Gas supply device and method for starting operation of gas supply device

a gas supply device and gas supply technology, applied in the direction of electrochemical generators, container discharging methods, container filling under pressure, etc., can solve the problem of prolonged activation time, and achieve the effect of reducing the time required for activation of gas stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

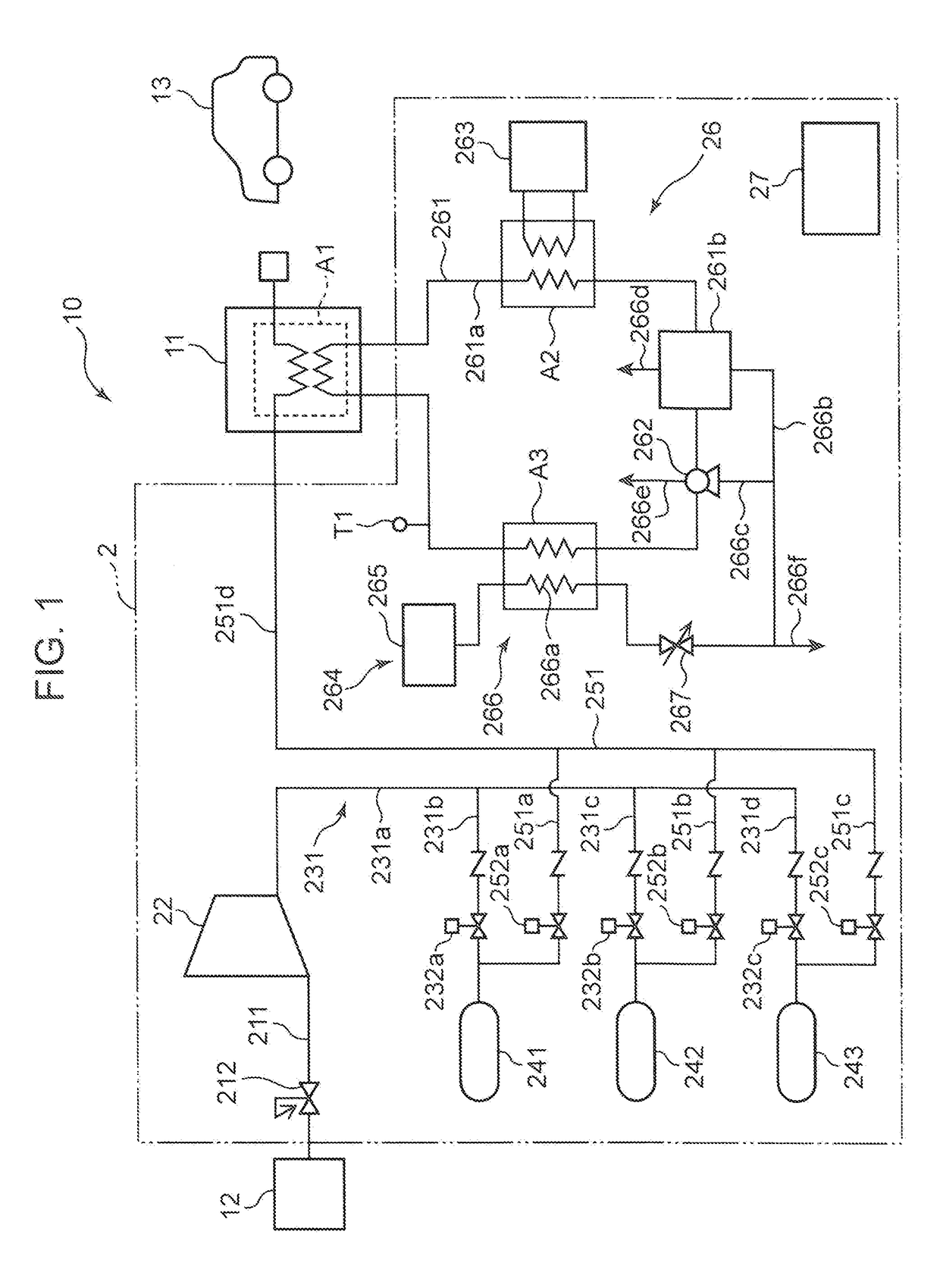

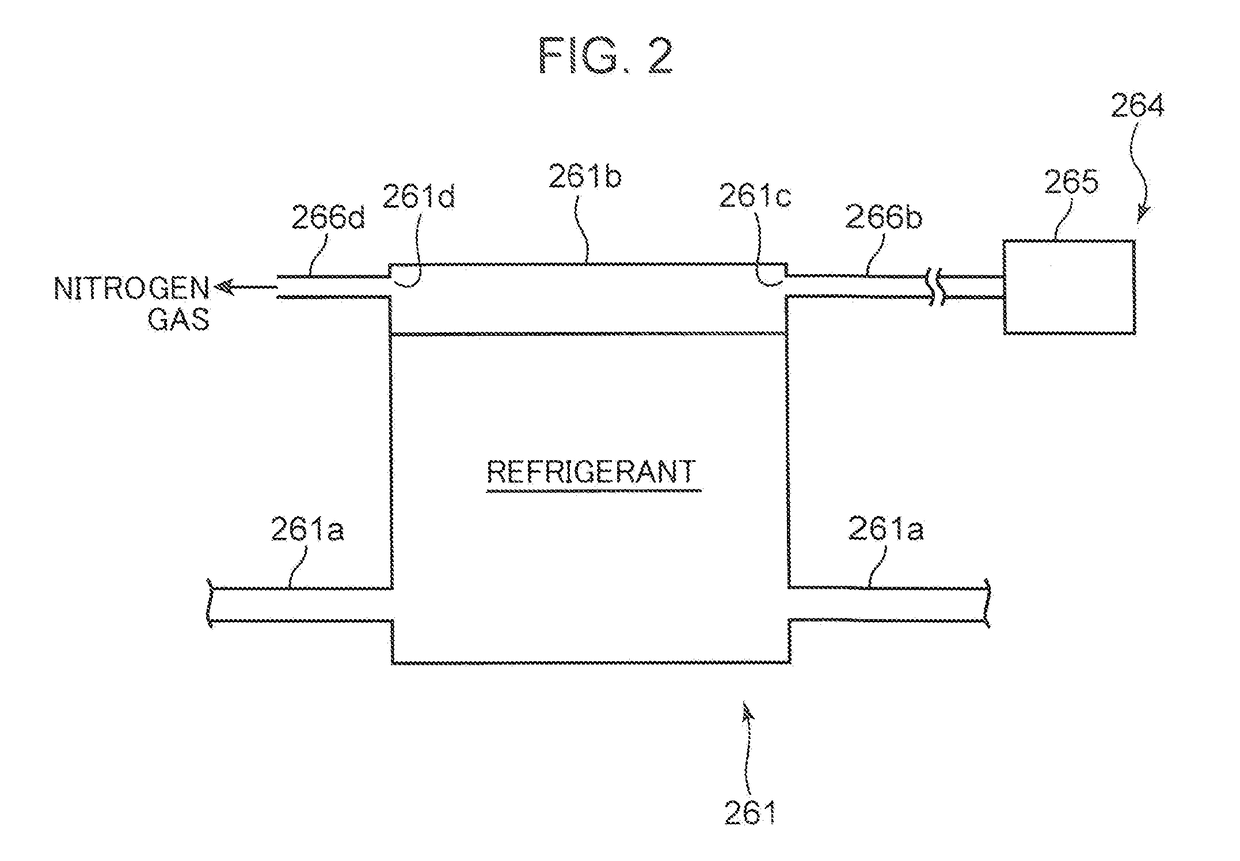

[0017]FIG. 1 is a diagram schematically illustrating a configuration of a hydrogen station 10 according to a first embodiment of the present invention. The hydrogen station 10 includes a gas supply device 2 and a dispenser 11, which is a charging facility.

[0018]The gas supply device 2 compresses a hydrogen gas to generate a compressed gas, and supplies the compressed gas to the dispenser 11. In the present embodiment, as illustrated in FIG. 1, the hydrogen gas produced in a gas production device 12 is supplied to the gas supply device 2, and the gas supply device 2 compresses the hydrogen gas to generate the compressed gas.

[0019]Note that a supply source for supplying the hydrogen gas to the gas supply device 2 may not be the gas production device 12. For example, the hydrogen gas may be supplied from a tank member storing the hydrogen gas to the gas supply device 2.

[0020]In the present embodiment, since the gas supply device 2 is a component of the hydrogen station 10, the gas prod...

second embodiment

[0074]Next, a gas supply device 2 according to a second embodiment will be described with reference to FIG. 4. Note that the present embodiment will describe only portions different from the first embodiment, and descriptions of the same structure, operation, and effect as those of the first embodiment will be omitted.

[0075]In the second embodiment, a configuration of a hydrogen station 10 is similar to the configuration of the hydrogen station 10 of the first embodiment, but the second embodiment is different from the first embodiment in a method for operating the hydrogen station 10.

