Long rod polishing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

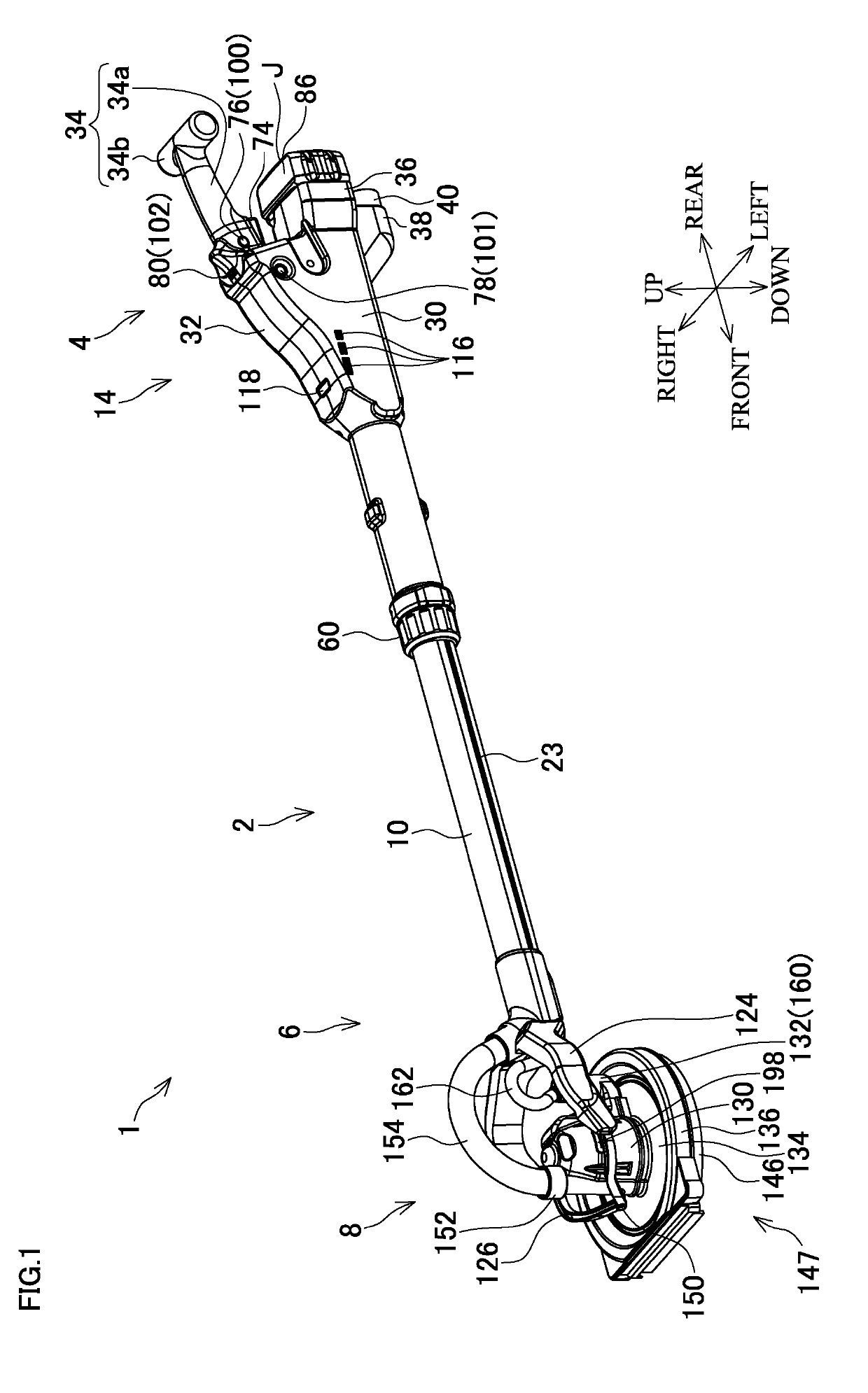

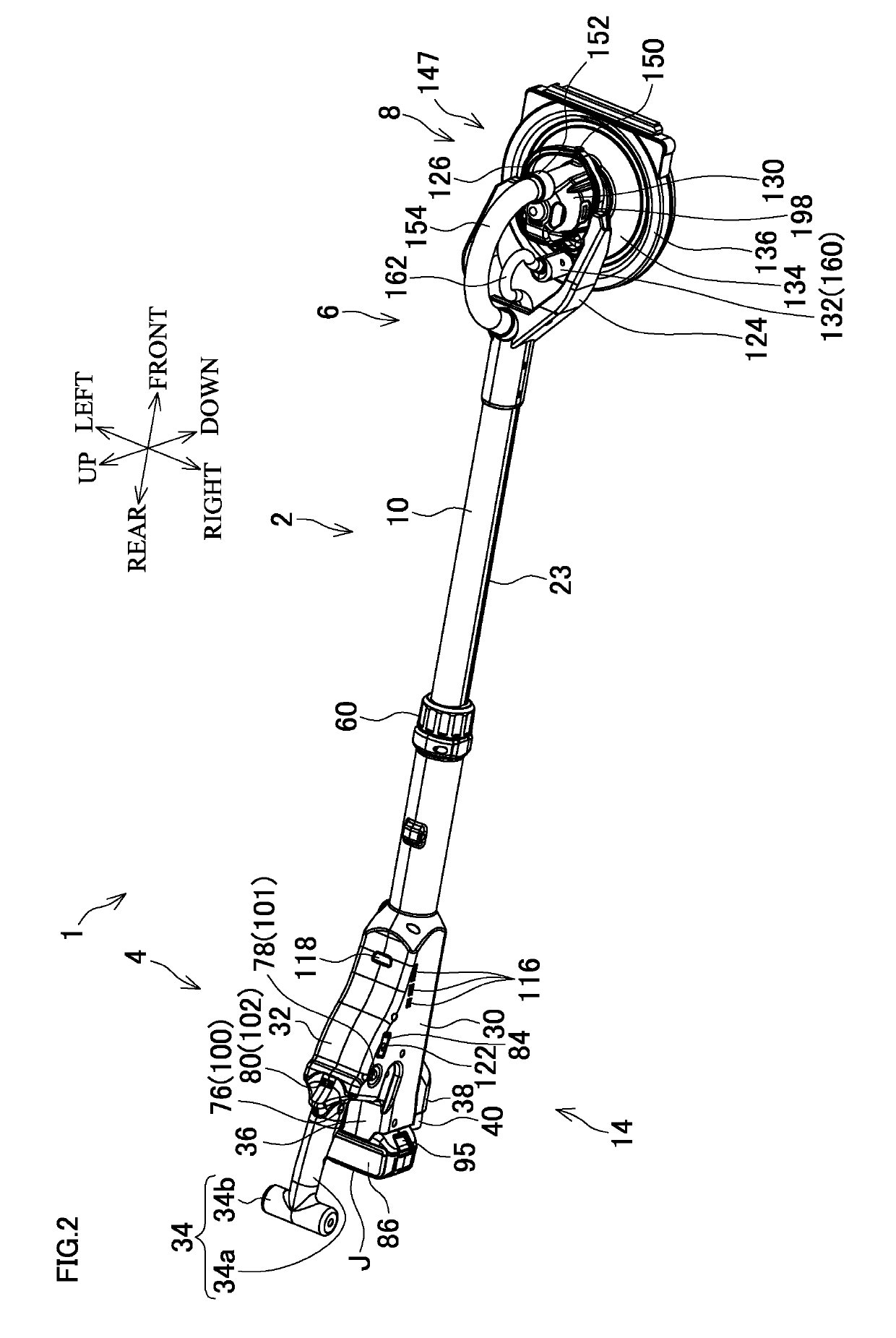

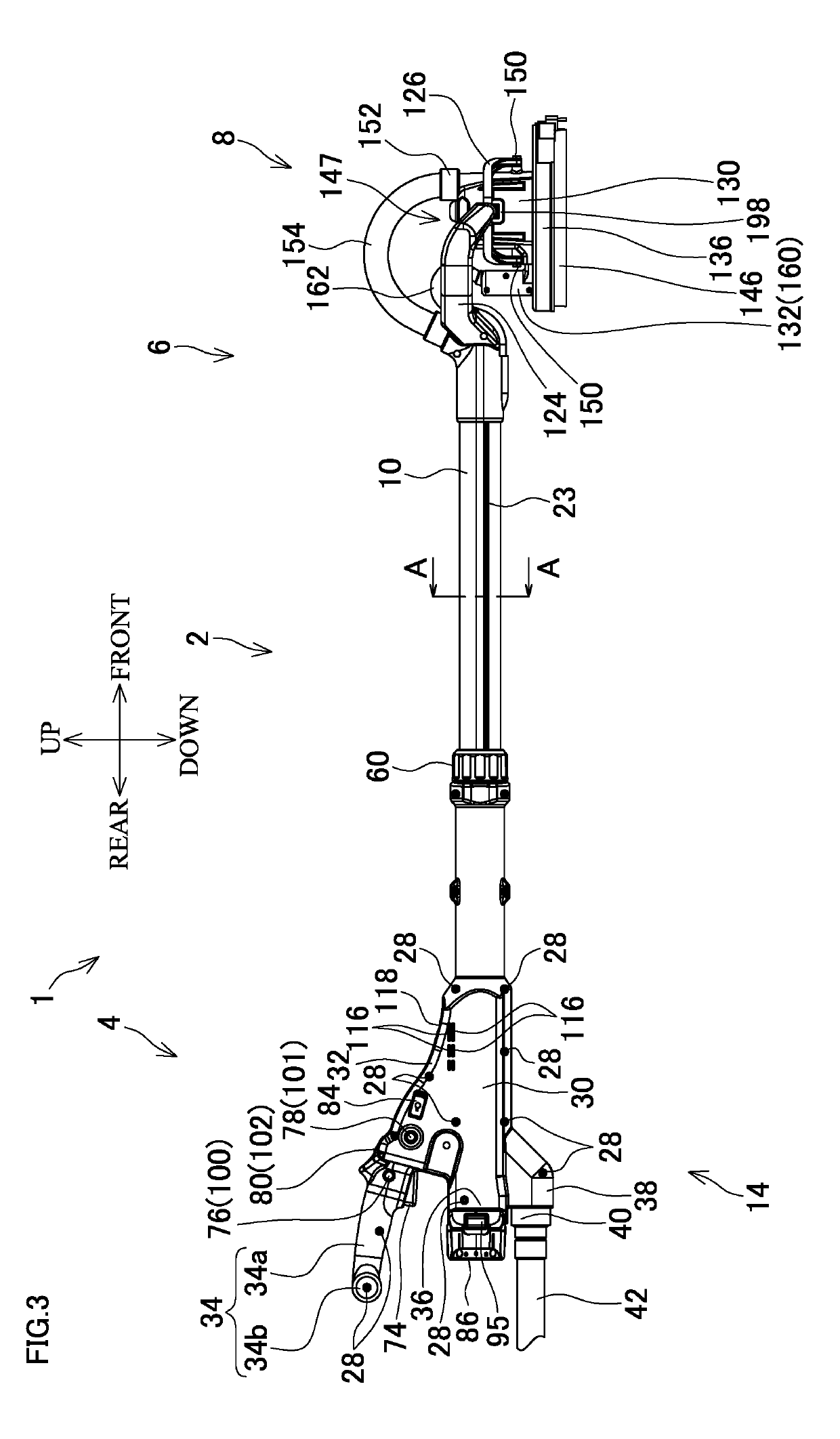

[0053]FIG. 1 is a perspective view when a dry wall sander 1 according to the first embodiment of the disclosure is viewed from a left side. FIG. 2 is a perspective view when the dry wall sander 1 is viewed from a right side. FIG. 3 is a right side view of the dry wall sander 1. FIG. 4 is a front view of the dry wall sander 1. FIG. 5 is a center vertical cross-sectional view of a front of a rear portion of the dry wall sander 1. FIG. 6 is a center vertical cross-sectional view of a rear of the rear portion of the dry wall sander 1. FIG. 7 is a center vertical cross-sectional view of a front portion of the dry wall sander 1. FIG. 8 is a cross-sectional view taken along a line B-B in FIG. 6. FIG. 9 is a cross-sectional view taken along a line A-A in FIG. 3. FIG. 10 is a drawing equivalent to FIG. 1 and illustrates the dry wall sander in a state where the rod portion 2 is at its shortest length.

