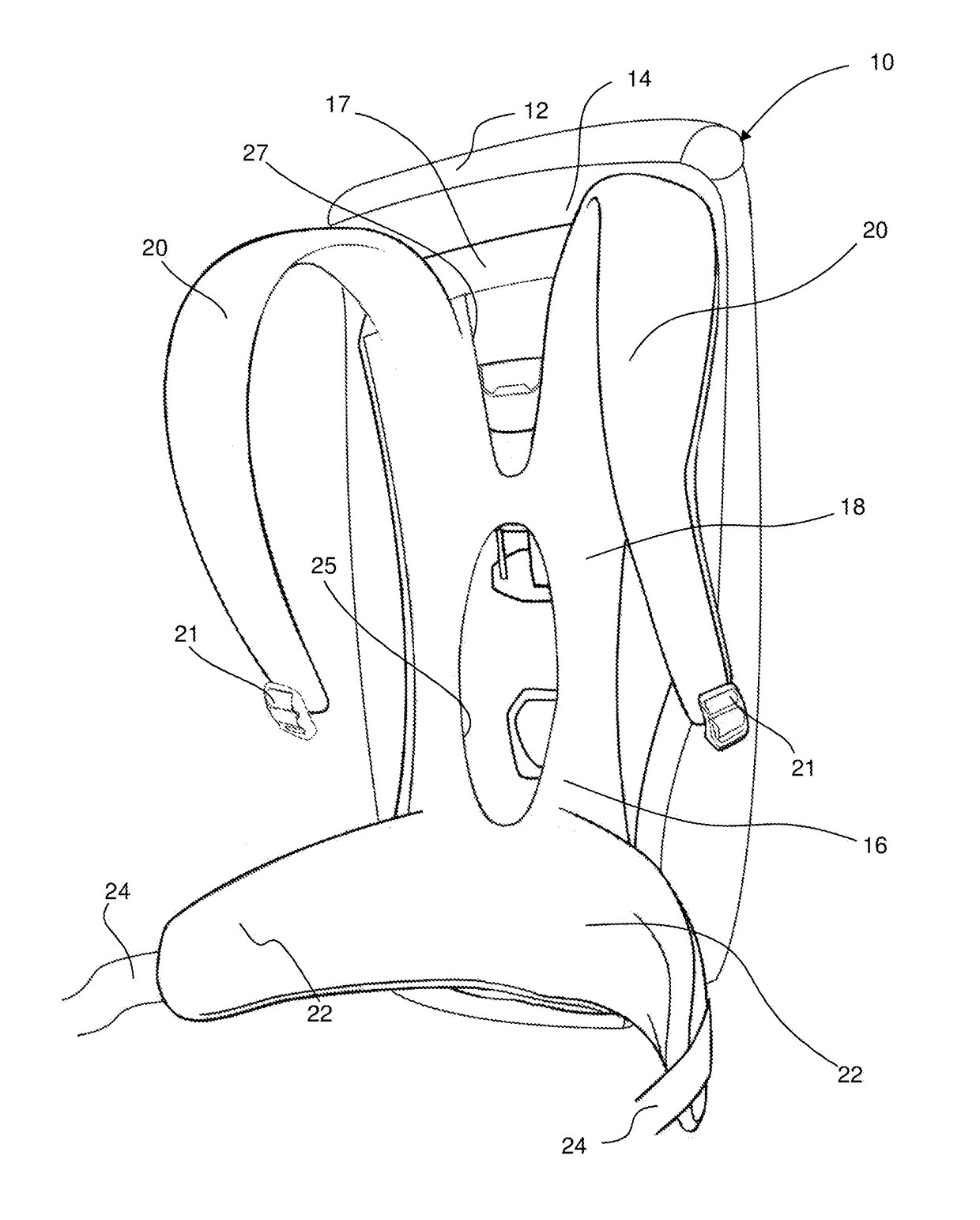

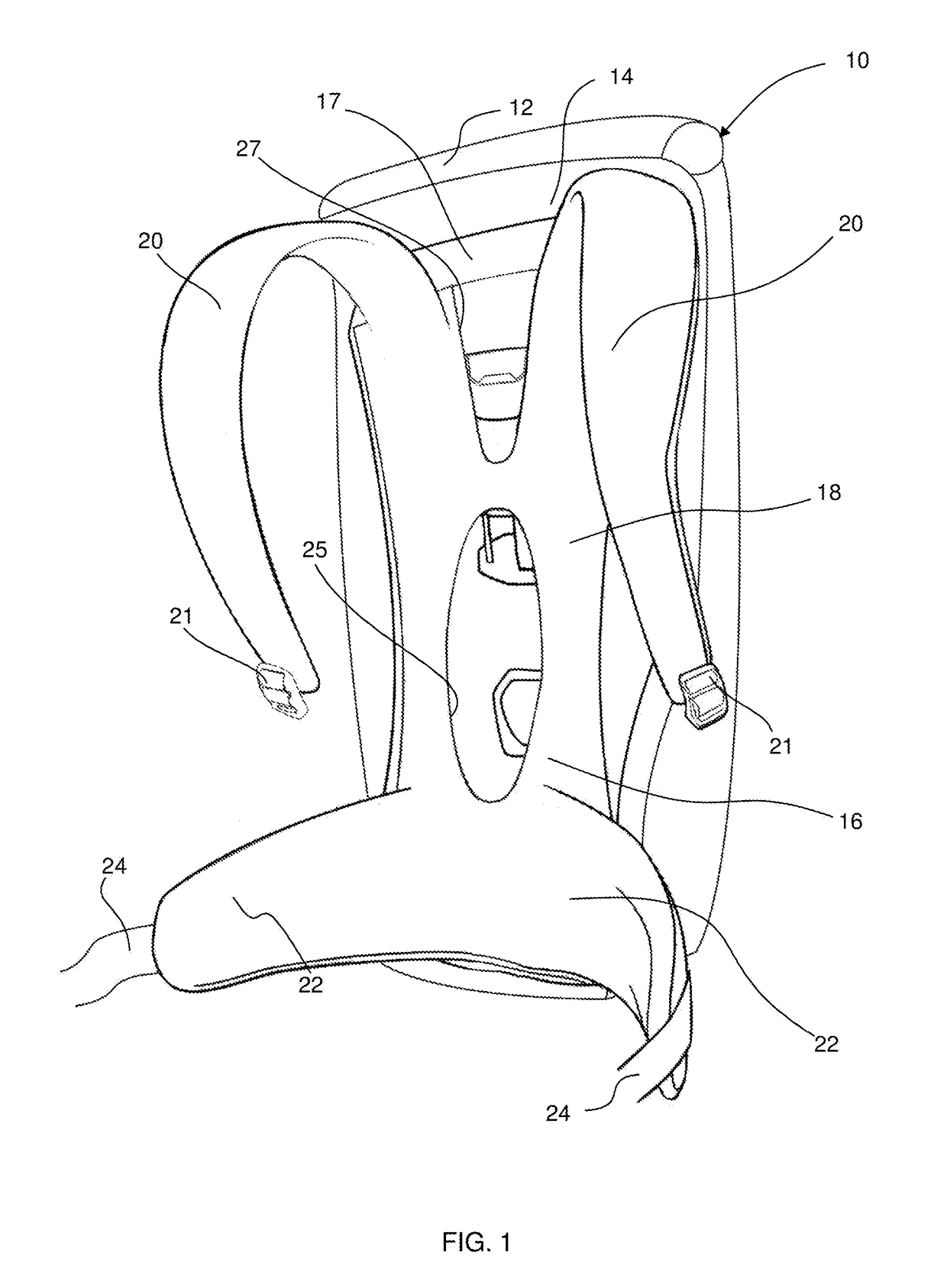

[0059]Referring to FIG. 1, a rucksack is indicated generally at 10. The rucksack 10 comprises a storage compartment 12, the storage compartment 12 having a rear face 14. In this embodiment, a harness 16 forms part of a back system 17, the back system 17 being attached to the rear face 14 of the storage compartment 12.