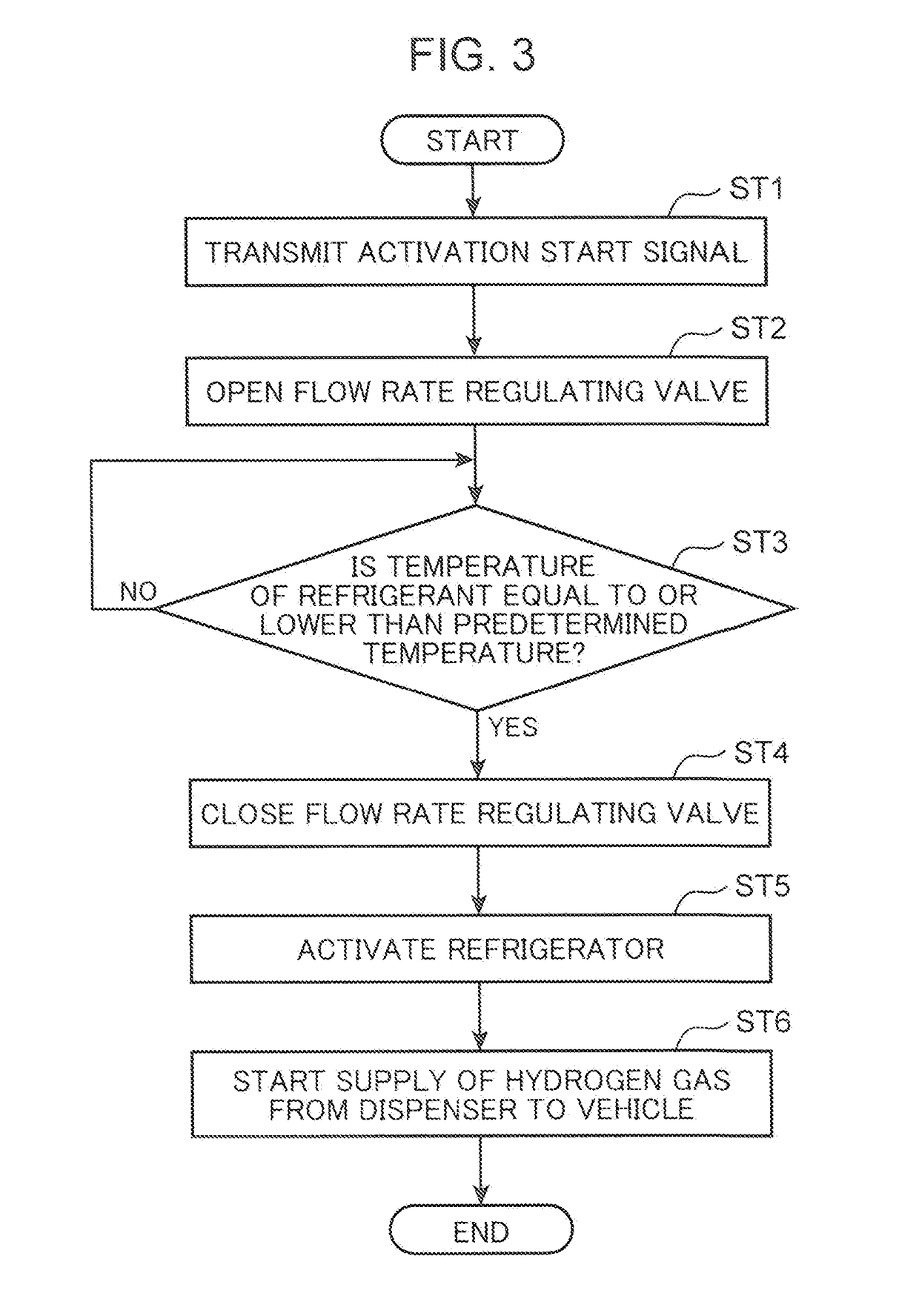

[0076]In the second embodiment, as illustrated in FIG. 4, upon receipt of an activation start signal transmitted in step ST1, while opening a flow rate regulating valve 267 (step ST2), a control unit 27 performs control to activate a refrigerator 263 (step ST5). Accordingly, a refrigerant flowing through a refrigerant flow path 261 is cooled by the refrigerator 263 and is also cooled by latent heat of ...

third embodiment

[0082]Next, a gas supply device 2 according to a third embodiment will be described with reference to FIGS. 5 and 6. Note that the present embodiment will describe only portions different from the first embodiment, and descriptions of the same structure, operation, and effect as those of the first embodiment will be omitted.

[0083]In the third embodiment, a structure of a cooling device 264 is different from a configuration of a cooling device 264 in the first embodiment.

[0084]In the third embodiment, the cooling device 264 includes a liquefied gas tank 265, a liquefied gas flow path 268, and a flow rate regulating valve 267. The liquefied gas flow path 268 introduces liquid nitrogen stored in the liquefied gas tank 265 into a refrigerant tank 261b to cool a refrigerant in the refrigerant tank 261b.

[0085]Specifically, as illustrated in FIGS. 5 and 6, the liquefied gas flow path 268 includes an introduction side flow path 268a, an intra-tank flow path 268b, and a lead-out side flow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com