Ultralight Photovoltaic Power Generation Tiles

a photovoltaic power generation and ultralight technology, applied in the field of space-based solar power stations, can solve the problems of reducing the economic viability of such sbsp systems, increasing the collection rate of solar energy, and reducing the size of sbsp systems to generate sufficient electrical power, etc., to achieve the effect of improving thermal emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

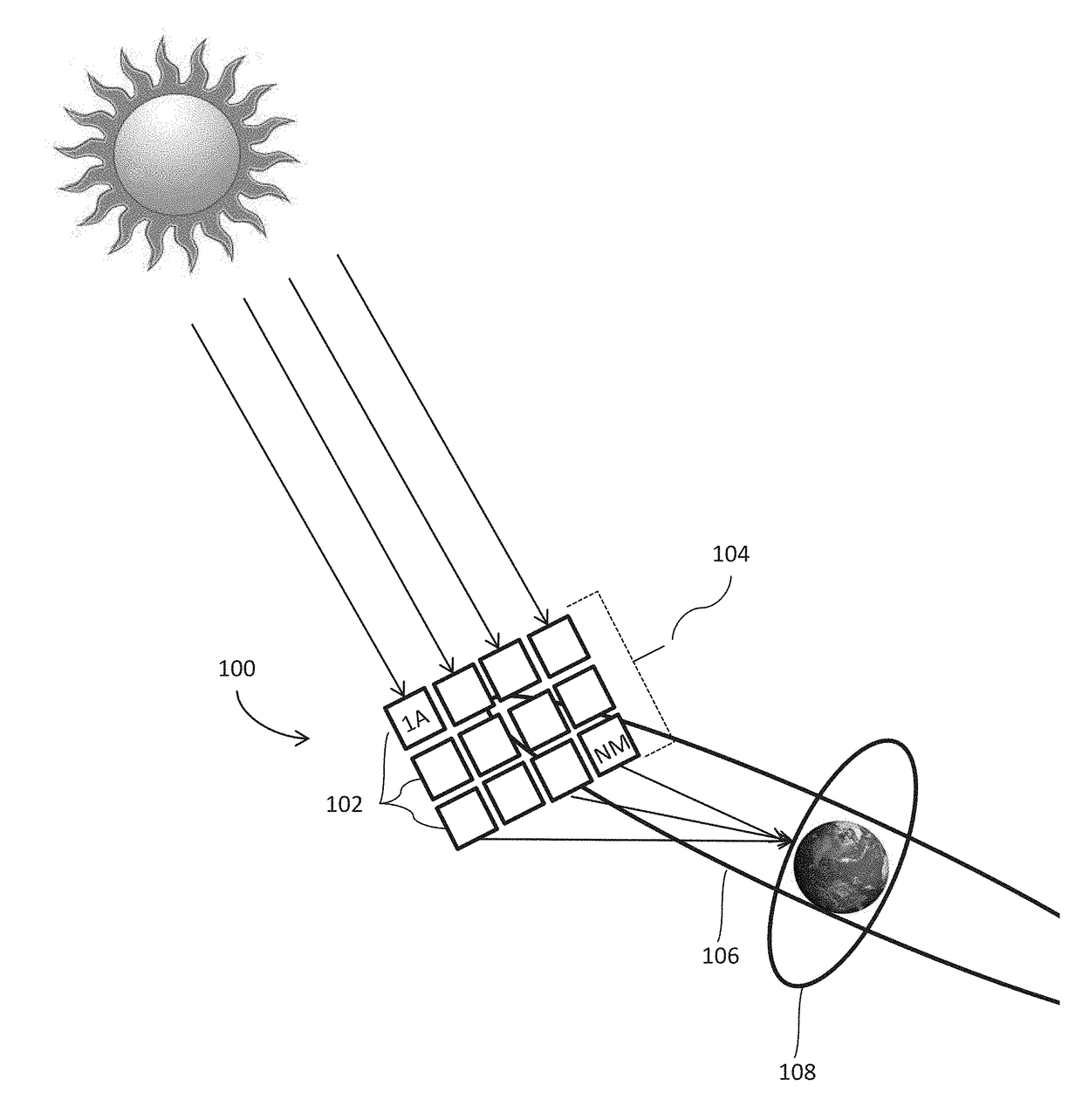

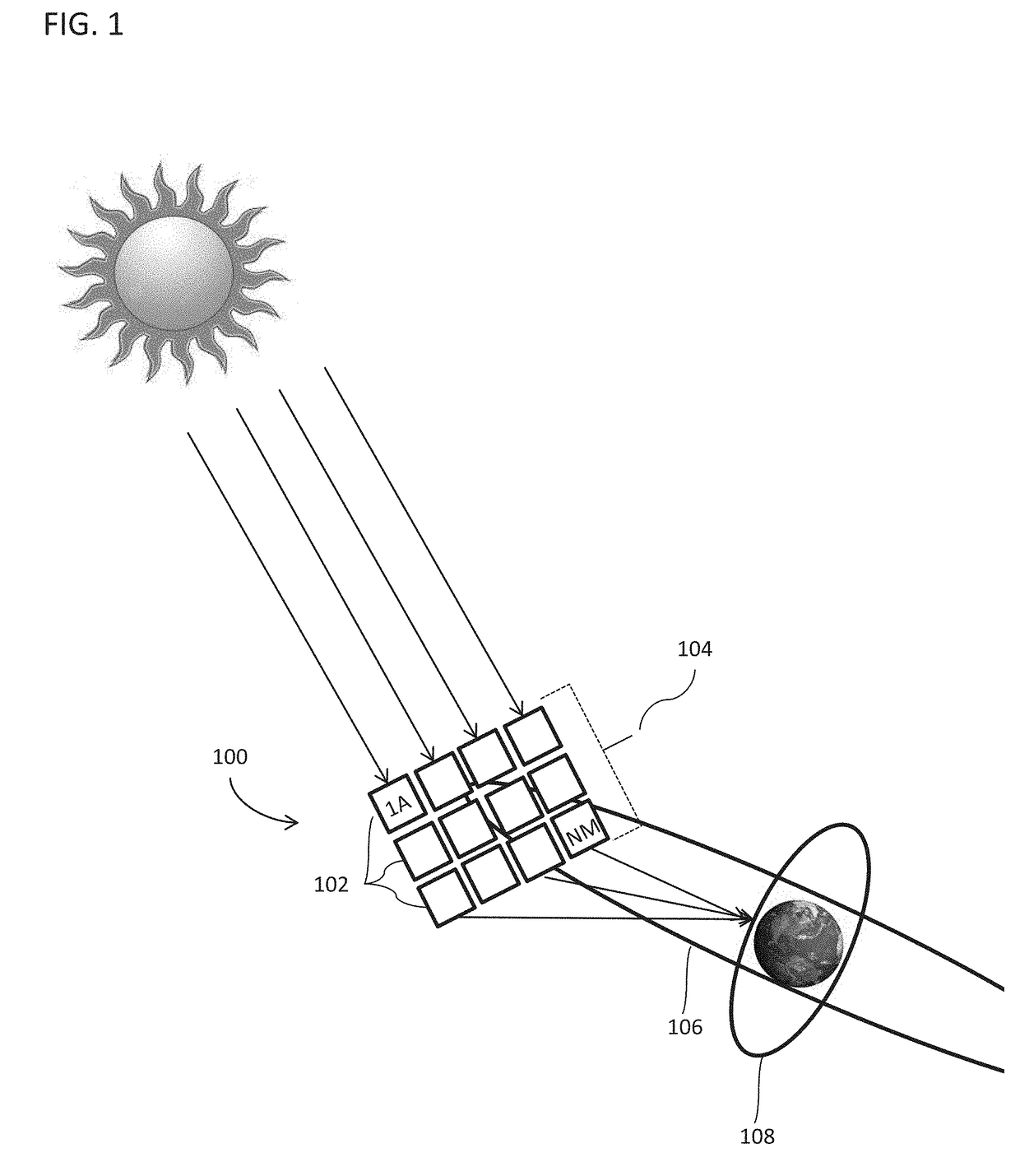

