Heat dissipation unit connection structure

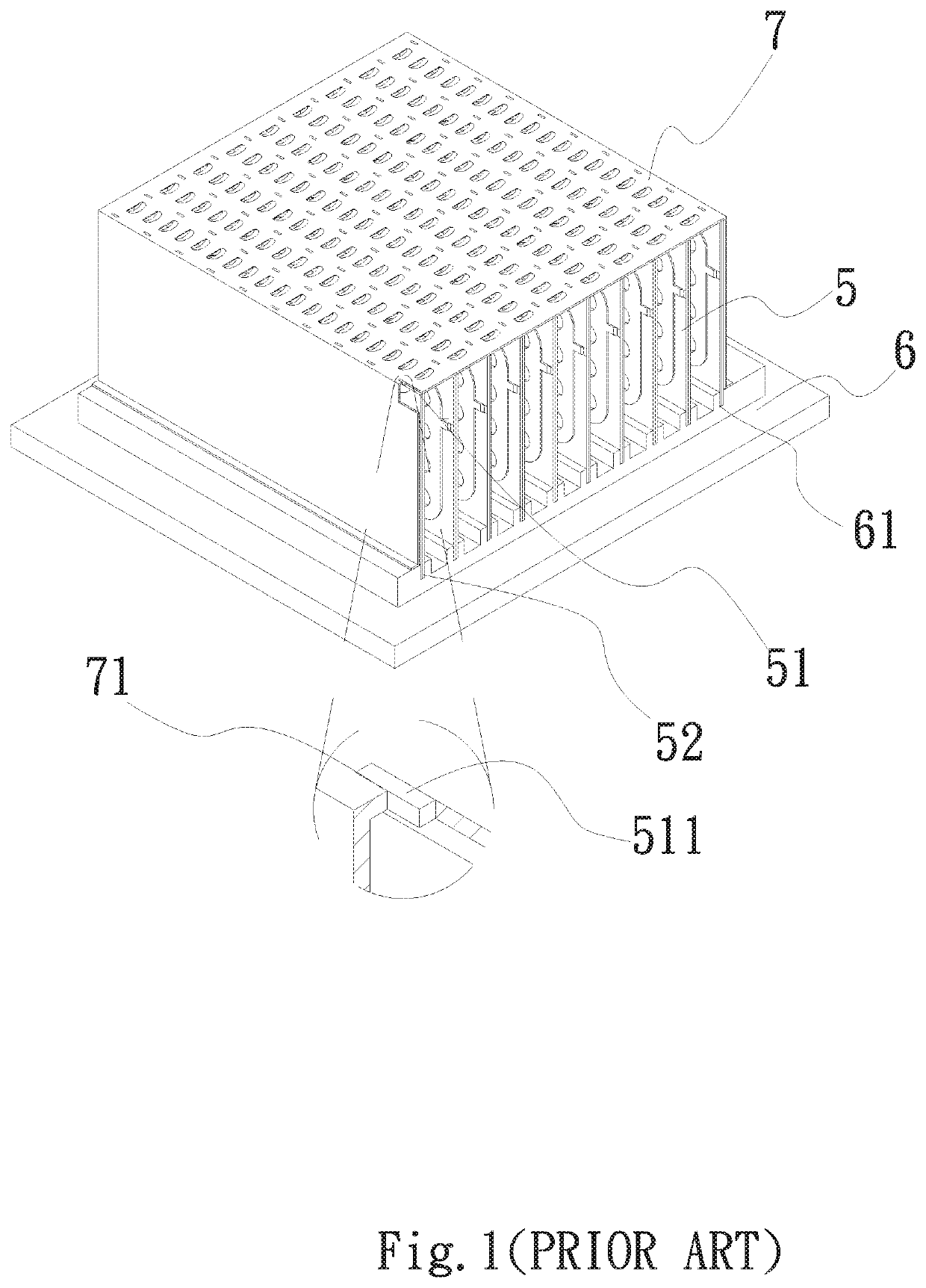

a heat dissipation unit and connection structure technology, applied in the direction of lighting and heating apparatus, stationary conduit assemblies, laminated elements, etc., can solve the problems of increasing difficulty in working, time-consuming, and complicated connection methods for assembling the plate body b>7/b> with the conventional roll-bond plate evaporator b>5/b>, so as to simplify the connection structure and process, shorten the working time, and simplify the effect of structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

