Three dimensional printing system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

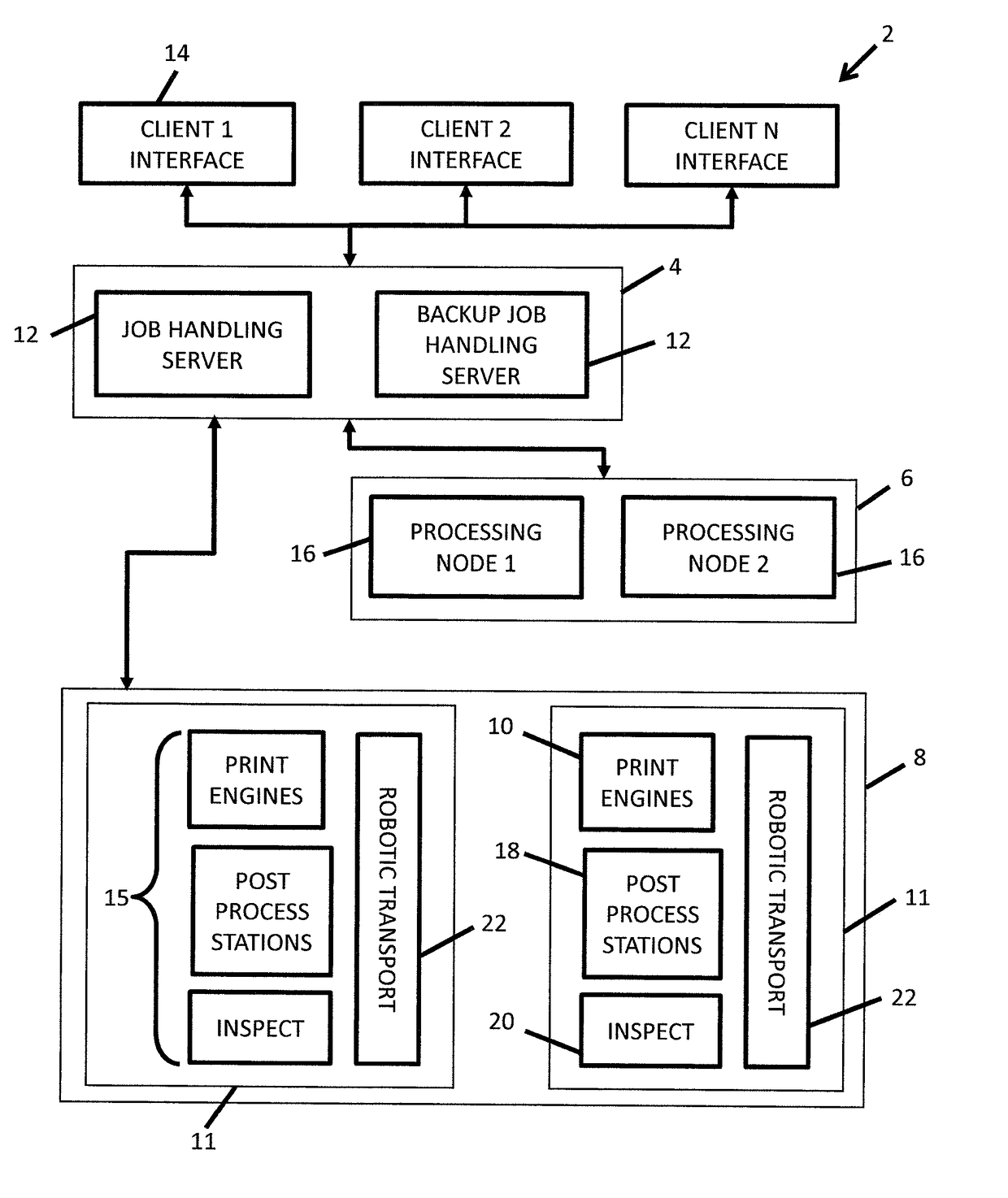

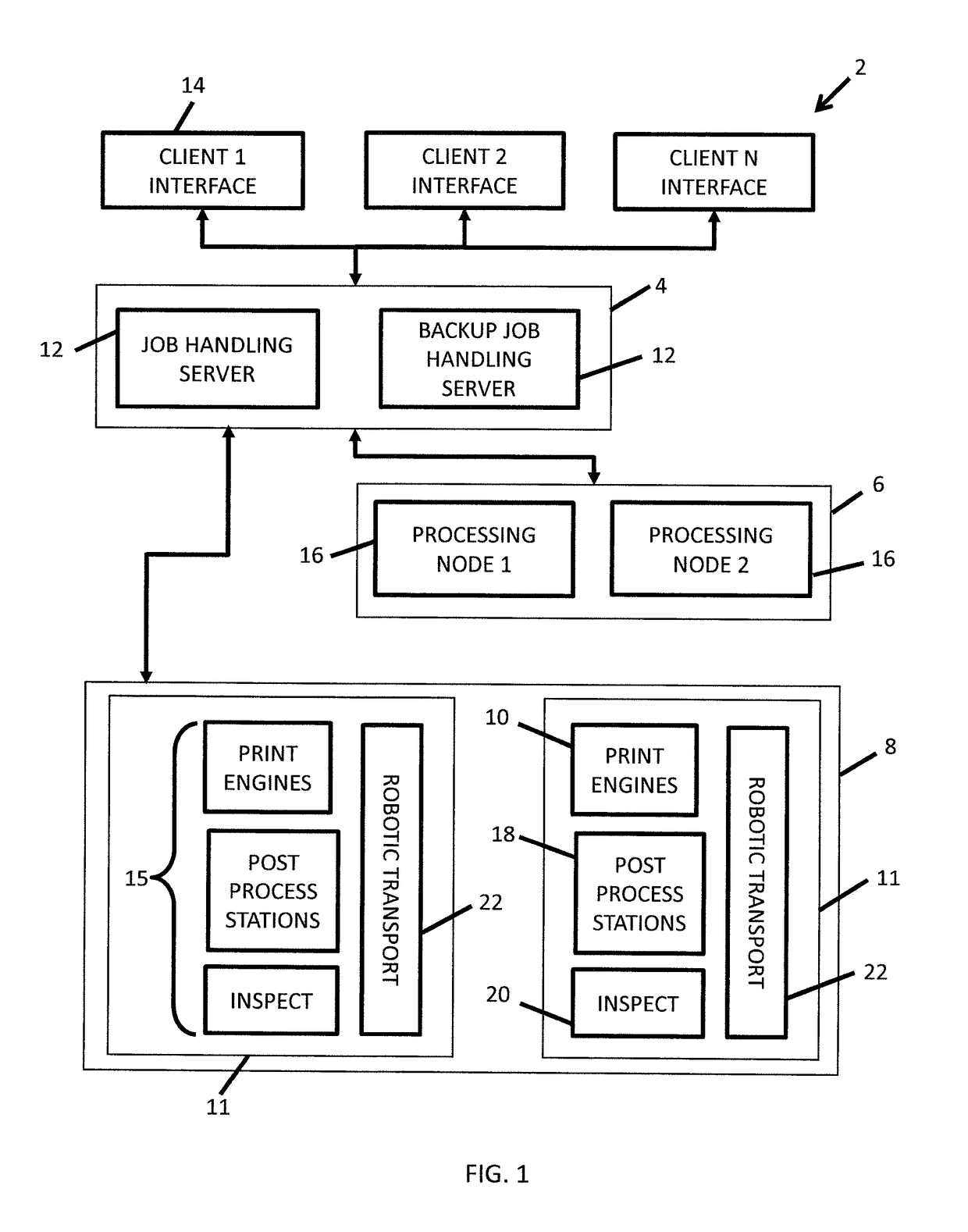

[0046]In step 76, processing tier 6 receives a properly proportioned virtual three dimensional body that was submitted to the client interface 14 as part of step 74. The processing tier 6 directly slices the virtual three dimensional body to provide the sequence of slice data arrays.

second embodiment

[0047]In step 76, the processing tier 6 receives or loads a virtual three dimensional body template that was previously stored in the printing system 2. The processing tier 6 utilizes dimensional parameters previously submitted to the client interface 14 to properly proportion and size the virtual three dimensional body template for the production job. Then the processing tier 6 directly slices the properly sized and proportioned virtual three dimensional body to provide the sequence of slice data arrays.

