A kind of anti-pollution buoyancy liquid container and its application

A container and buoyancy technology, which is applied in the field of anti-pollution buoyancy liquid containers, can solve problems such as economic loss, environmental pollution, and liquid bag environmental pollution, and achieve the effects of avoiding secondary leakage, reducing marine pollution, and convenient and fast transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

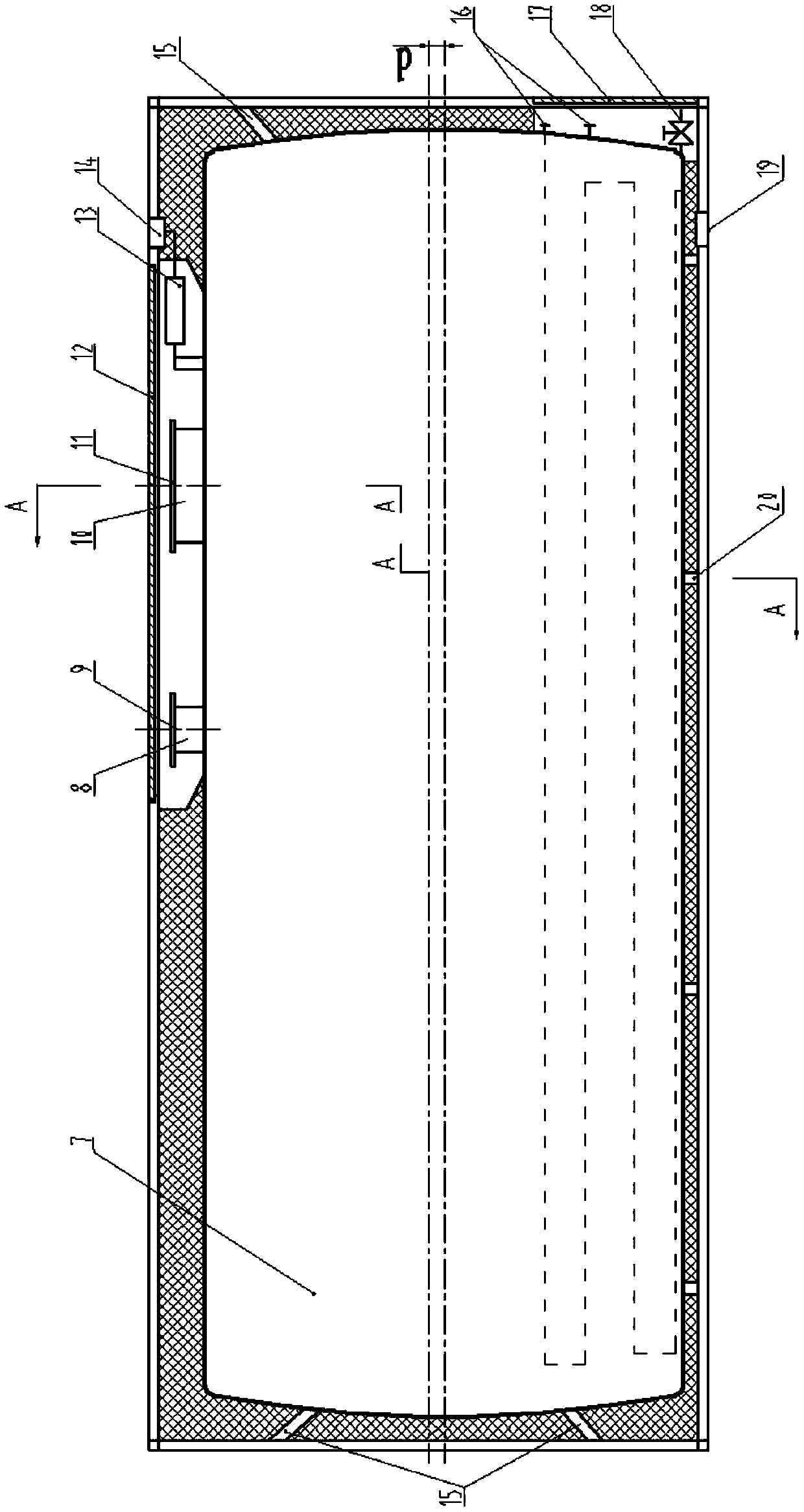

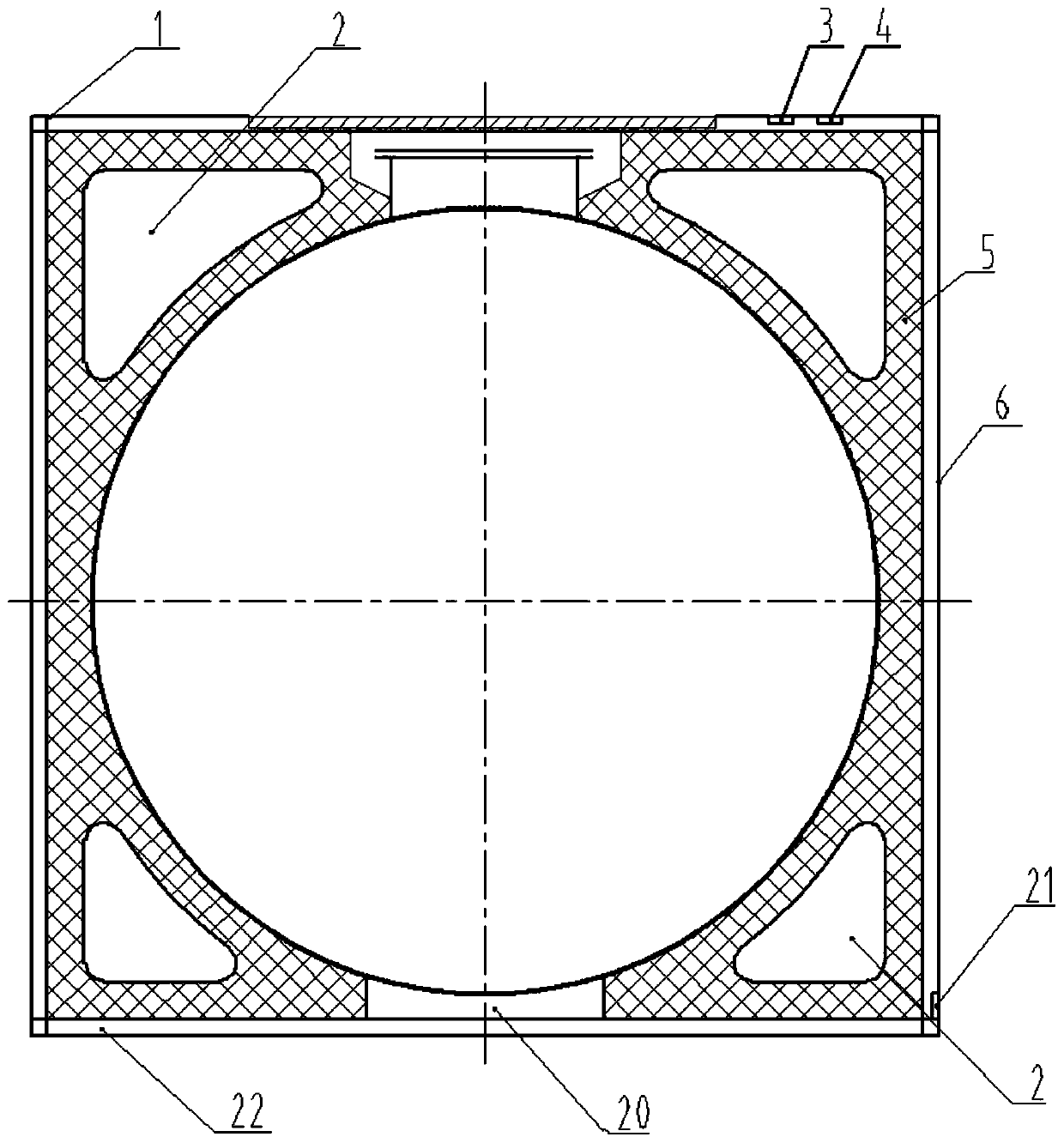

[0041] like Figure 1-Figure 2 As shown, a kind of anti-pollution buoyancy liquid container related to the present invention includes a sealed box body 1 with a cuboid shape for container transportation. The sealed box body 1 is a support structure 22 welded by steel beams and a fixed The sealing steel plate 6 outside the support structure 22 is welded, and the sealing steel plate 6 is a profiled plate with continuous rectangular corrugations on the surface. A feed bin door 12 that opens flat upwards and can be sealed and locked is installed on the top surface of the sealed box body 1 , and a discharge bin door 17 that opens flat outwards and can be sealed and locked is installed on the lower part of one end of the sealed box body 1 .

[0042]In the sealed box 1, a cylindrical container tank 7 with both ends closed is fixed through the support of the bottom support 20 and the end surface support 15. The container tank 7 is arranged horizontally, and its central axis is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com