Deep-sea hydraulic pressure type hydraulic drive system

A driving system and water pressure technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of unsustainability, limited power, poor low temperature discharge performance, etc., to reduce marine pollution problems, reduce Volume and weight, the effect of sufficient driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

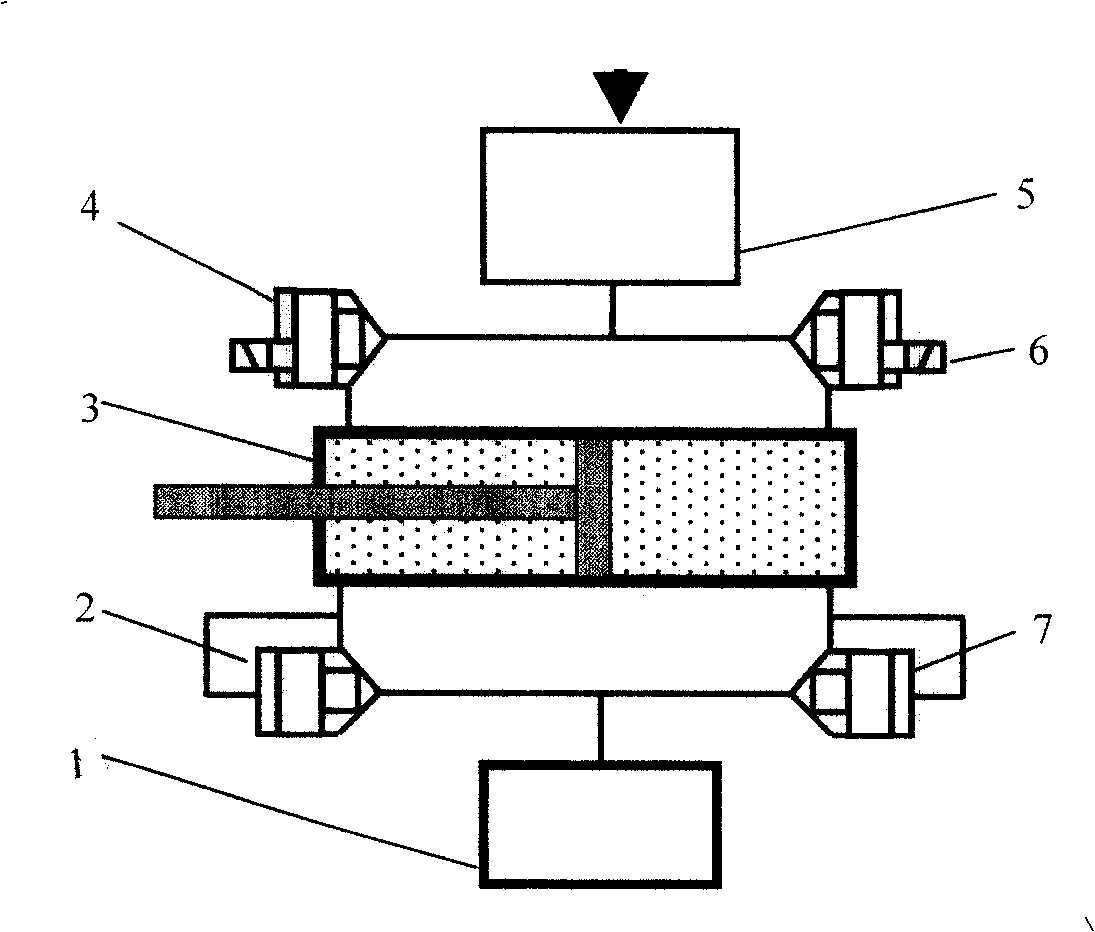

[0012] like figure 1 As shown, 1 in the figure is a pressure-resistant container, 2 and 7 are high-speed one-way valves, 3 is a hydraulic cylinder, 4 and 6 are high-speed switching valves, and 5 is a seawater pressure flow control valve block. Among them, the seawater pressure flow control valve block 5 is arranged on the top of the entire hydraulic system, and the seawater pressure flow control valve block 5 communicates with the hydraulic cylinder 3 through the high-speed switching valves 4 and 6: the high-speed switching valves 4 and 6 are respectively set on the top of the hydraulic cylinder 3 , and communicate with the cavities on the left and right sides of the hydraulic cylinder 3; the hydraulic cylinder 3 communicates with the pressure-resistant container 1 arranged at the bottom of the hydraulic drive system through the high-speed check valves 2 and 7: the high-speed check valves 2 and 7 are respectively set It is at the bottom of the hydraulic cylinder 3 and communic...