[0054]The dry wall sander 1 includes a rod portion 2, a handle portion 4, which is disposed a...

second embodiment

[0165]FIG. 11 is a drawing similar to FIG. 2 where a front portion is omitted in a dry wall sander 251 according to the second embodiment of the disclosure. FIG. 12 is a drawing similar to FIG. 3 where the front portion is omitted in the dry wall sander 251.

[0166]Excluding the number of and a location of battery mounting portions and the number of batteries, the dry wall sander 251 is configured similarly to the dry wall sander 1 according to the first embodiment. Hereinafter, identical reference numerals are given to parts configured similarly to those of the first embodiment and their descriptions are appropriately omitted.

[0167]The dry wall sander 251 includes a handle housing 264 that includes two battery mounting portions 286 in a handle portion 254.

[0168]The one battery mounting portion 286 is located on the right surface of the handle housing 264 and at the rear portion of the rod housing portion 30. The other battery mounting portion 286 is located on the left surface of the...

third embodiment

[0187]FIG. 13 is a drawing similar to FIG. 2 where a front portion is omitted in a dry wall sander 301 according to the third embodiment of the disclosure. FIG. 14 is a drawing similar toFIG. 3 where the front portion is omitted in the dry wall sander 301.

[0188]Excluding a location of a battery mounting portion, the dry wall sander 301 is configured similarly to the dry wall sander 1 according to the first embodiment. Hereinafter, identical reference numerals are given to parts configured similarly to those of the first embodiment and their descriptions are appropriately omitted.

[0189]A battery mounting portion 336 is formed between the speed adjustment dial 80 and the display unit 118 at a top of a handle housing 314 in a handle portion 304 of the dry wall sander 301.

[0190]The battery 86 is mountable to the battery mounting portion 336. While the longest side J of the battery 86 is in the front-rear direction and the battery button 95 is on the front side, the battery 86 is mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com