Dies for manufacturing shims

a technology for manufacturing shims and shims, which is applied in the direction of manufacturing tools, ejection devices, shaping tools, etc., can solve the problems of degrading the quality of the shim and the damage of the shim, and achieve the effects of preventing the degradation of the shim quality, reducing the loss of materials, and quick collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Hereinbelow, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the embodiments are merely provided for easy understanding of the invention, so the present invention is not limited thereto.

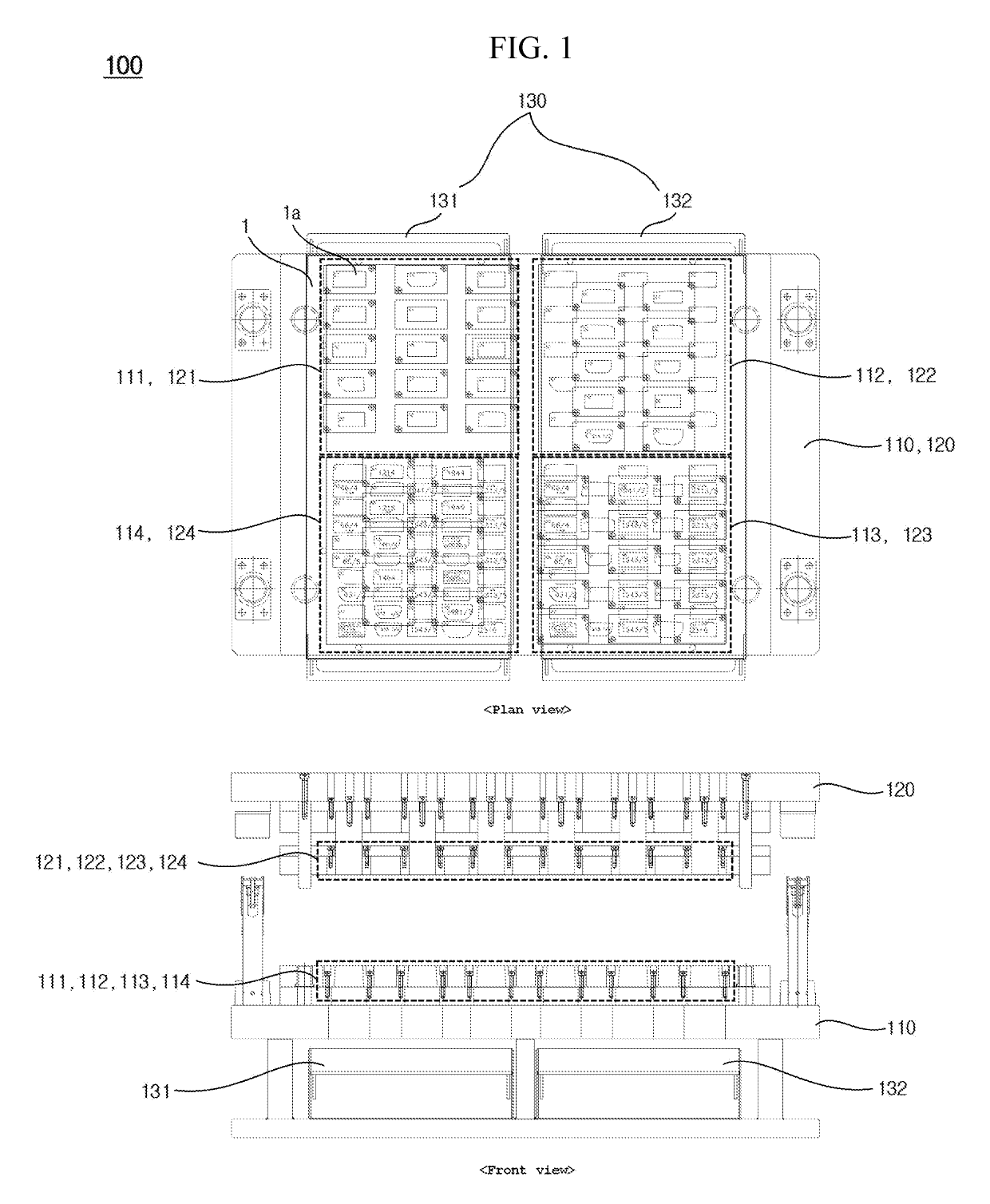

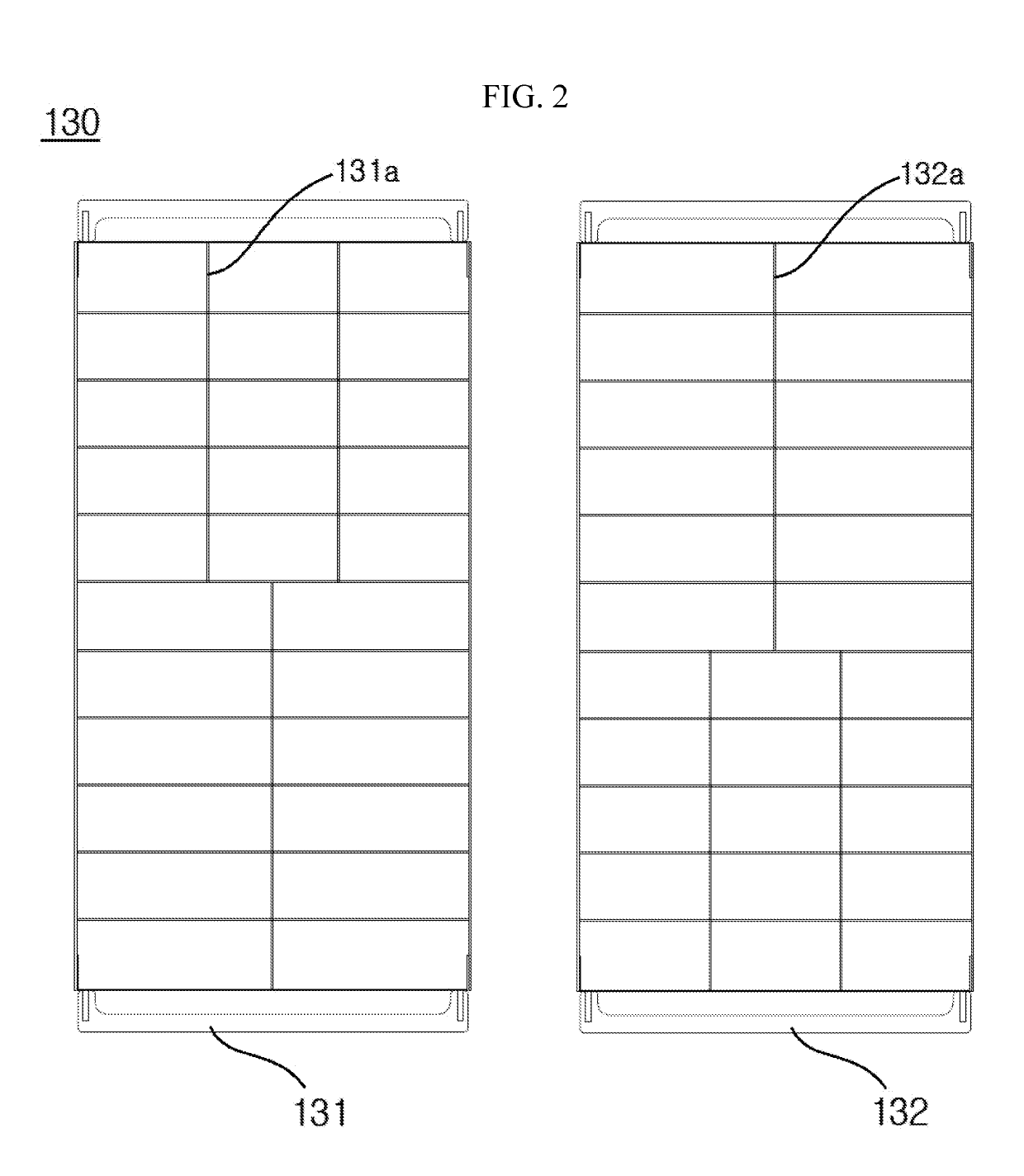

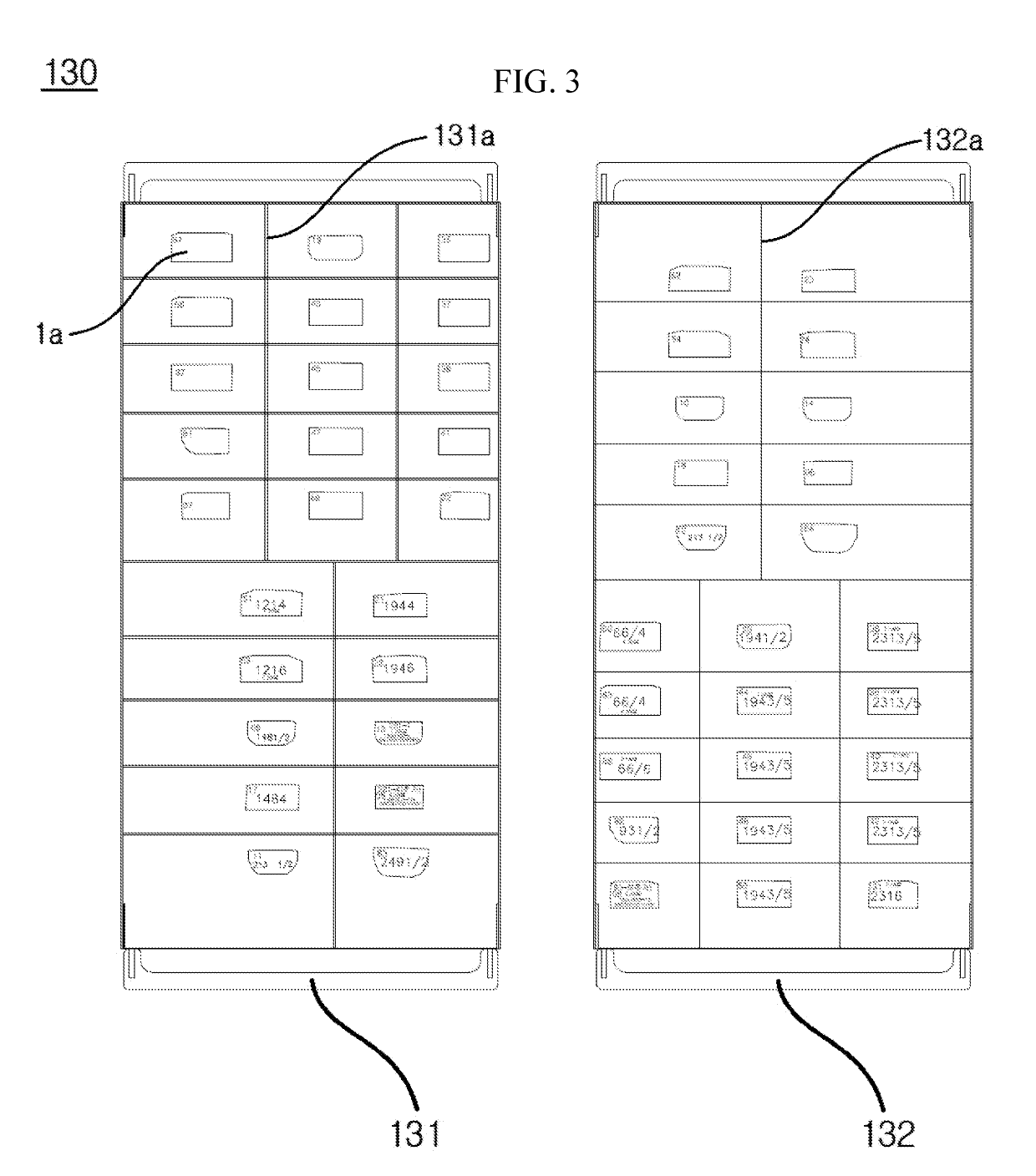

[0030]FIG. 1 is a view illustrating a configuration of a die 100 for manufacturing shims according to an embodiment of the present invention.

[0031]Referring to FIG. 1, the die 100 may generally include a lower die block 110, an upper die block 120, and a collecting box 130.

[0032]The lower die block 110 may serve as a place on which a source material plate for a shim is seated and located, with a plurality of die divisions formed on an upper surface thereof.

[0033]Specifically, the lower die block 110 may be divided into first to fourth die units 111, 112, 113, 114 adjacent to first to fourth sides thereof (not shown).

[0034]Here, the first to fourth die units 111, 112, 113, 114 may be coupled to an upper surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rigidity | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| vertical movement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com