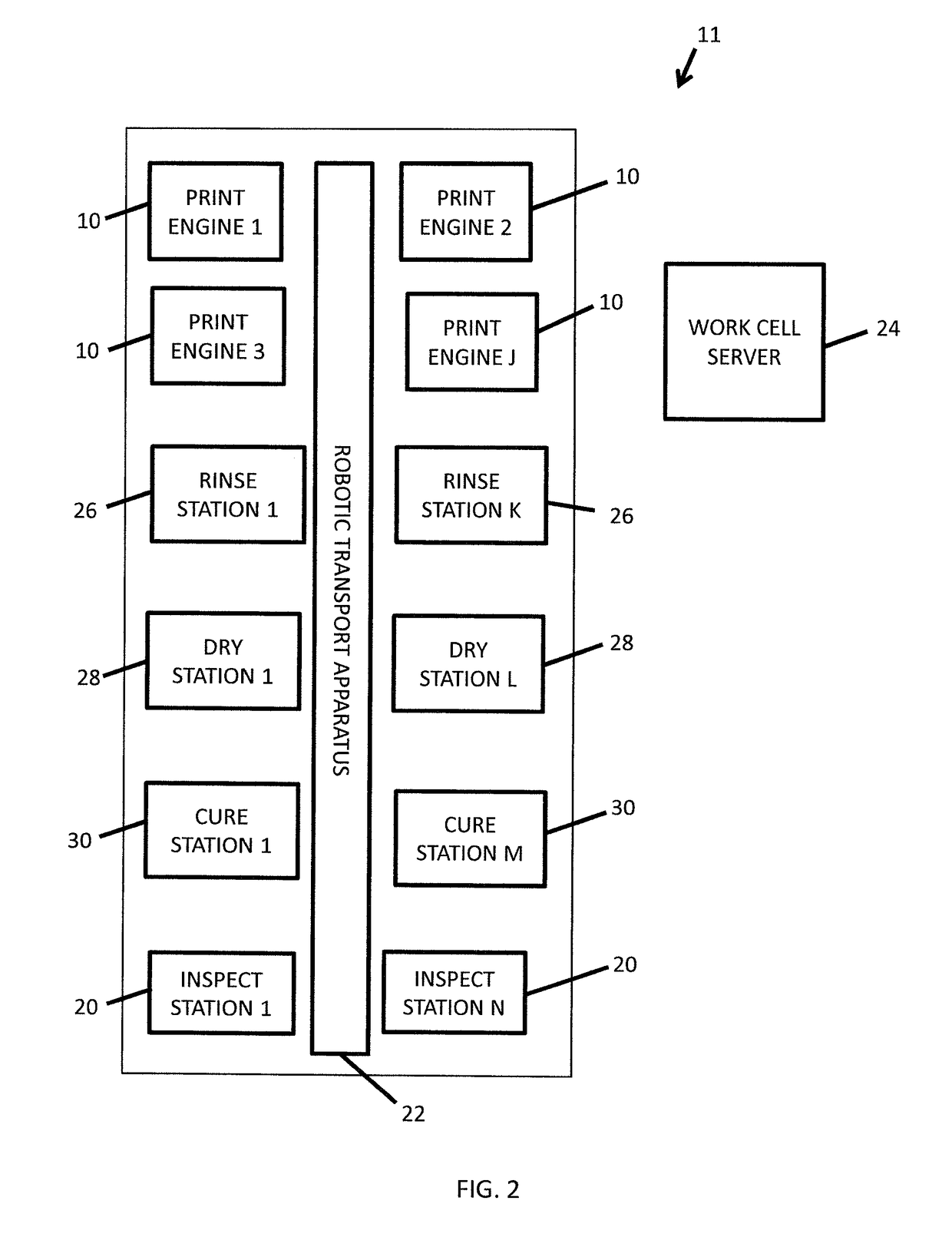

[0048]According to step 78, the slice data arrays are transferred from the processing tier 6 to the appliance tier 4. According to step 80, the appliance tier sends instructions and the sequence of slice data arrays to the work cell tier 8. The instructions are based on the process parameters received via the client interface 14. The instructions define sequences of functional cells 15 to be utilized to perform the submitted production job. As part of step 80, the appliance tier ide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com