Liquid cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

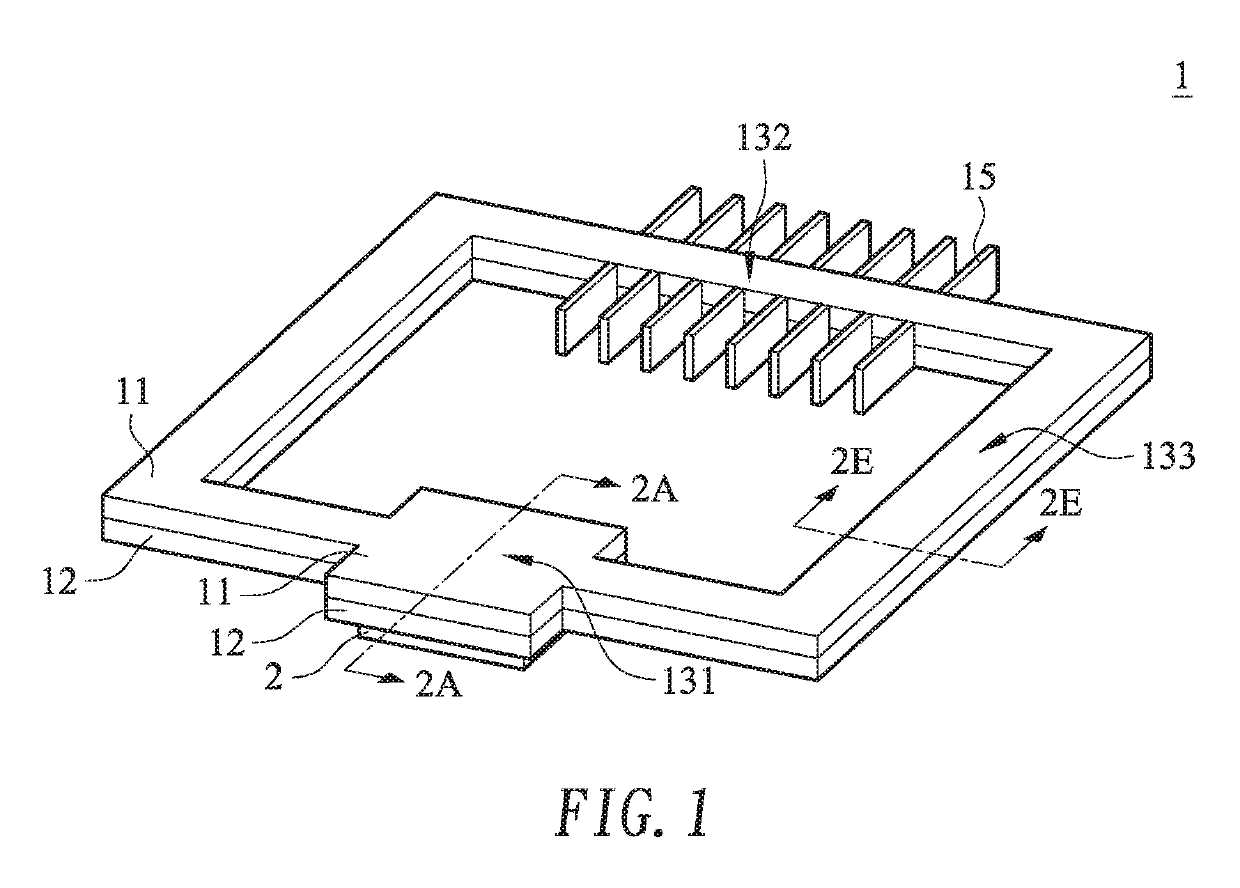

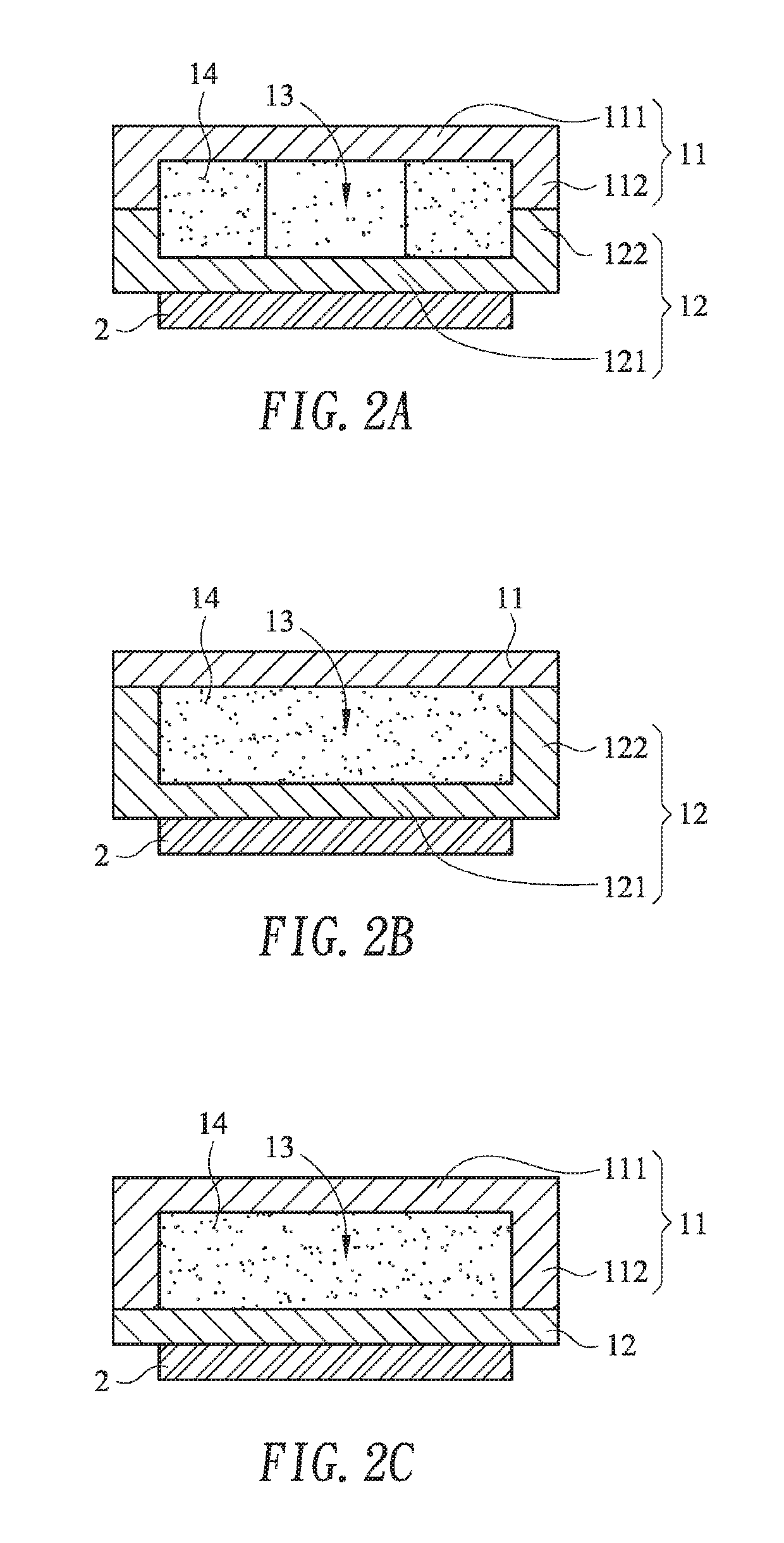

[0035]FIG. 1 is a schematic perspective view illustrating a liquid cooling device according to the present invention. FIG. 2A is a schematic cross-sectional view illustrating a heat-absorbing section of the liquid cooling device of FIG. 1 and taken along the line 2A-2A. As shown in FIGS. 1 and 2A, the liquid cooling device 1 comprises an upper plate 11 and a lower plate 12. The upper plate 11 and the lower plate 12 are combined together to define a chamber 13. A liquid working medium 14 is accommodated within the chamber 13. The chamber 13 comprises a heat-absorbing section 131, a heat-radiating section 132 and a driving section 133. The function of the heat-absorbing section 131 is similar to the function of a liquid cooling head. When the heat-absorbing section 131 is in thermal contact with a heat generation element 2, the heat from the heat generation element 2 is absorbed by the heat-absorbing section 131 and transferred to the liquid working medium 14. Consequently, the temper...

