System of manufacturing injection molded article and metal mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

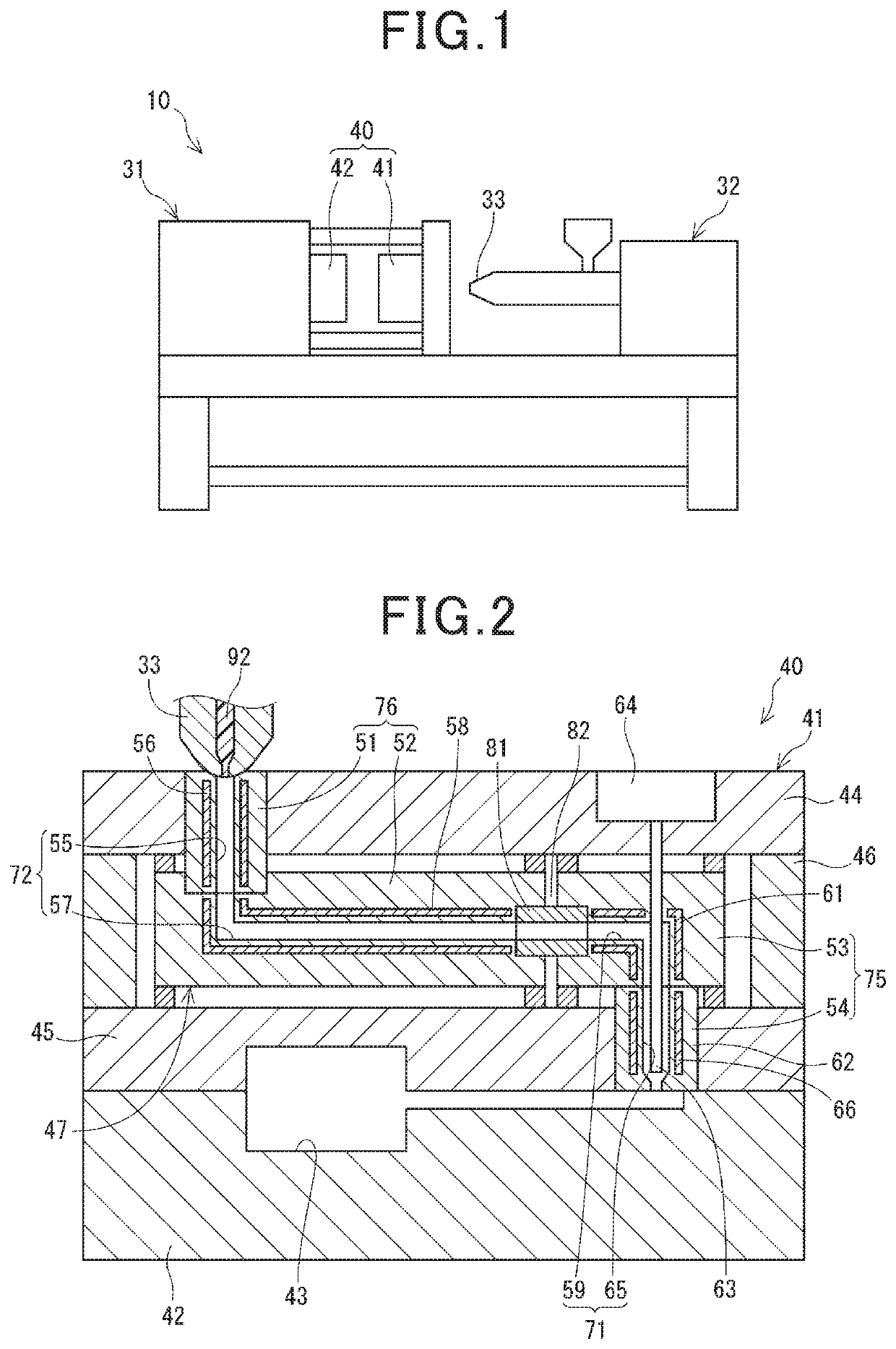

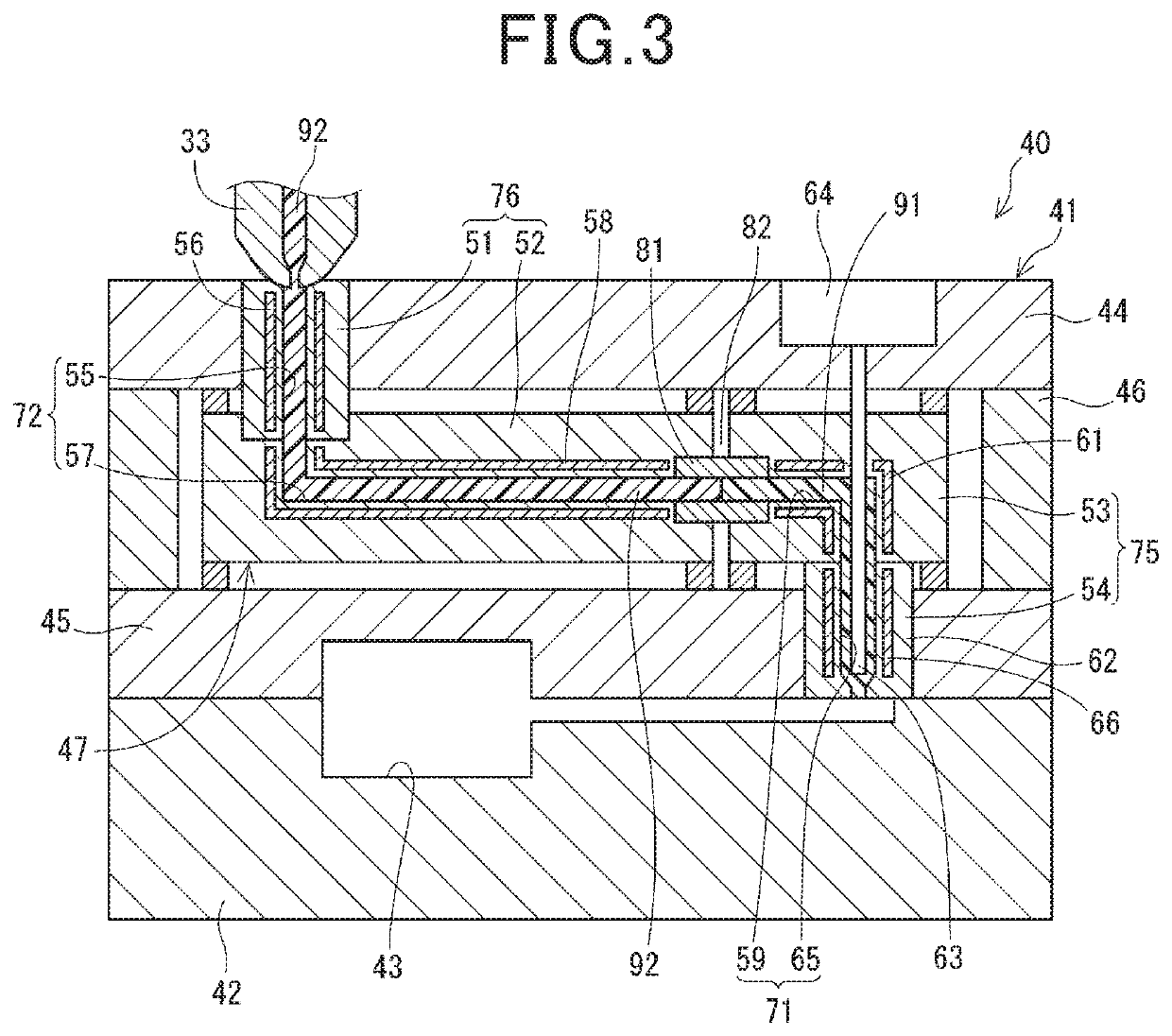

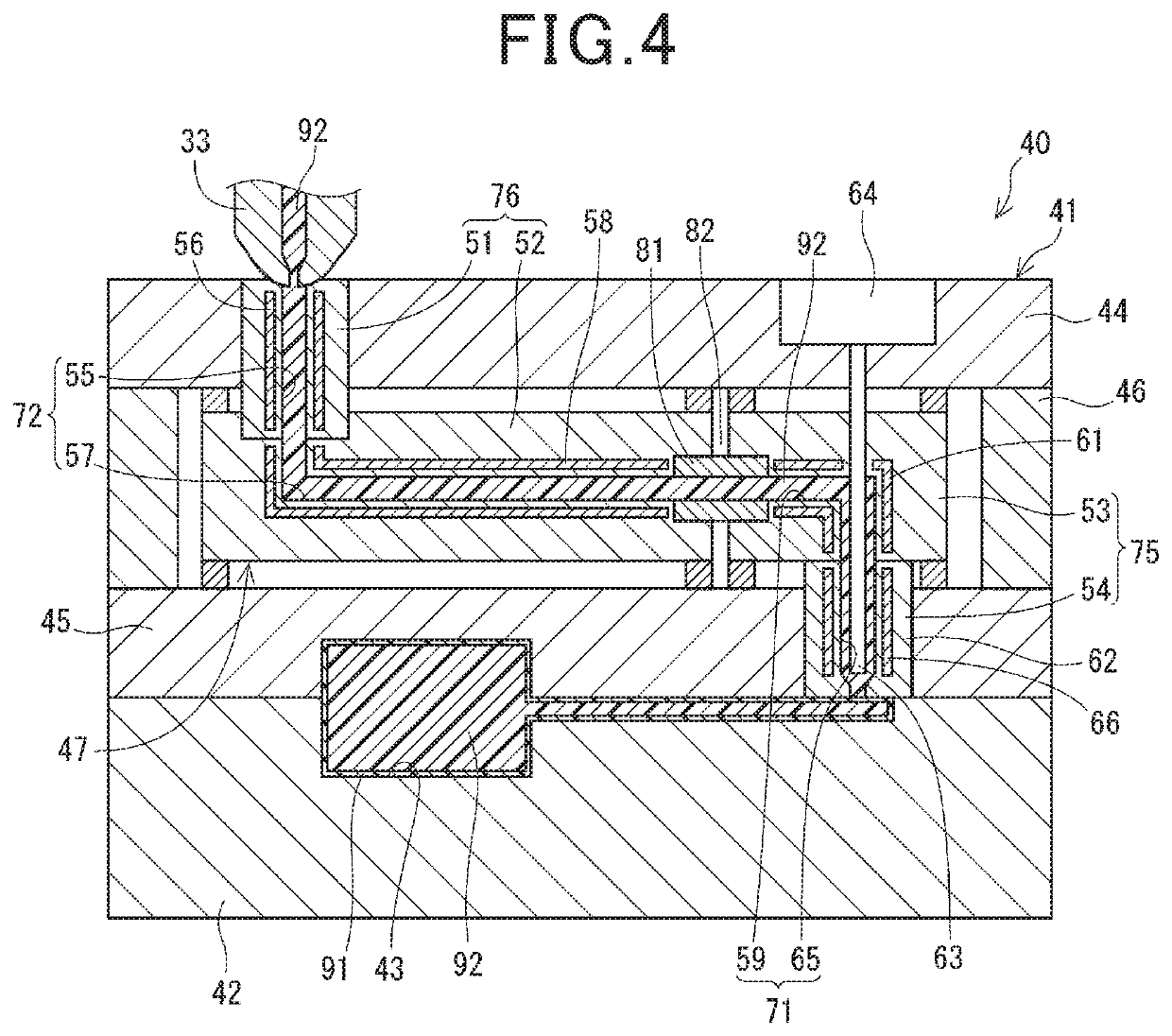

[0021]Referring now to the drawings, wherein like reference numerals designate identical or corresponding parts throughout the several views thereof, and in particular to FIG. 1, an injection molding machine 10 is provided to manufacture a molded article by performing injection molding. The injection molding is a system to obtain a molded article (i.e., an injection molded article) by injecting molten material into a metal mold 40 and cooling and solidifying the molten material.

[0022]The injection molding machine 10 includes a mold fastening section 31 and an injection section 32. The injection section 32 heats and melts resin material and injects a melting result into the metal mold 40. (Hence) The injection section 32 includes a molten resin supply source. The injection section 32 controls injection speed when resin flows thru the metal mold 40 and controls pressure when the metal mold 40 has been filled with the resin. The mold fastening section 31 opens and closes the metal mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap