Apparatus and method for shaping drywall mud

a technology of drywall mud and apparatus, which is applied in the field of drywall hanging and finishing, can solve the problems of operator losing the time that might have been saved using the disclosed tool, the prior art device described, and the inability to adapt to changing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

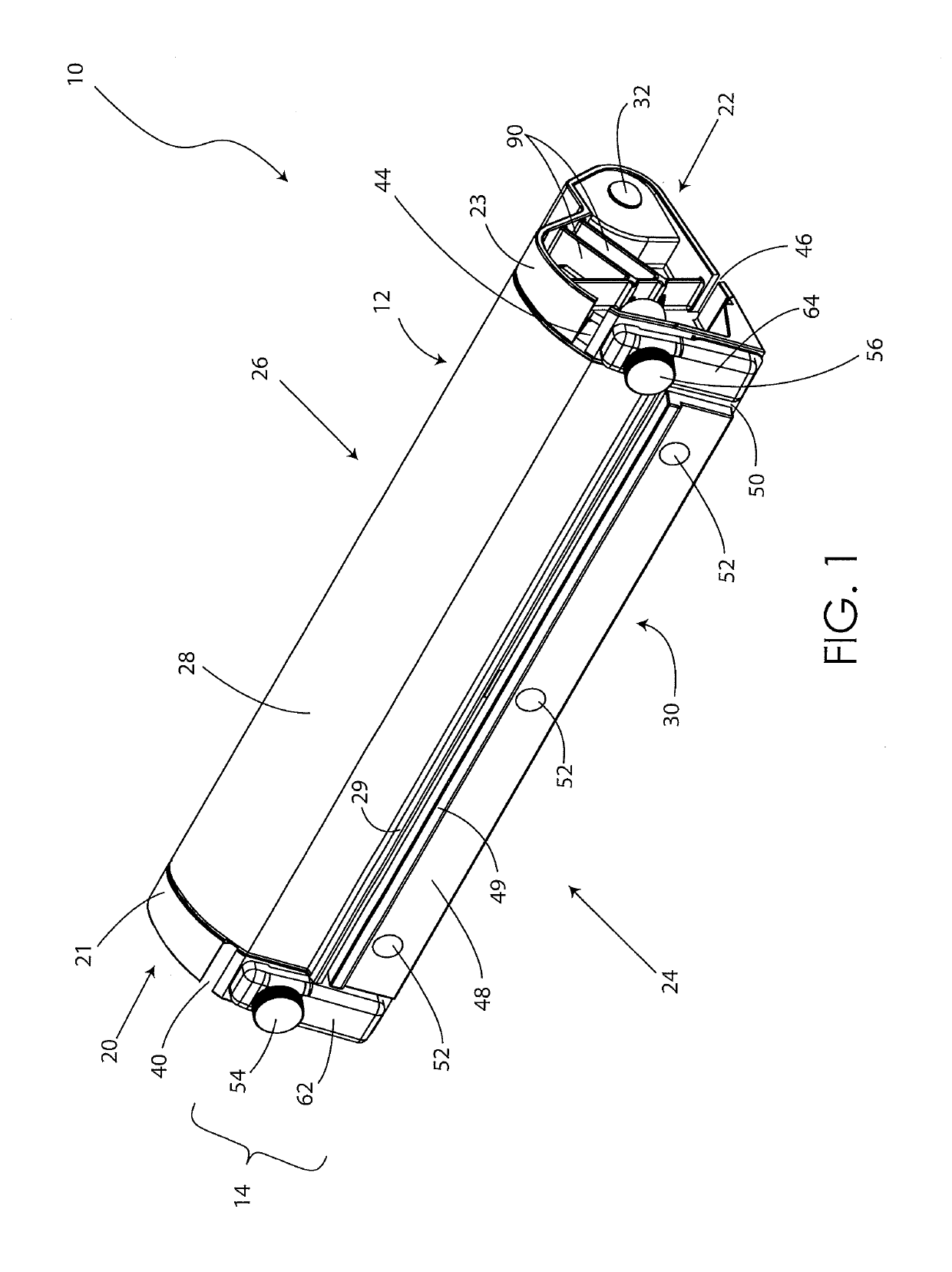

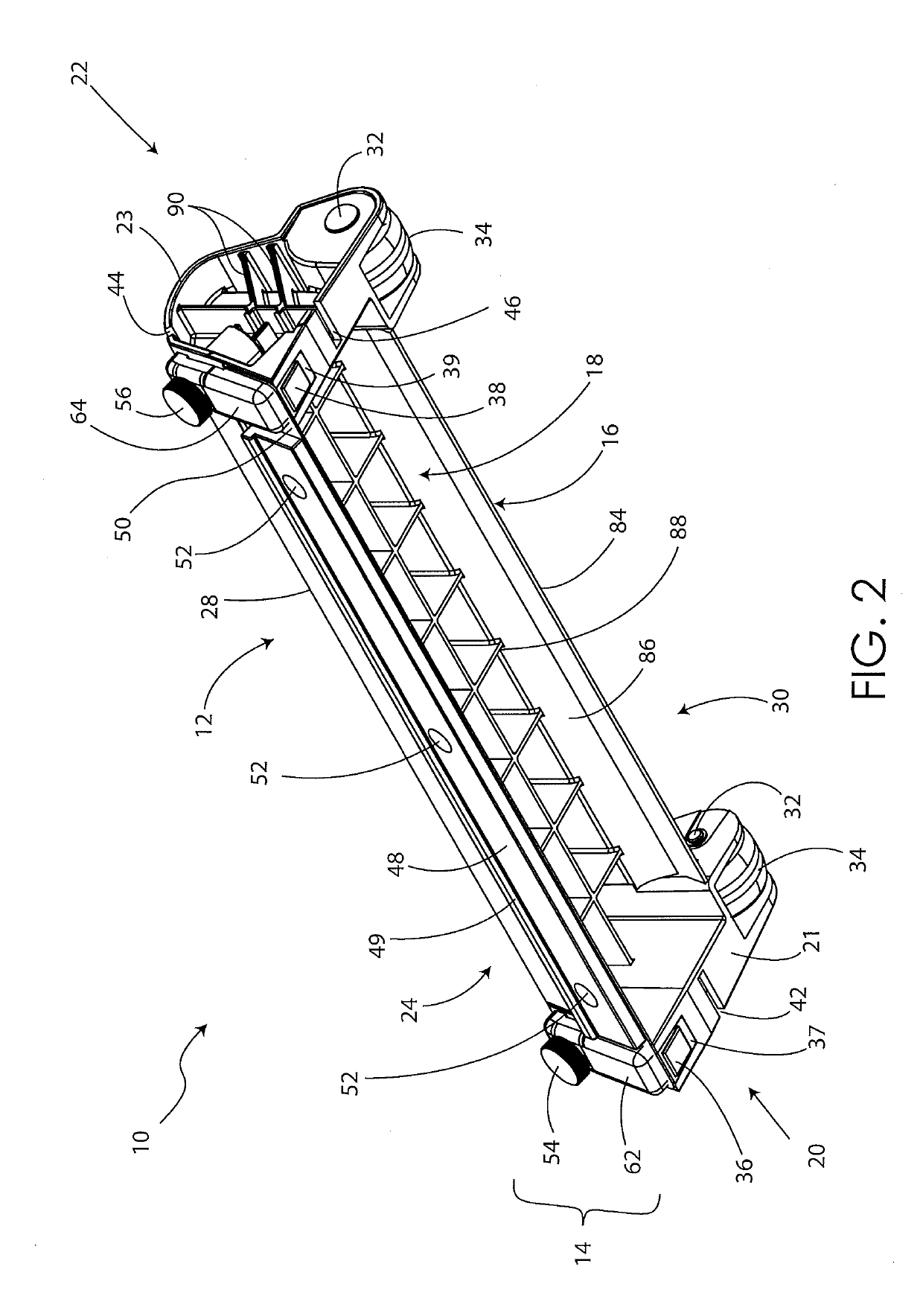

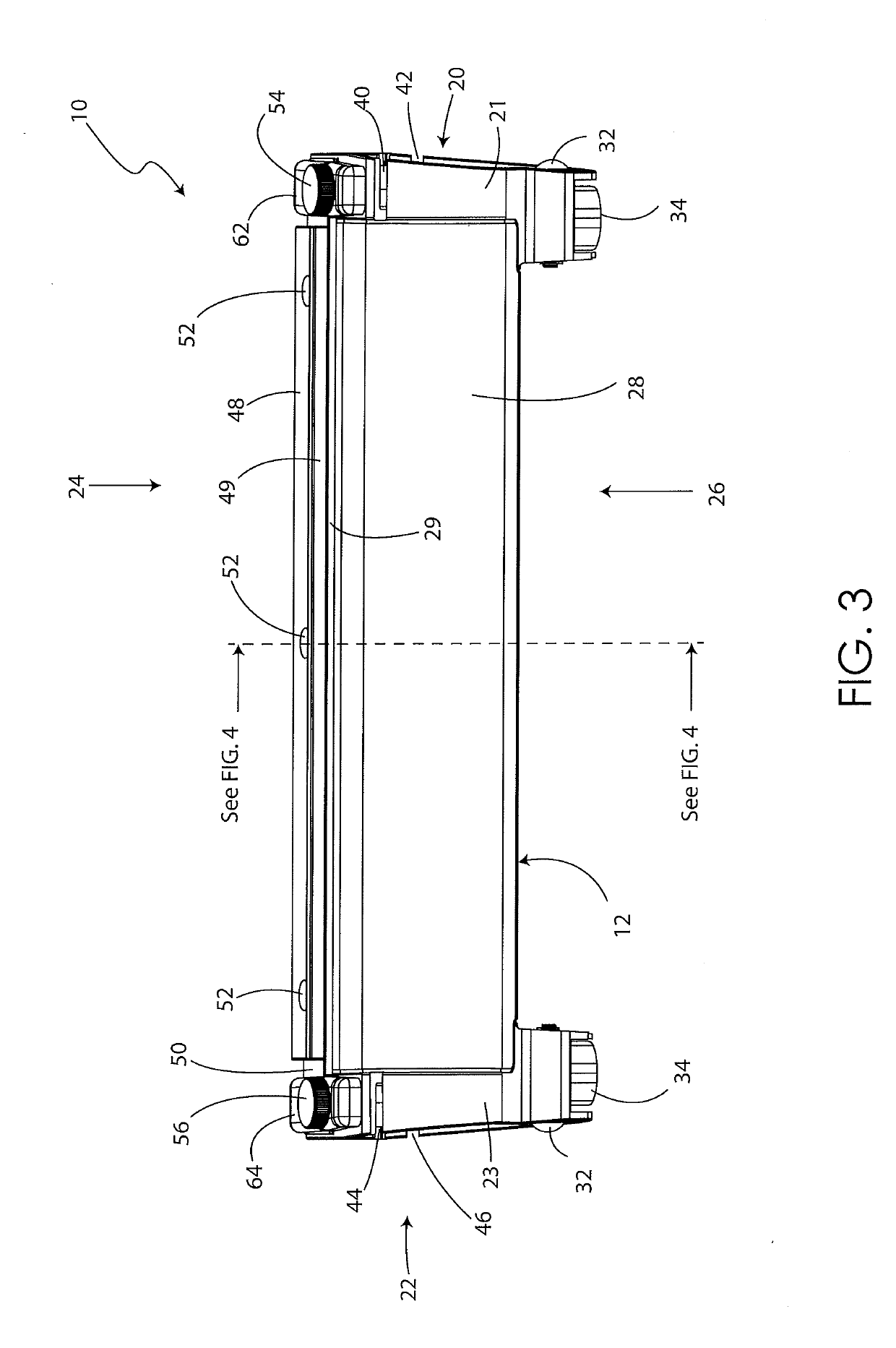

[0031]With reference to the FIGS, a drywall mud-shaping tool 10 is provided. The shaping tool 10 includes a main body 12, a blade assembly 14, a wiper assembly 16 (FIG. 2), and a collection chamber 18.

[0032]With reference to FIGS. 1-3 and 7-11, main body 12 of the shaping tool 10 includes a first end 20, a second end 22, a front side 24, a rear side 26, a top 28 and a bottom 30. First end 20 and second end 22 are spaced apart defining therebetween a longitudinal direction. Front side 24 is spaced apart from rear 26 defining therebetween a transverse direction. Top 28 is spaced apart from bottom 30 defining therebetween a vertical direction.

[0033]Main body 12 can be fabricated as a single piece via injection molding and can be fabricated from a plastic material, such as acrylonitrile butadiene styrene plastic (ABS plastic), polyvinyl chloride plastic (PVC plastic), or polycarbonate, or main body 12 may be constructed of metal.

[0034]According to another aspect, main body 12 can be fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com