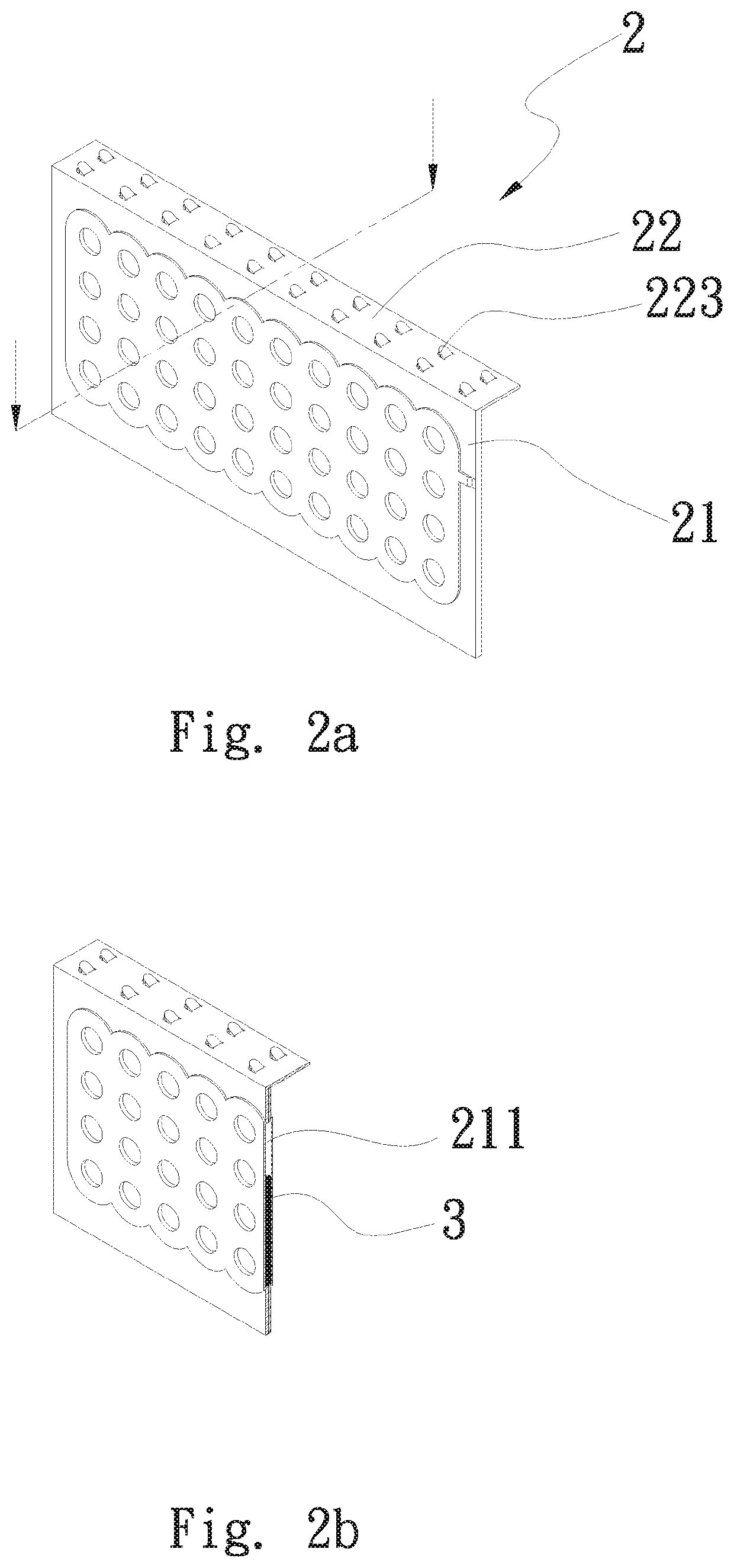

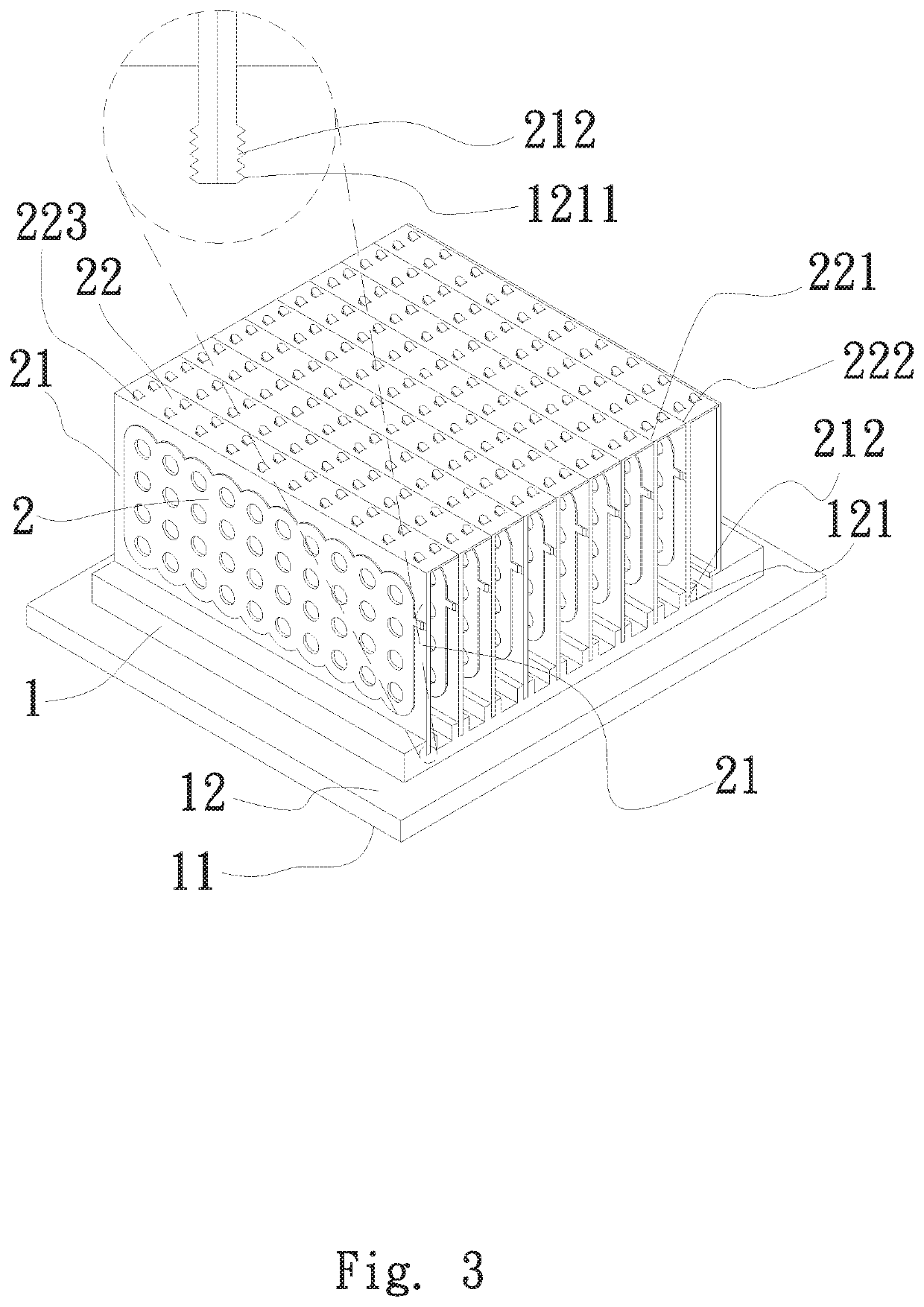

[0023]Please refer to FIGS. 2a, 2b and 3. FIG. 2a is a perspective view of the heat dissipation unit of a first embodiment of the heat dissipation unit connection structure of the present invention. FIG. 2b is a perspective sectional view of the heat dissipation unit of the first embodiment of the heat dissipation unit connection structure of the present invention. FIG. 3 is a perspective assembled view of the first embodiment of the heat dissipation unit connection structure of the present invention. According to the first embodiment, the heat dissipation unit connection structure of the present invention includes a substrate 1 and multiple heat dissipation units 2.

[0024]The substrate 1 has a first face 11 and a second face 12. The first and second faces 11, 12 are respectively positioned on an upper side and a lower side of the substrate 1. The first face 11 is in contact with at least one heat source (not shown) to conduct the heat of the heat source. The second face 12 is formed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap