Oil Tanker

a technology for oil tankers and oil tanks, applied in waterborne vessels, passenger handling devices, ship accessories, etc., can solve the problems of obstructing the effective use, requiring a large amount of money for maintenance and inspection work, and easy corrosion, so as to reduce marine pollution, facilitate crew passage, and use the effect of the upper area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Hereinafter, embodiments of the present invention will be described with reference to the drawings.

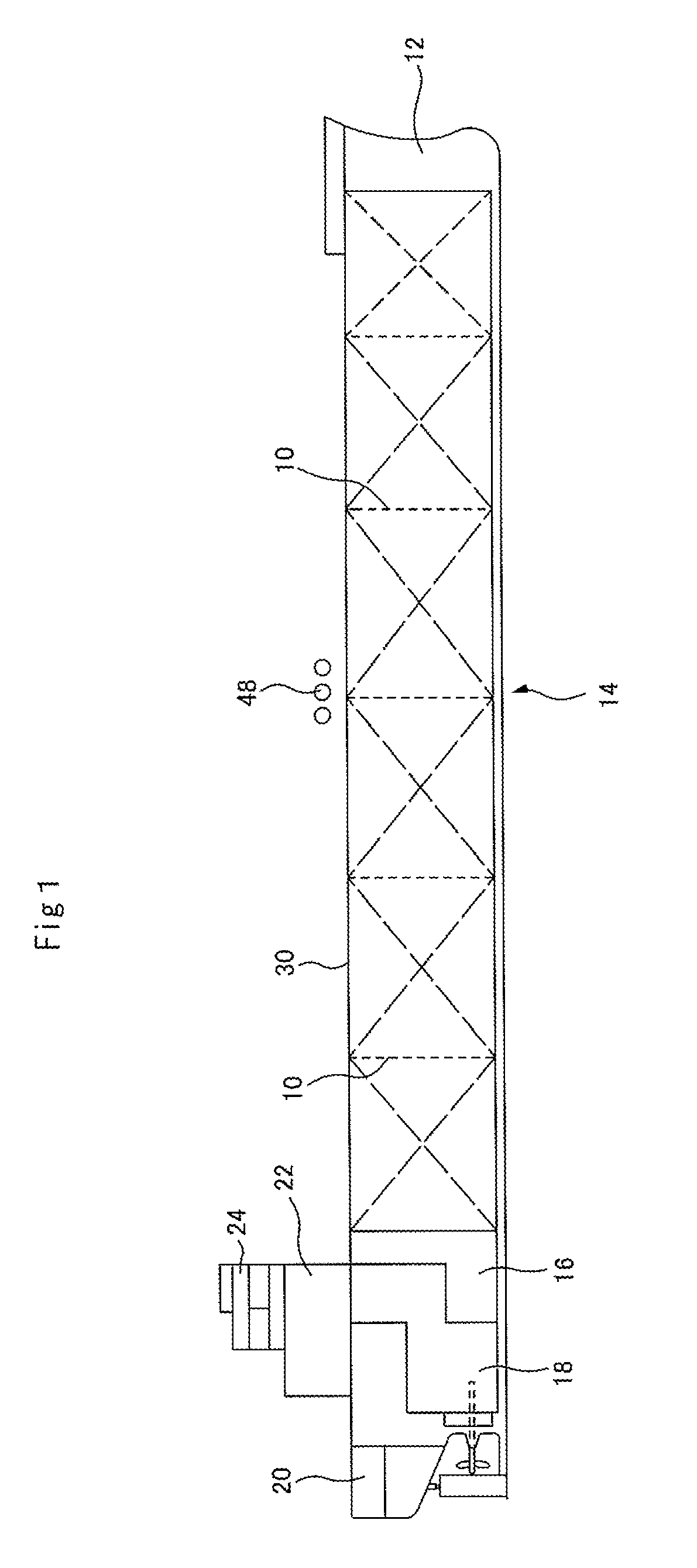

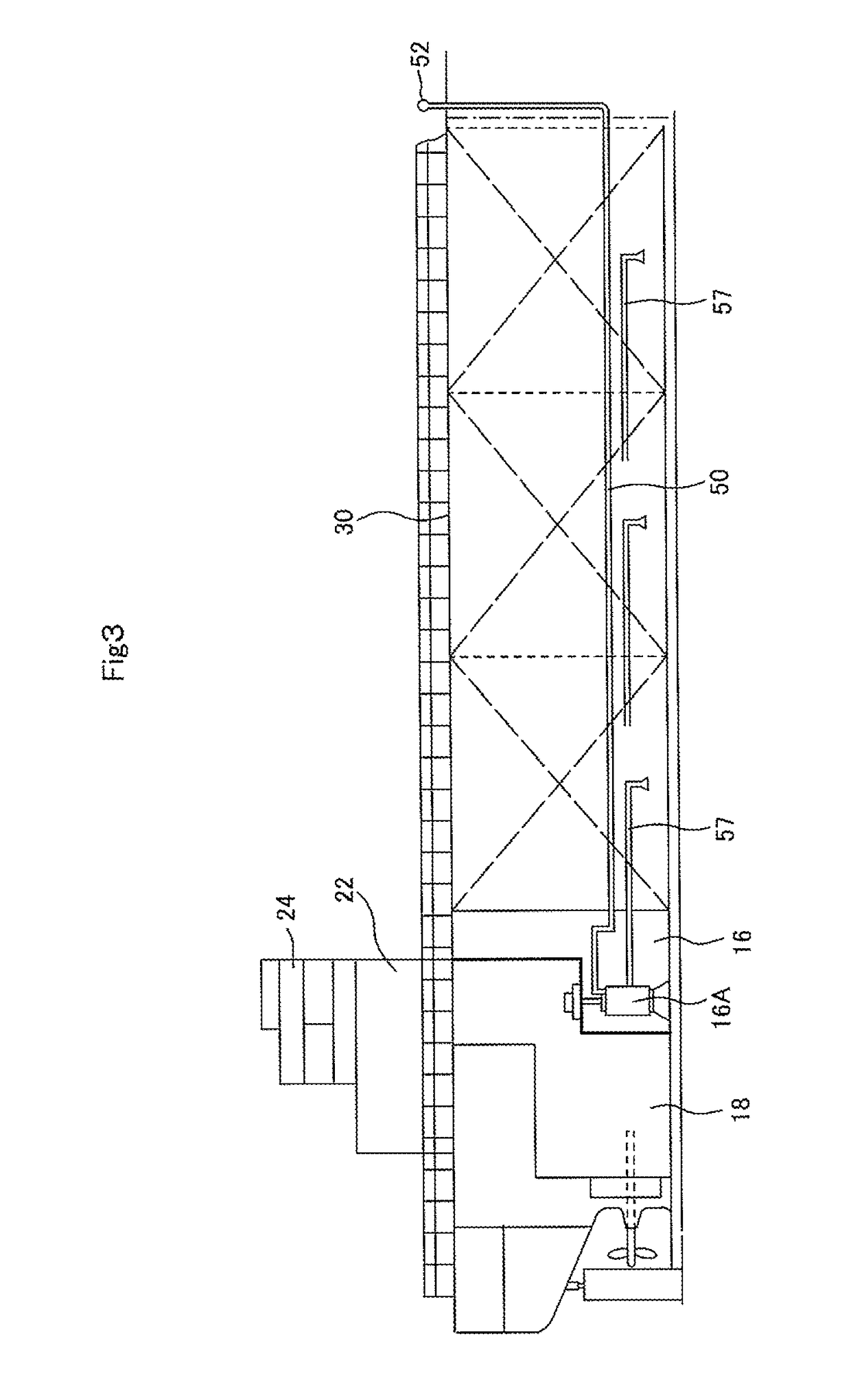

[0020]First, a dedicated oil tanker carrying only crude oil will be described. As shown in FIG. 1 and FIG. 2, a hull is partitioned by transverse bulkheads 10 and a bow portion 12, a cargo tank area 14, a pump room 16, an engine room 18, and a stern portion 20 are arranged in this order. An accommodation area 22 and a wheelhouse 24 are located above the engine room 18.

