Vane pump

a technology of vane pump and working fluid, which is applied in the direction of rotary/oscillating piston pump components, machines/engines, liquid fuel engines, etc., can solve the problems of unsatisfactory effect, cavitation or noise, and the inability to smoothly suction the working fluid into the rotary chamber rs, so as to minimize damage to the vane or occurrence, smooth drawing of working fluid, and excellent flow rate and volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0046]First, referring to FIG. 6, an outer cam ring 100 of the first embodiment will be described.

[0047]The outer cam ring 100 of the first embodiment has, on a portion thereof corresponding to the side to which the working fluid is introduced, a rectangular through slit 100h which extends in the circumferential direction thereof.

[0048]Specifically, the upper end part 111 of the outer cam ring 100 has one portion in which the rectangular through slit 100h is formed, and which is formed in the same height as the remaining portion thereof, and the lower end part 113 of the outer cam ring 100 has one portion, in which the rectangular through slit 100h is formed, and which is formed in the same height as the remaining portion thereof. That is, the outer cam ring 100 is formed such that the upper and lower portions thereof are formed to be flat overall.

[0049]Meanwhile, the upper end part 111 of the outer cam ring 100 having the through slit 100h formed therein and the lower end part 113 ...

second embodiment

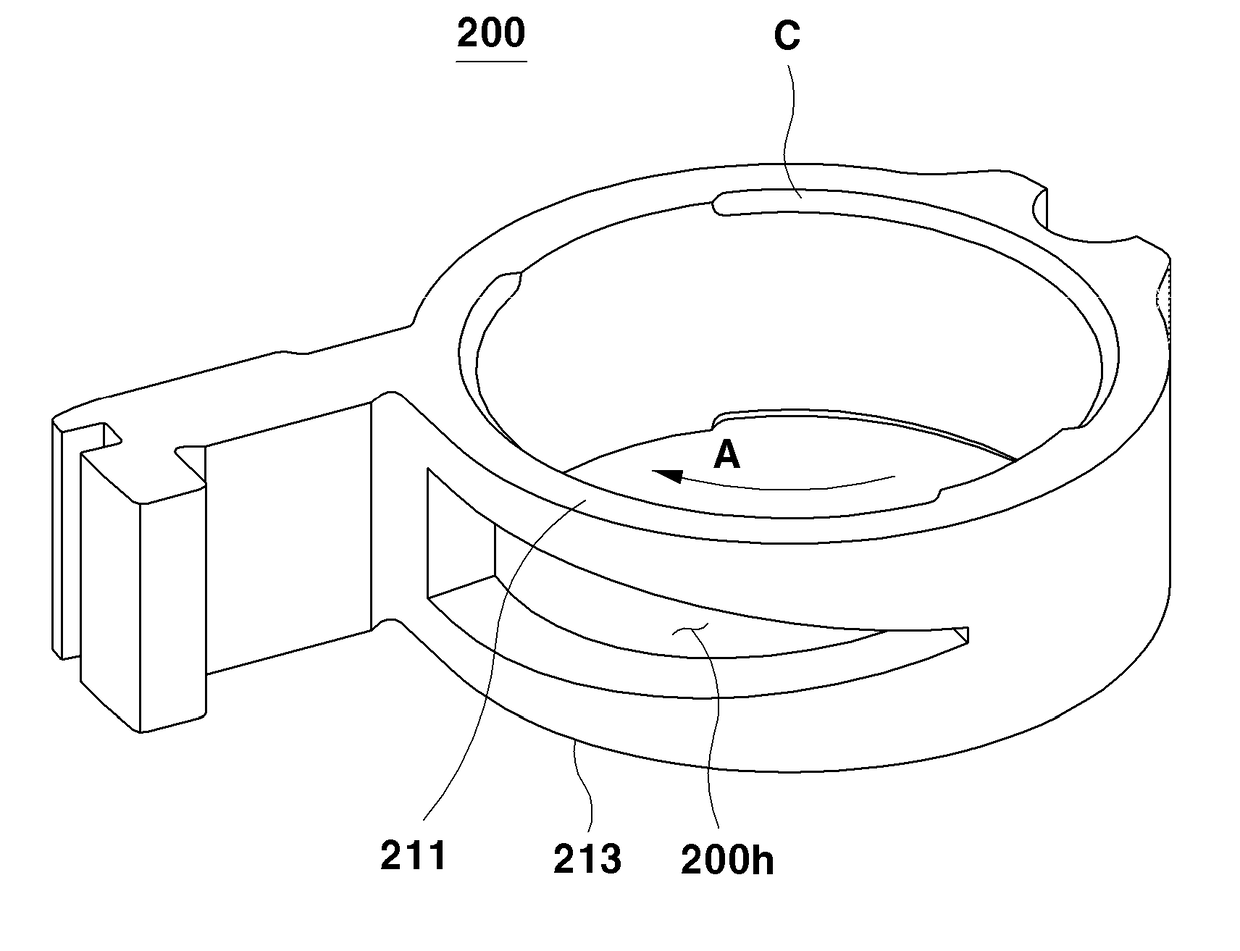

[0052]Next, referring to FIG. 7, an outer cam ring 200 of the second embodiment will be described.

[0053]The outer cam ring 200 of the second embodiment has, on the corresponding portion of the outer cam ring 200 corresponding to the side where the working fluid is introduced into a rotary chamber, a through slit 200h which has a shape of an approximate isosceles triangle and extends in the circumferential direction of the outer cam ring 200. That is, an upper end part 211 and a lower end part 213 of the outer cam ring 100 respectively have portions which have the through slit 200h formed therein and are formed to be vertically symmetrical to each other.

[0054]Specifically, the upper end part 211 and the lower end part 213 of the outer cam ring 200 have portions which have the through slit with an isosceles triangle shape 200h formed therein, the portions being formed to have heights which gradually increase in the opposite direction to a moving direction A of he working fluid, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com