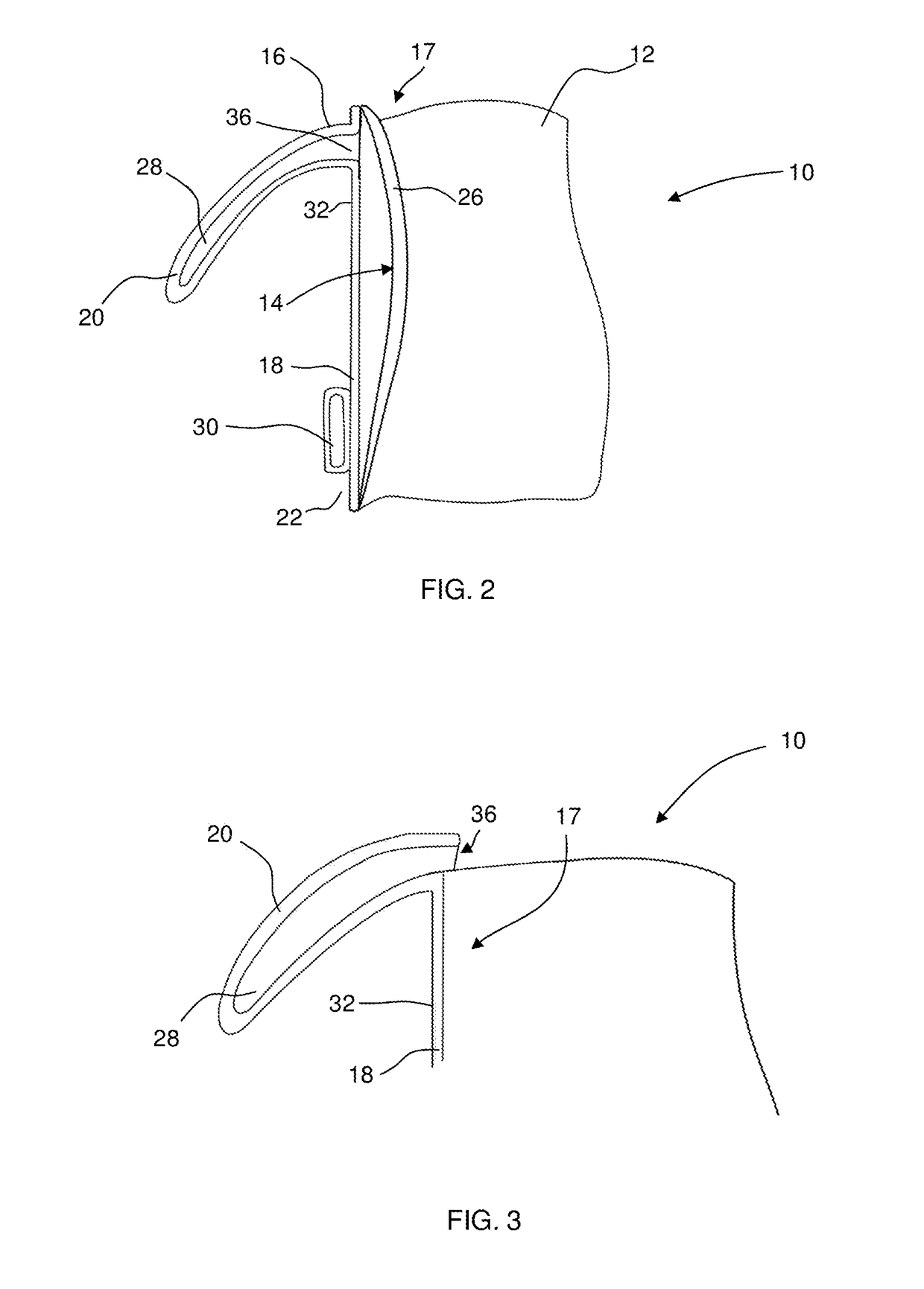

[0060]The harness 16 has a back portion 18 which is generally planar and extends substantially vertically in use. The back portion 18 is attached to the storage compartment at top and bottom ends of the rear face 14. The rear face 14 of the storage compartment forms a bowed arrangement with the rest of the back system 17, to define an air gap between the back portion 18 and the rear face 14 of the rucksack 10 when the back system 17 is attached to the rucksack 10. The rear face 14 can be provided with a spacing apparatus in the form of at least one resilient stiffening element 26 that extends at least part of the length of the rear face 14. In use, the back portion 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com