Universal Anti-collision structure of safety helmet

a safety helmet and anticollision technology, applied in helmets, helmet covers, sport apparatus, etc., can solve the problems of increasing the number of assembling steps, affecting the comfort of helmet wearers, so as to enhance the comfort and snugness of wear, and enhance the structural strength of the entire assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

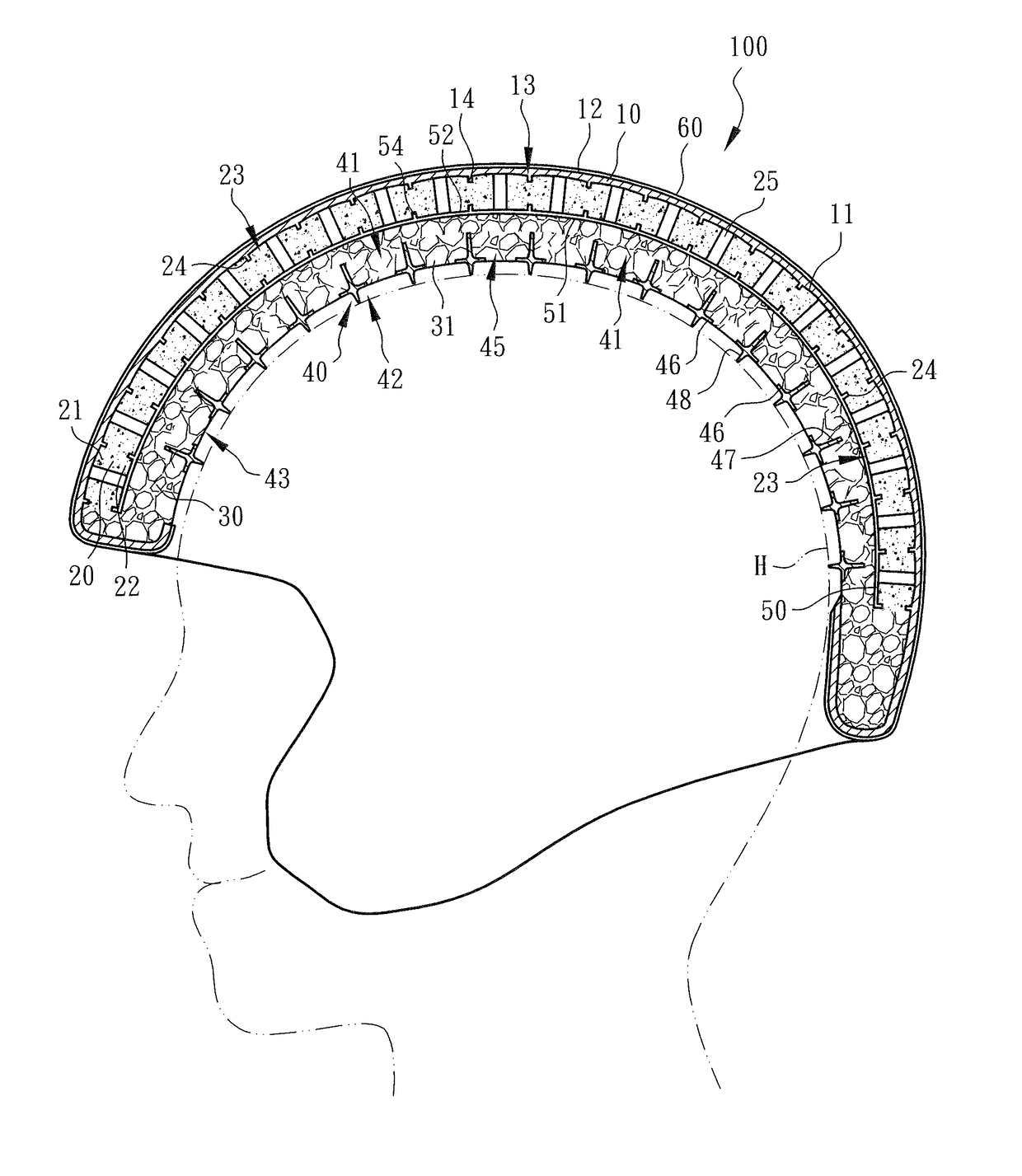

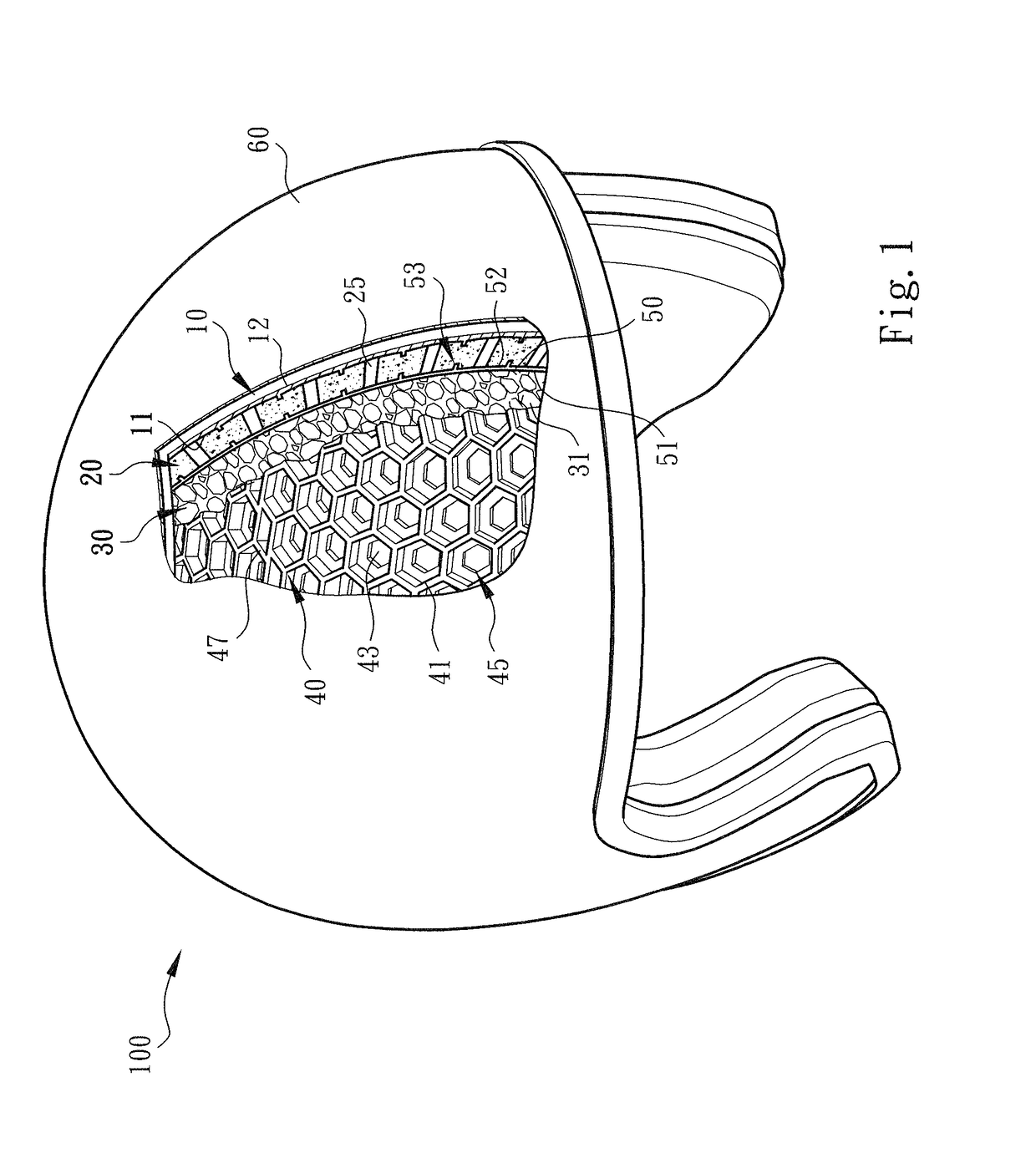

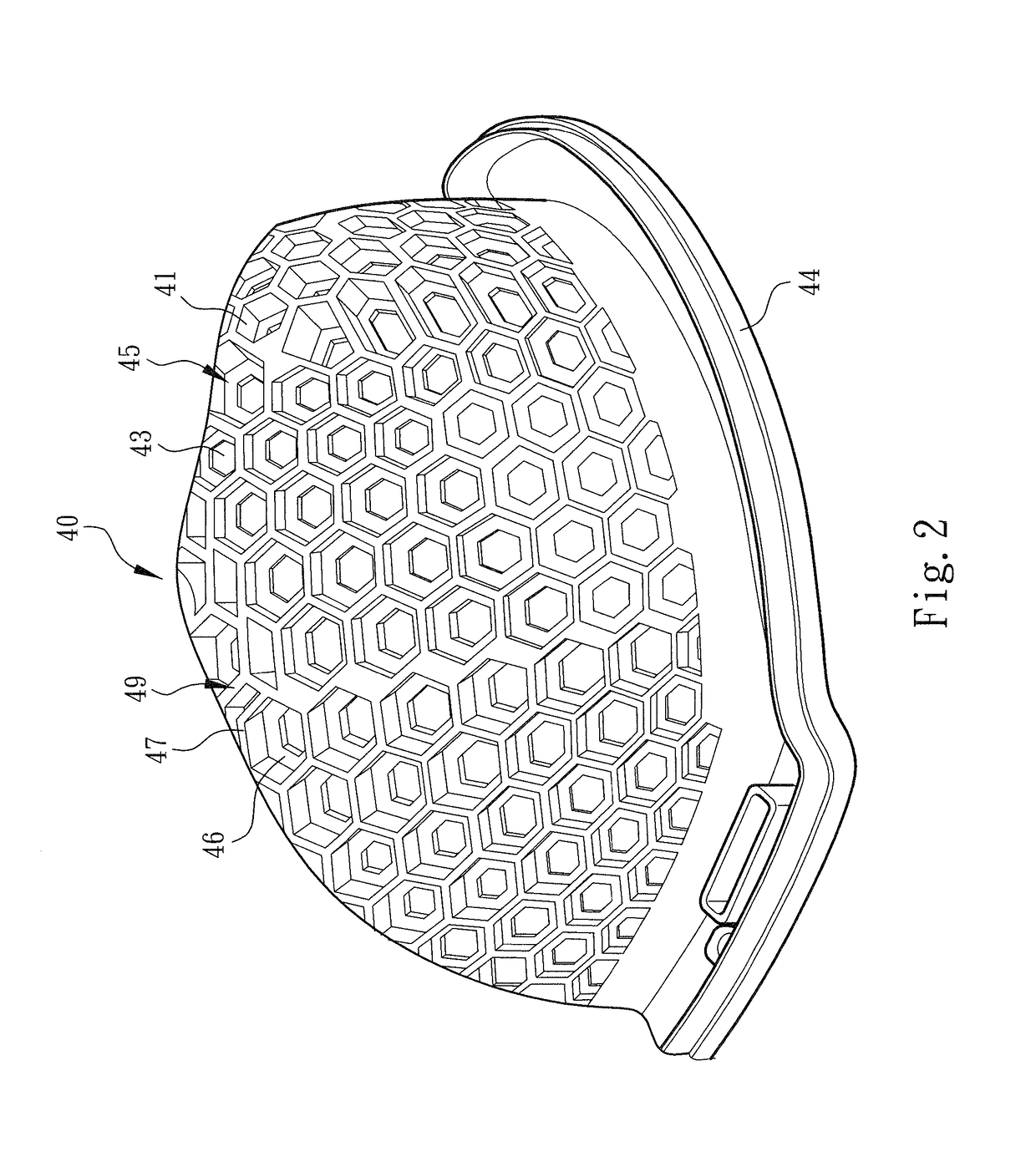

[0036]Please refer to FIGS. 1, 2 and 3. The universal anti-collision structure of safety helmet of the present invention is selectively exemplified with a safety helmet for sport wear. The safety helmet can be a football helmet, a hockey helmet, an engineering helmet, a mountaineering helmet, an equestrianism helmet, a bicycle helmet, a motorcycle helmet, a skiing helmet, a car racing helmet, etc. in a full face form or an open face form. The safety helmet includes a shell body 10, a filling body 30 enclosed in the shell body 10 and an elastic carrier body 40 enclosed in the shell body 10. The shell body 10, the filling body 30 and the elastic carrier body 40 are assembled with each other to form an assembly 100.

[0037]The upper section, upper side, lower section, lower side or bottom section mentioned hereinafter are referred to with the direction of the drawings as the reference direction. In addition, the part directed to the helmet wearer is defined as inner face or inner side, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com