Embodiment 2

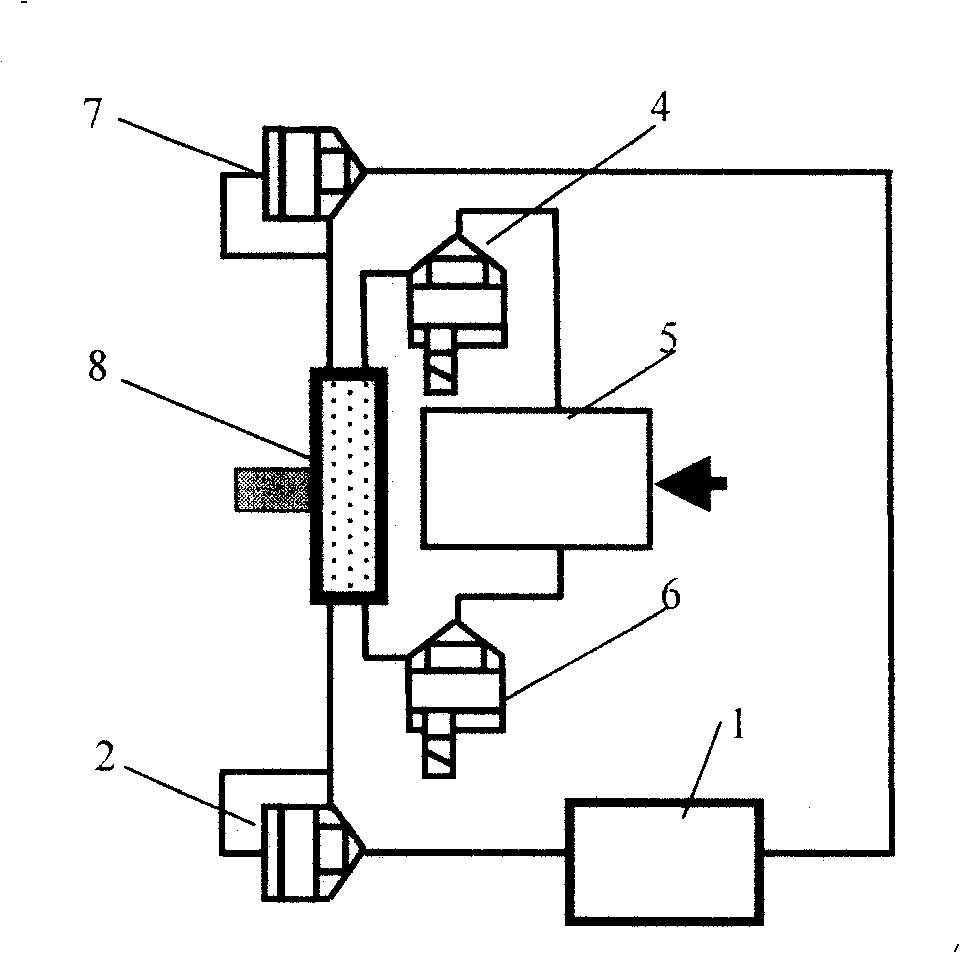

[0018] like figure 2 As shown, the seawater pressure flow control valve block 5 communicates with the hydraulic motor 8 through the high-speed switch valves 4 and 6 , and the hydraulic motor communicates with the pressure-resistant container 1 through the high-speed one-way valves 2 and 7 . Among them, the high-speed on-off valve 4 and the high-speed one-way valve 7 are arranged on one side of the hydraulic motor 8, and communicate with a pair of water inlet and outlet ports on the hydraulic motor 8, and the high-speed on-off valve 6 and the high-speed one-way valve 2 are correspondingly arranged on the hydraulic motor 8. The other side of the hydraulic motor 8 communicates with another pair of water inlet and outlet. The input ends of the high-speed switching valves 4 and 6 are connected to the seawater pressure flow control valve block 5, and the output ends are respectively connected to the two water inlets of the hydraulic motor 8; the input ends of the high-speed check v...

Embodiment 3

[0024] In Embodiment 2, a generator set can be installed coaxially with the hydraulic motor, and the hydraulic motor can be driven to generate electricity while utilizing the pressure of deep sea water to drive the coaxial generator set to generate power in deep sea. The electrical energy that the hydraulic drive system can provide is related to the volume of the pressure vessel, the larger the volume, the greater the electrical energy it can provide. Therefore, the volume of the pressure vessel can be designed according to the actual deep sea operation time. The hydraulic drive system can provide sufficient power resources for the short-term work of the deep-sea resource development operation device, or the deep-sea resource detection device that stays on the seabed for a long time.

[0025] Others are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com