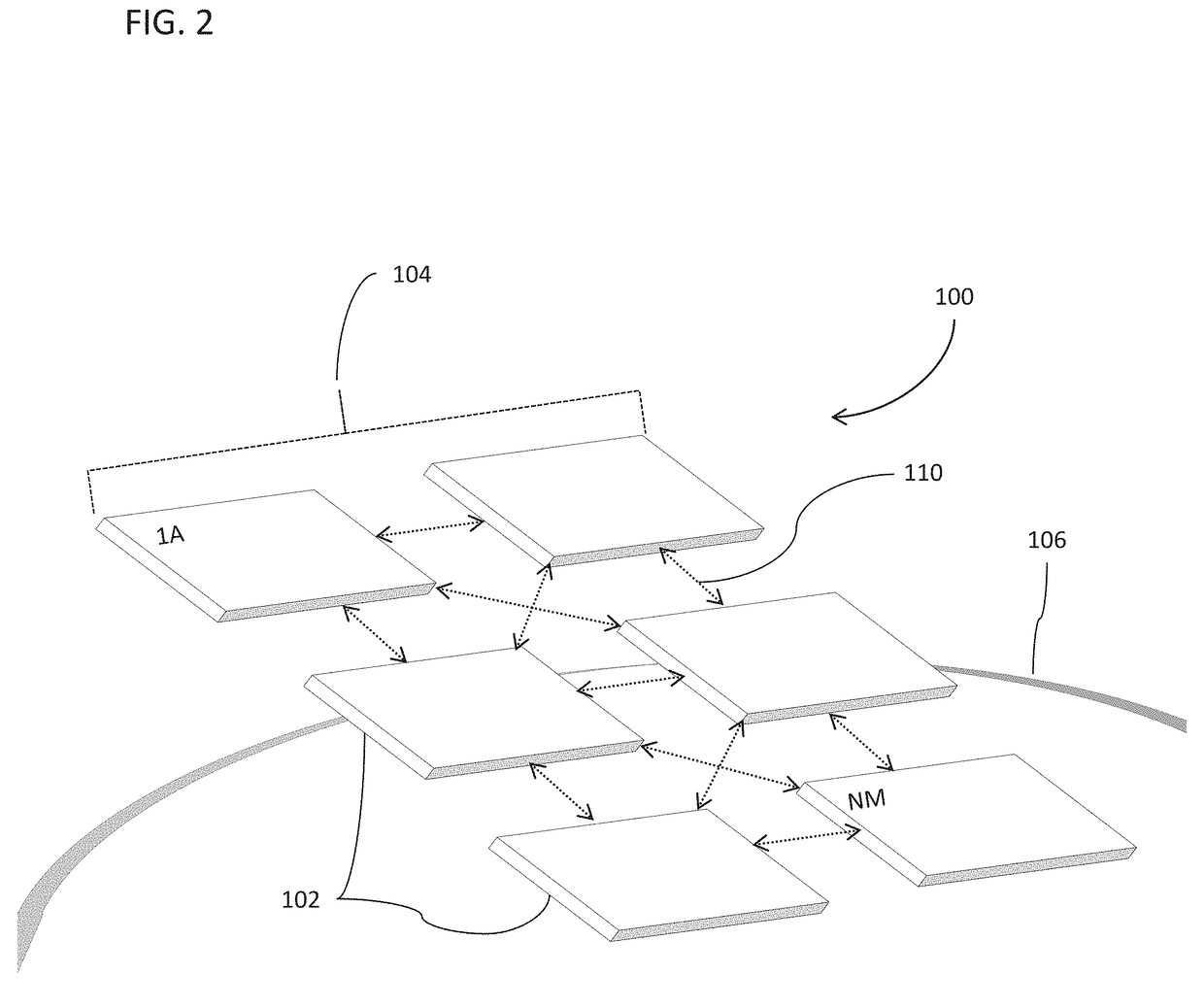

[0085]Turning now to the drawings, large-scale space-based solar power (SBSP) stations and efficient power generation tiles in accordance with various embodiments of the invention are illustrated. In many embodiments, the SBSP systems include arrays of independent satellite modules each incorporating arrays of independent solar electric power generation tiles. In several embodiments, the power generation tiles are each formed incorporating independent photovoltaic cells, power transmitters, and control circuits. The satellite modules and power generation tiles may be formed from compactible structures according to some embodiments. Methods for deploying, stabilizing, operating and constructing such large-scale space-based solar power systems in accordance with a number of embodiments of the invention are also described. Similar systems and methods are described in: U.S. provisional patent application Ser. No. 61 / 993,016 entitled “Large-Scale Space-Based Array: Packaging, Deployment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com