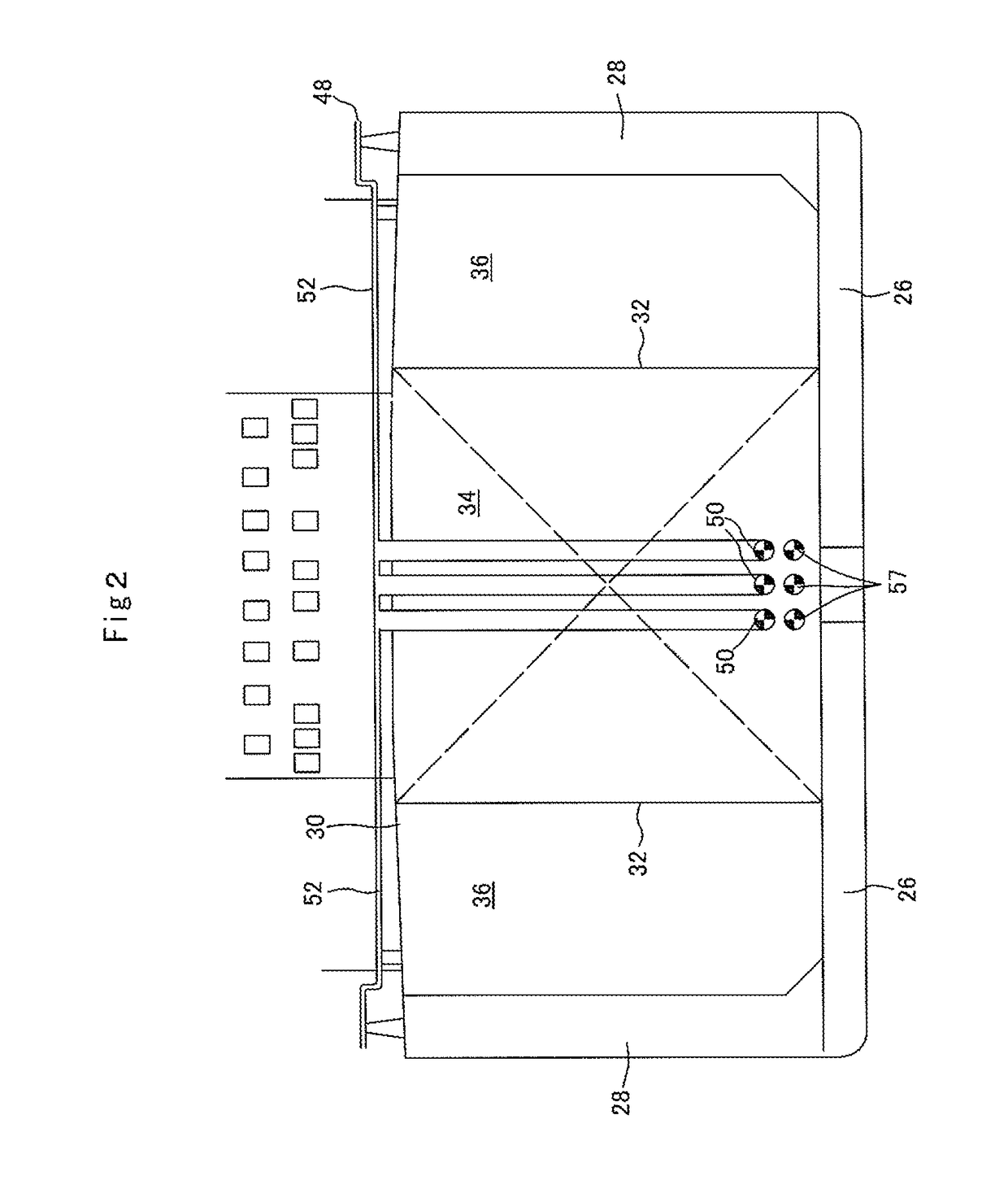

[0021]The cargo tank area 14, as shown in FIG. 2, has both of the bottom and the side of the ship constructed of a double hull structure and their interiors are constructed of ballast tanks 26, 28, respectively. A space surrounded by the double hull structure and an upper deck 30 is partitioned into a center cargo tank 34 and left and right cargo tanks 36 by longitudinal bulkheads 32 extended longitudinally on the left and right sides.

[0022]According to the present invention, there is provided a cargo oil delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com