Process for manufacturing a hybrid timepiece component

a technology of hybrid timepieces and components, applied in the field of hybrid timepiece components manufacturing, can solve the problems of ensuring the cohesion of the assembly, unable to meet the requirements of mechanical strength, and the timepiece components obtained exhibit a risk of cohesive failure between the two materials, so as to achieve satisfactory mechanical strength and cohesion. the effect of a hybrid timepiece componen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]For the sake of simplification, the term “metal” will be used in the following description to denote a metallic material or a metal alloy. Furthermore, the same references will be used for identical or similar elements in the various embodiment variants of the invention.

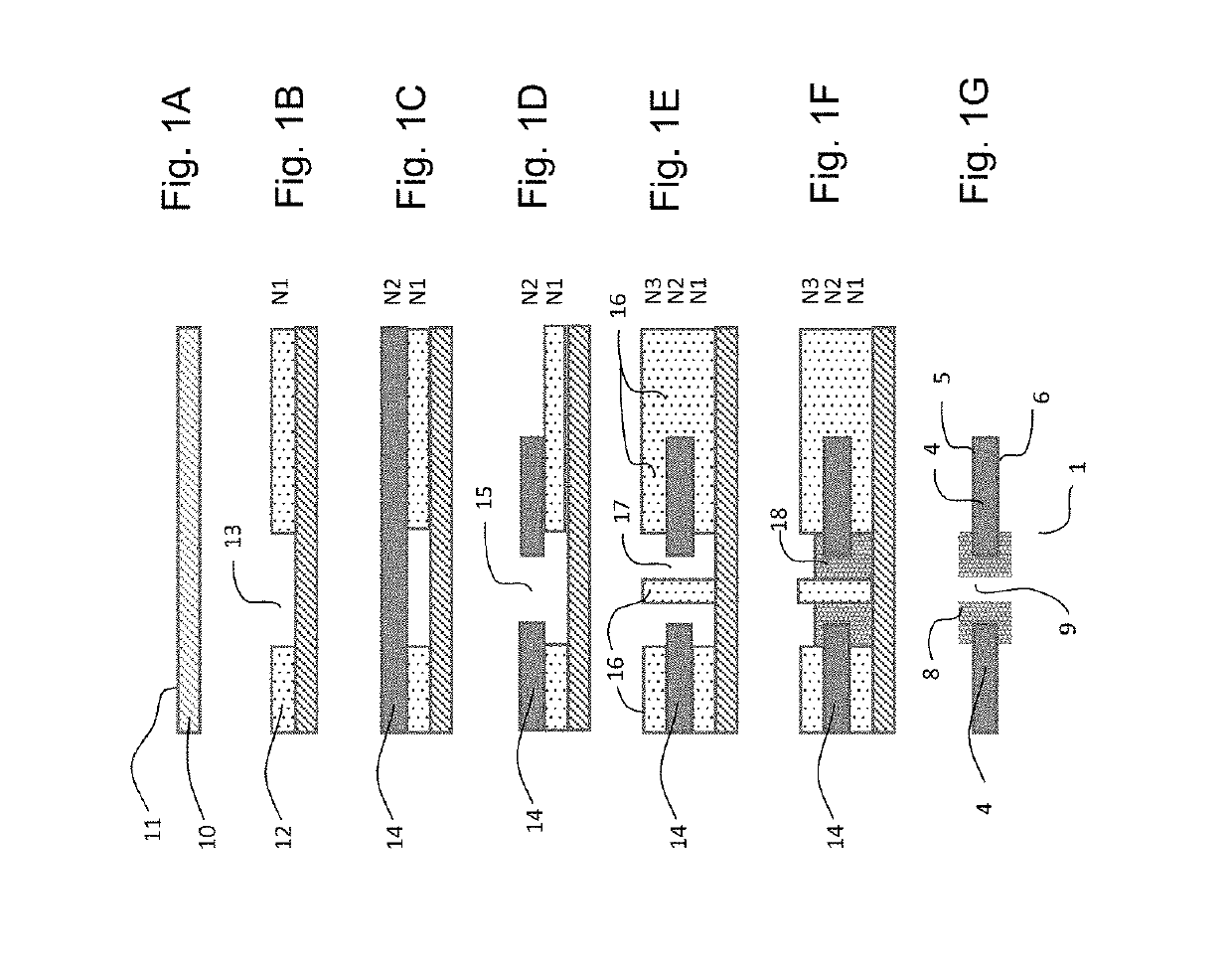

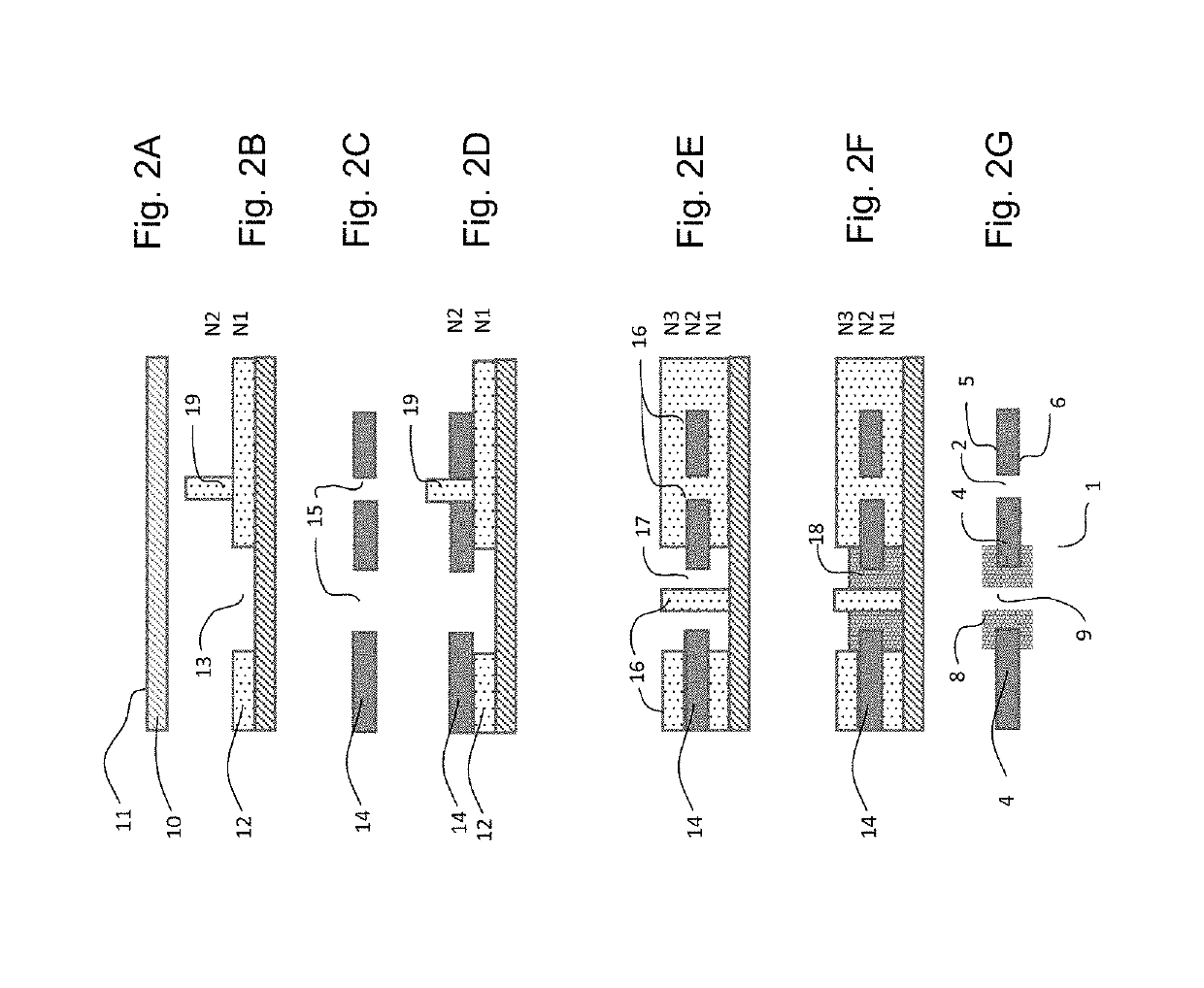

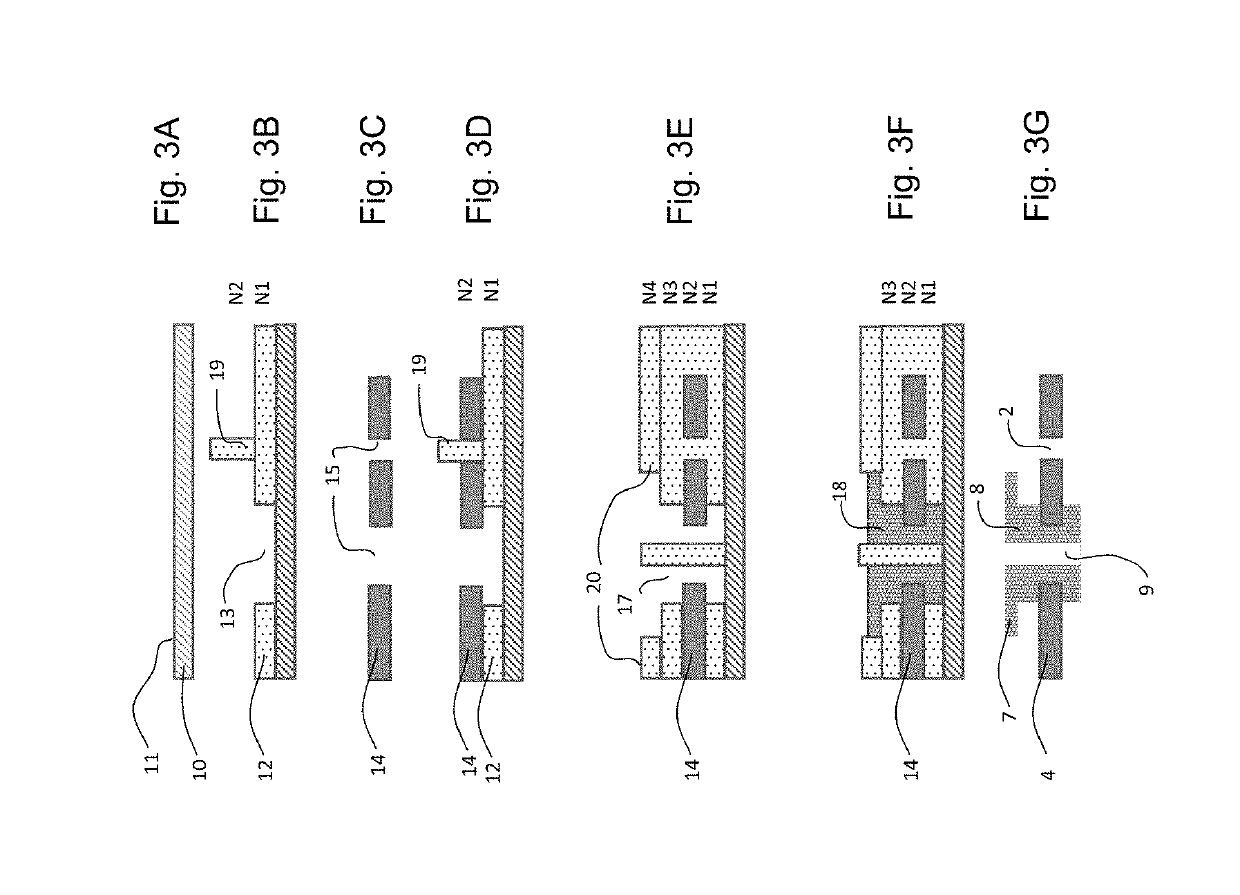

[0020]FIG. 1a illustrates a first step of the process for manufacturing a hybrid timepiece component according to the embodiment of the invention. This step consists in being provided with a working substrate 10 that will act as support for the fabrication of the timepiece component. This substrate is intended to be removed, that is to say that it is not part of the final timepiece component. It is either made of metal or made of any conductive material, or formed using a nonconductive material, the upper surface 11 of which is rendered conductive by metallization. Thus, the working substrate may consist of a silicon wafer comprising a metal layer obtained by PVD deposition or by electroforming, or of a doped s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| deposition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com