second embodiment

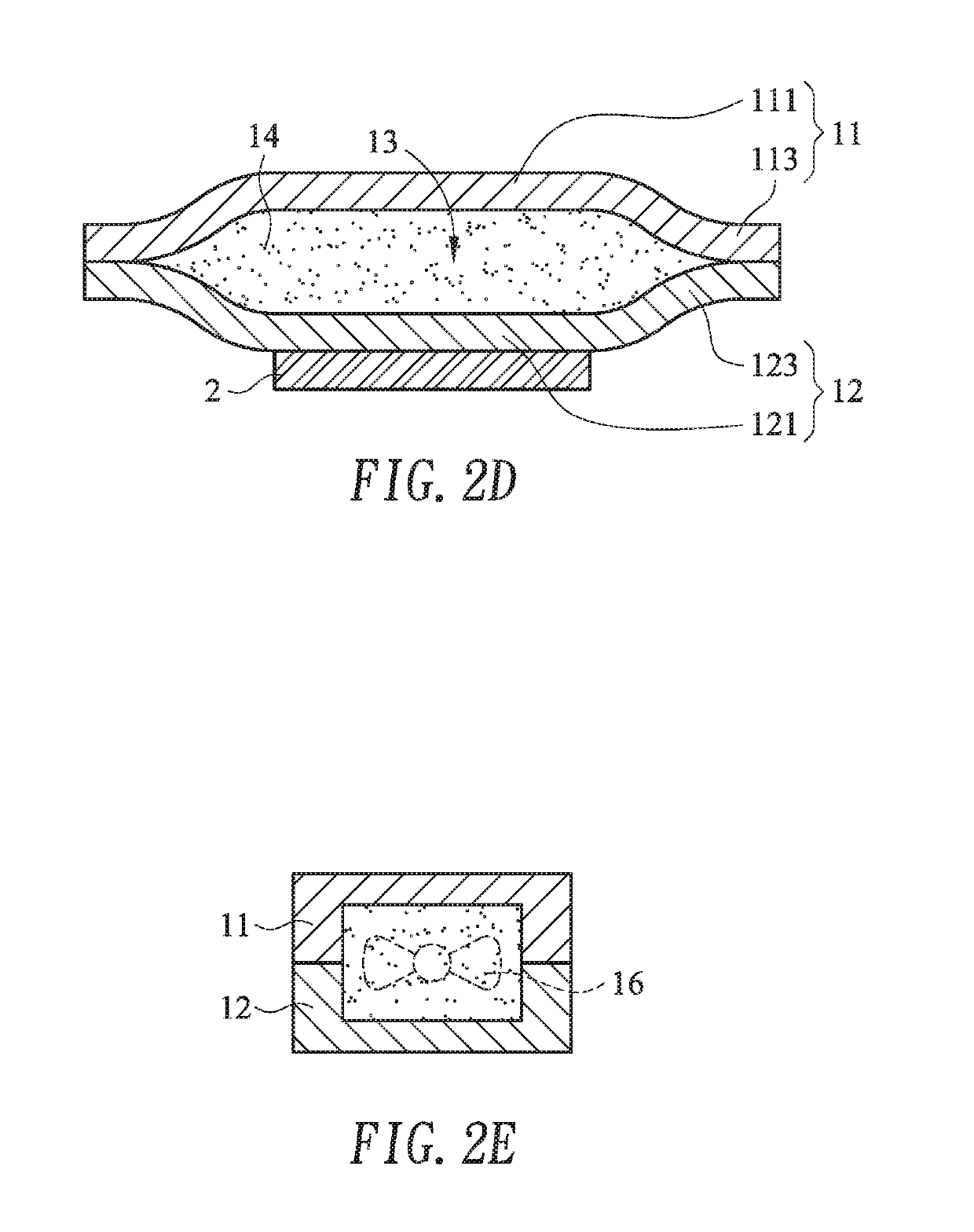

[0042]FIG. 3 is a schematic perspective view illustrating a liquid cooling device according to the present invention. FIG. 4A is a schematic cross-sectional view illustrating a heat-absorbing section of the liquid cooling device of FIG. 3 and taken along the line 4A-4A. FIG. 4B is a schematic cross-sectional view illustrating a first extension section of the liquid cooling device of FIG. 3 and taken along the line 4B-4B. FIG. 4C is a schematic cross-sectional view illustrating a second extension section of the liquid cooling device of FIG. 3 and taken along the line 4C-4C.

[0043]Please refer to FIGS. 3, 4A, 4B and 4C. In this embodiment, the liquid cooling device 3 comprises an upper plate 31, a lower plate 32, a liquid cooling radiator 35 and a driving device 36. The upper plate 31 and the lower plate 32 are combined together to define a chamber 33. A liquid working medium 34 is accommodated within the chamber 33. The chamber 33 comprises a heat-absorbing section 331, a first extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com