Suspension device and system for a washing machine

a technology of suspension device and washing machine, which is applied in the direction of washing machine, washing apparatus, textiles and paper, etc., can solve the problems of difficult control of manufacturing process, large dimensional precision of used foam, and the movement of the washing tank, so as to achieve greater functional stability of the damping mechanism and process simplicity. the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following description will be based on a preferred embodiment of the invention. As will be evident to the skilled person, however, the invention is not restricted to this particular embodiment.

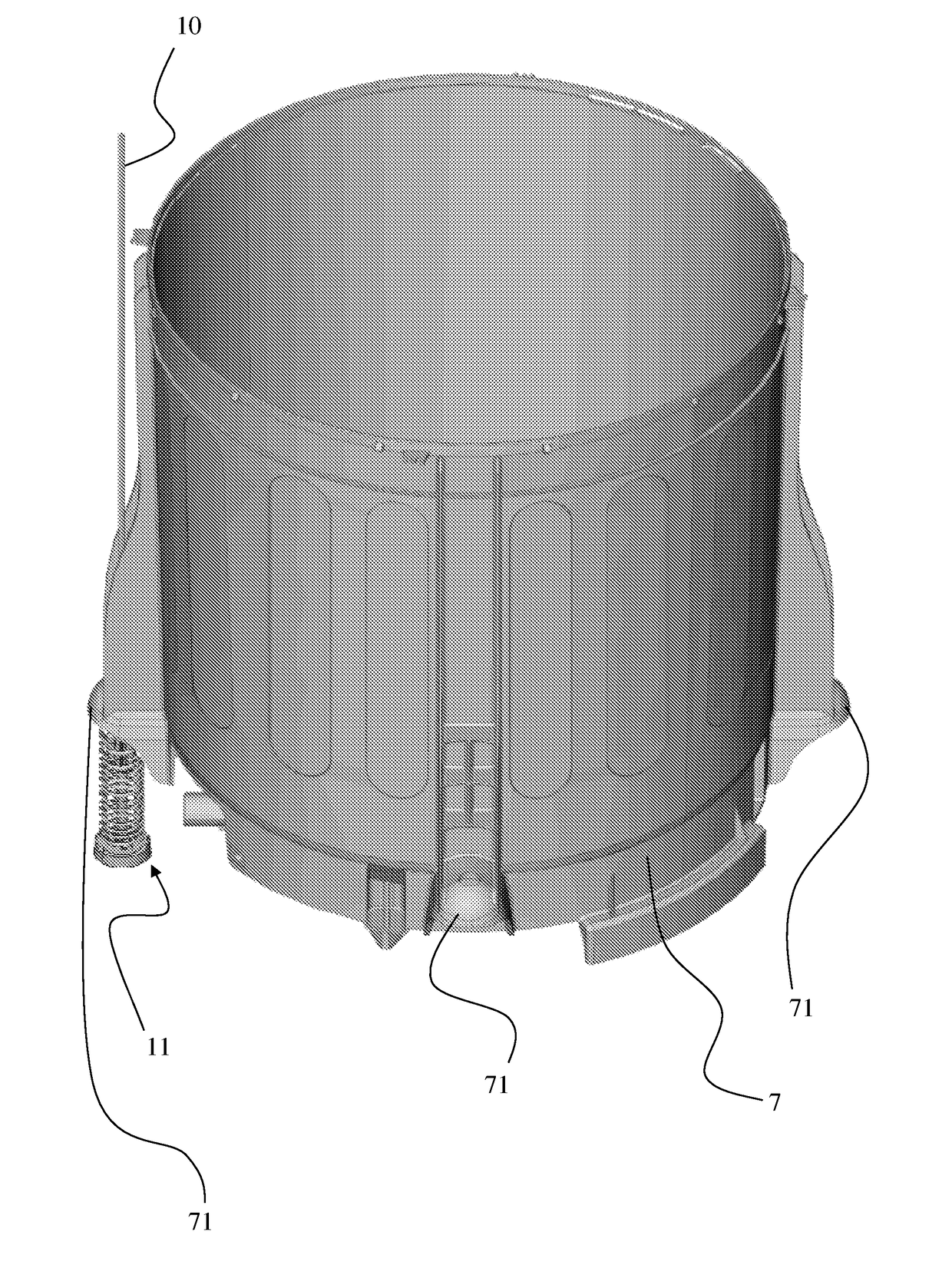

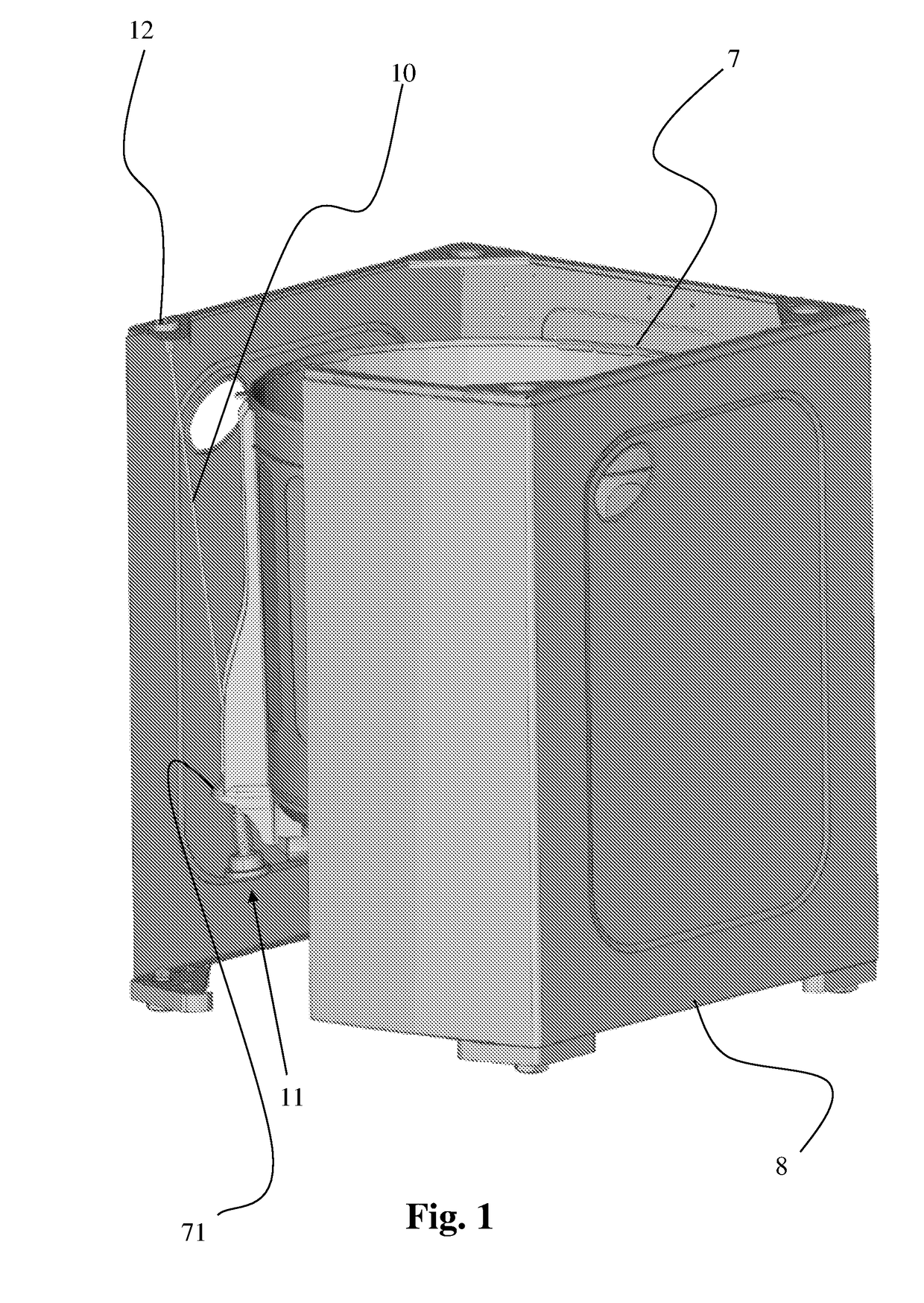

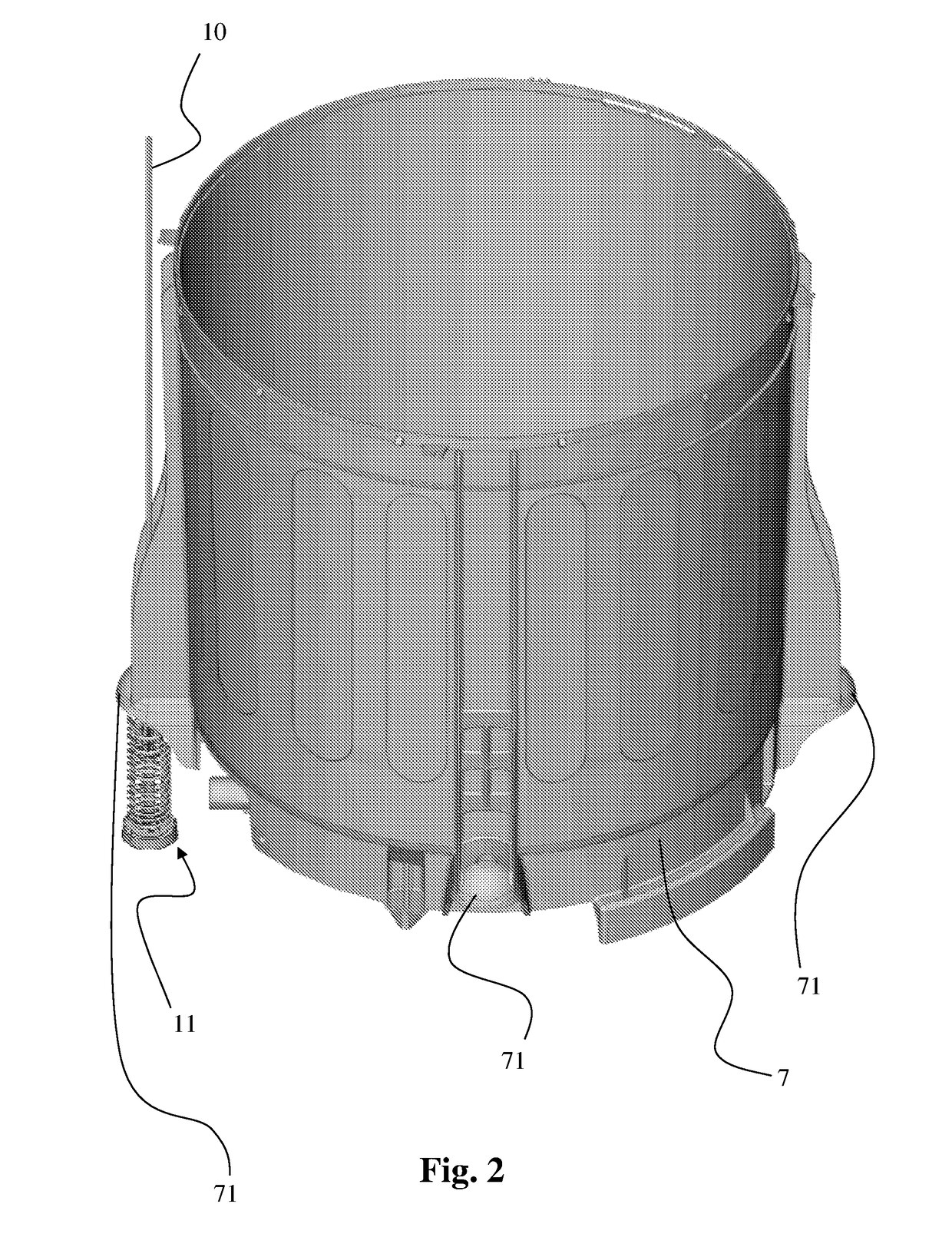

[0020]FIG. 1 illustrates an optional configuration of the present invention, wherein the suspension system for the washing machine comprises four 10 supporting shafts (wherein only one shaft is illustrated), whose upper ends 12 are coupled to the structural cabinet 8 of the washing machine. The lower ends of the shafts 10, in turn, are connected to suspension devices 11.

[0021]As can be noted, the tank 7 of the washing machine is maintained in suspension by the shaft / suspension device assemblies 10 / 11. More specifically, the weight of the tank 7 is supported by the suspension devices connected to the lower ends of the shafts 10. Therefore, vibrations of the tank 7 caused by the process of washing or centrifuging clothes, for example, are minimized by the suspension devices 11, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com