Gas turbine blade assembly having retainer assembling structure, and gas turbine having same

a technology of assembling structure and gas turbine, which is applied in the direction of leakage prevention, engine fuction, machines/engines, etc., can solve the problems of difficult manufacture and installation, remarkably low work efficiency, and difficult disassembly process, etc., to achieve stable coupling structure, easy assembly and disassembly of retainers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

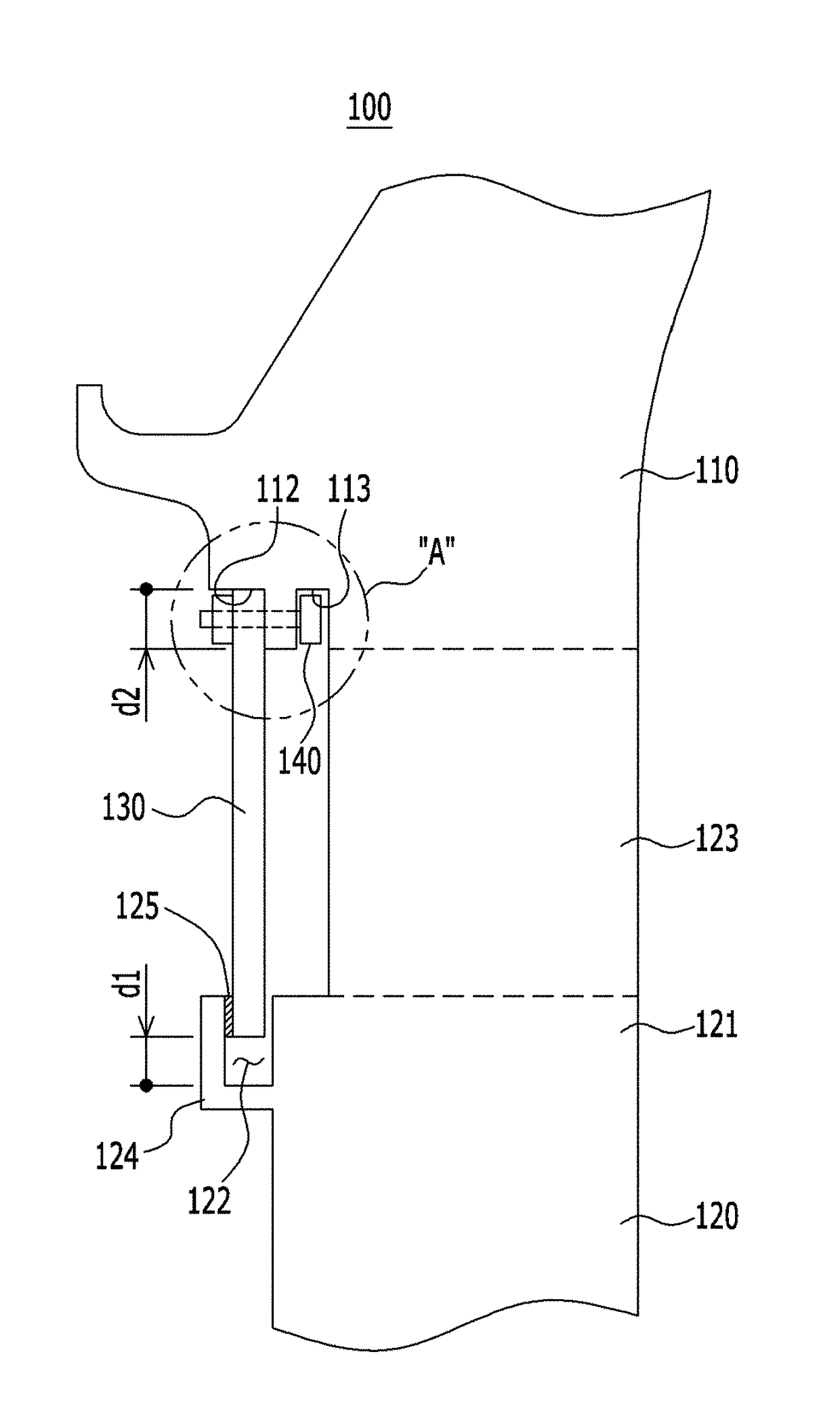

[0055]Reference will now be made in detail to preferred embodiments of the present disclosure with reference to the accompanying drawings. Before describing, it will be further understood that terms, such as those defined in commonly used dictionaries, should be interpreted as having a meaning that is consistent with their meaning in the context of the relevant art and the present disclosure, and will not be interpreted in an idealized or overly formal sense unless expressly so defined herein.

[0056]Throughout the specification, when a member is “on” another member, it includes not only when a member is in contact with another member, but also when there is another member between the two members. It will be further understood that the terms “comprise”, “include”, “have”, etc. when used in this specification, specify the presence of stated features, integers, steps, operations, elements, components, and / or combinations of them but do not preclude the presence or addition of one or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com