Production and application of fire resistant erosion control mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

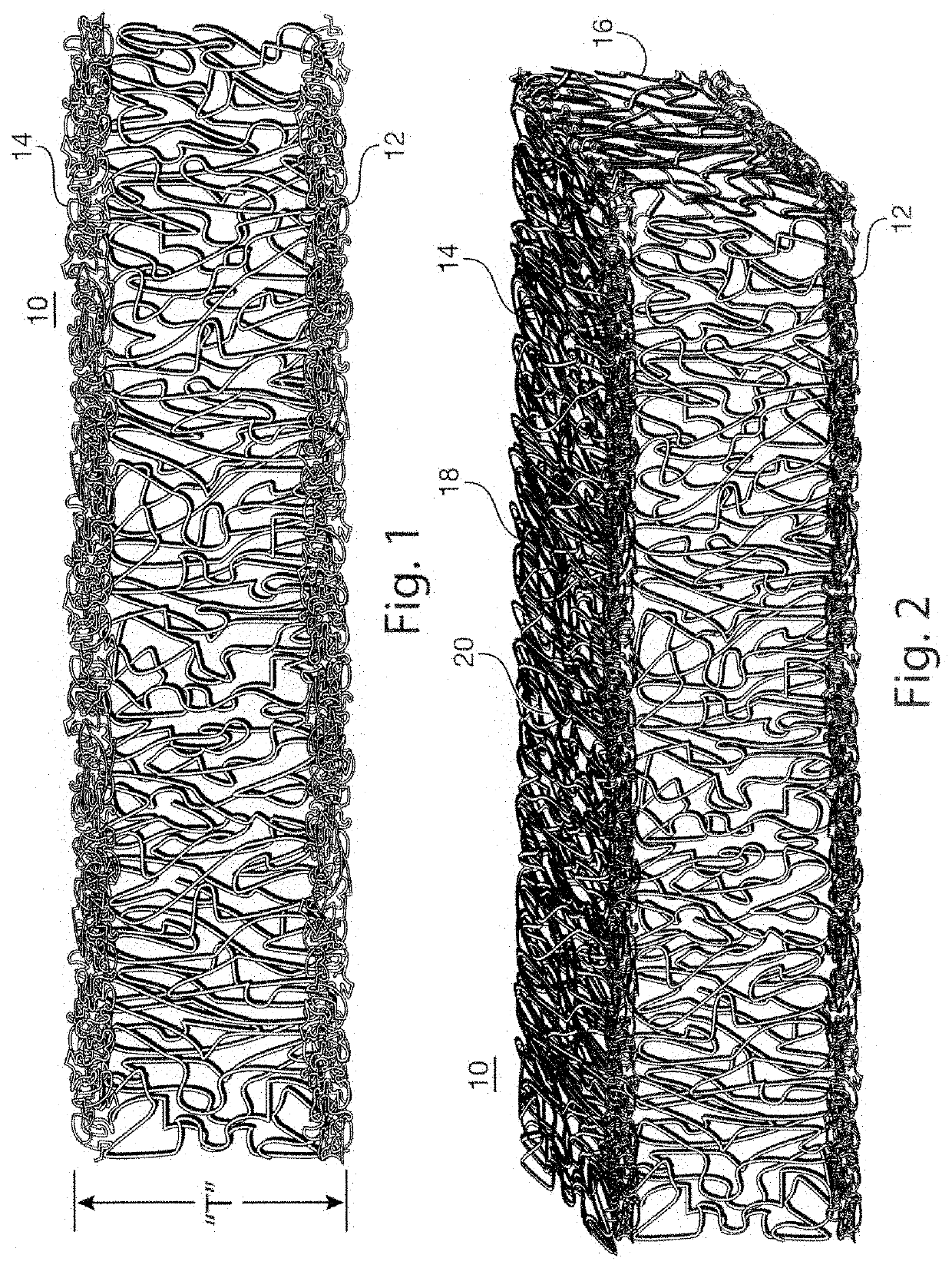

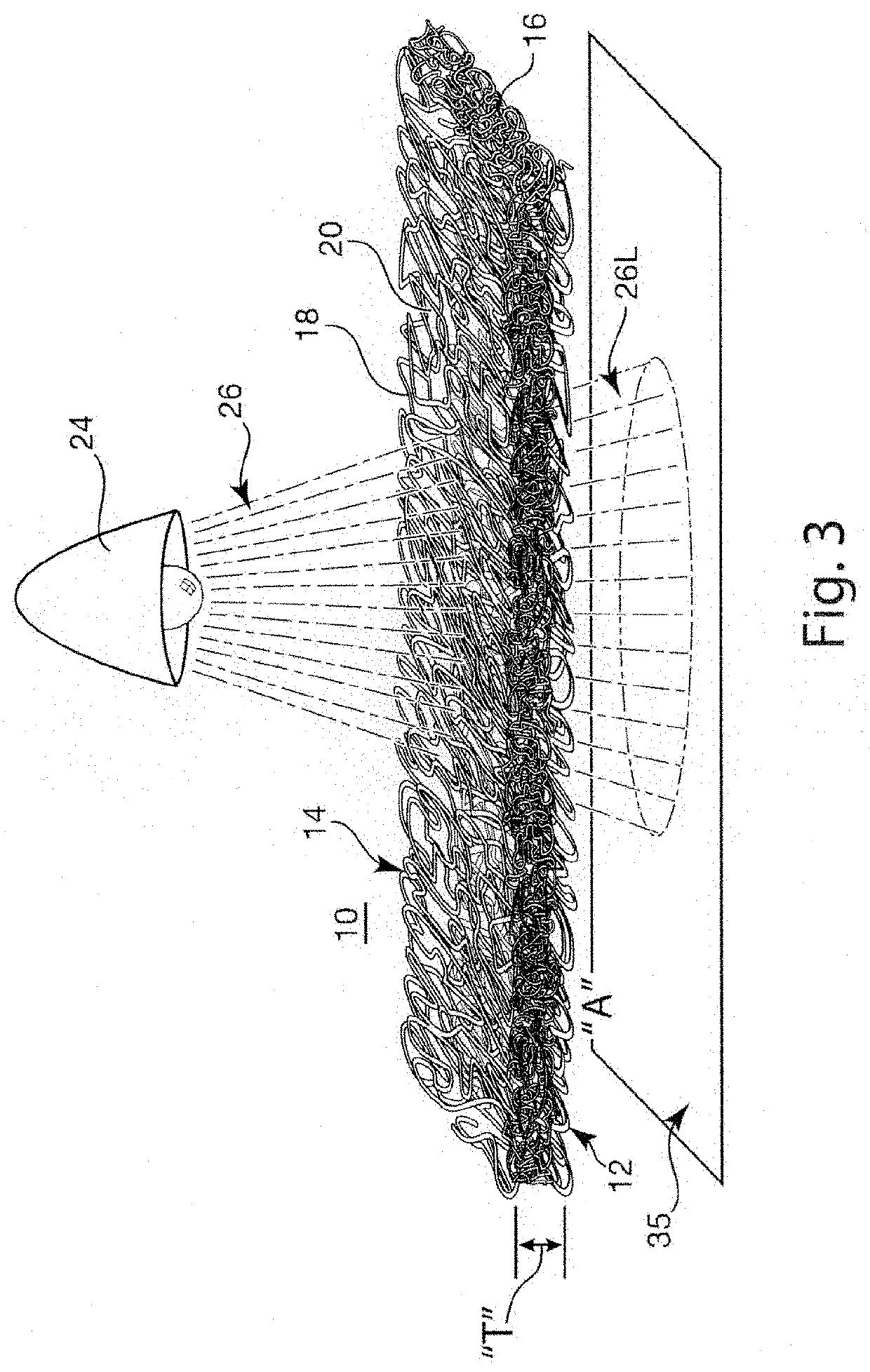

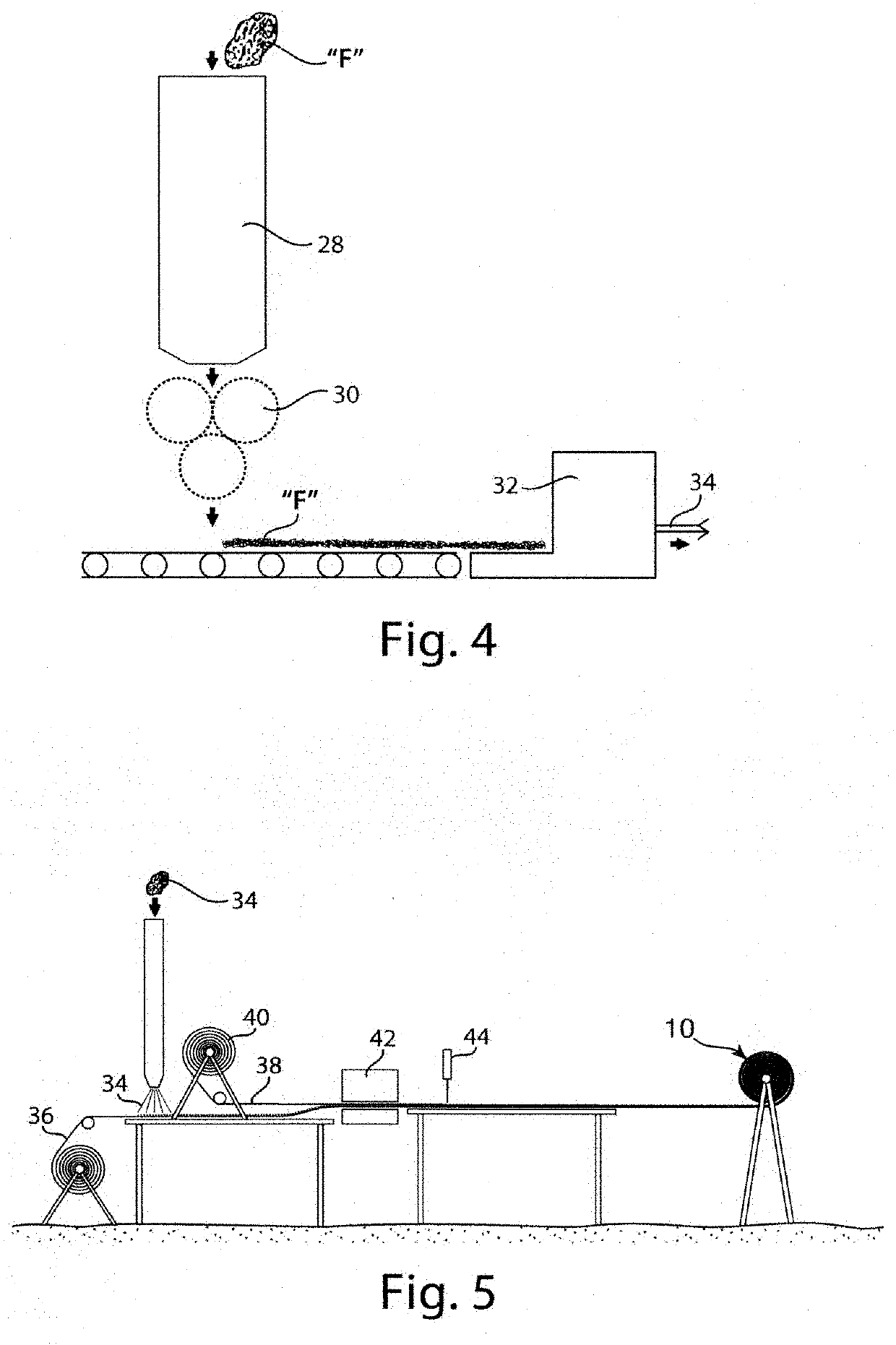

[0039]Referring now to the details of the drawings, the present invention as shown in FIG. 1 comprises an elongated, flexible, fire-resistant, multi-layered mat 10 comprised of an elongated, fire resistant lower netting 12, an elongated fire resistant upper netting14 and an elongated, fire-resistant, light and air-penetrable inner layer 16.

[0040]The elongated, flexible, fire-resistant lower netting 12 is preferably comprised of a web of woven or roll-pressed or stamped, porous or foraminous, air and light transmissive layer of metal such as stainless steel, galvanized steel, aluminum, tin, or a fire resistant plastic or polyvinyl chloride material, as represented in FIGS. 1 and 2. Such lower netting 12 may also be comprised of a chain link type arrangement, having smaller openings of a range of one quarter inch to one inch across.

[0041]The elongated, flexible, fire-resistant upper netting 14 is also preferably comprised of a woven or roll-pressed or stamped, foraminous, porous, air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com