Totally Aerated Combustion Burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

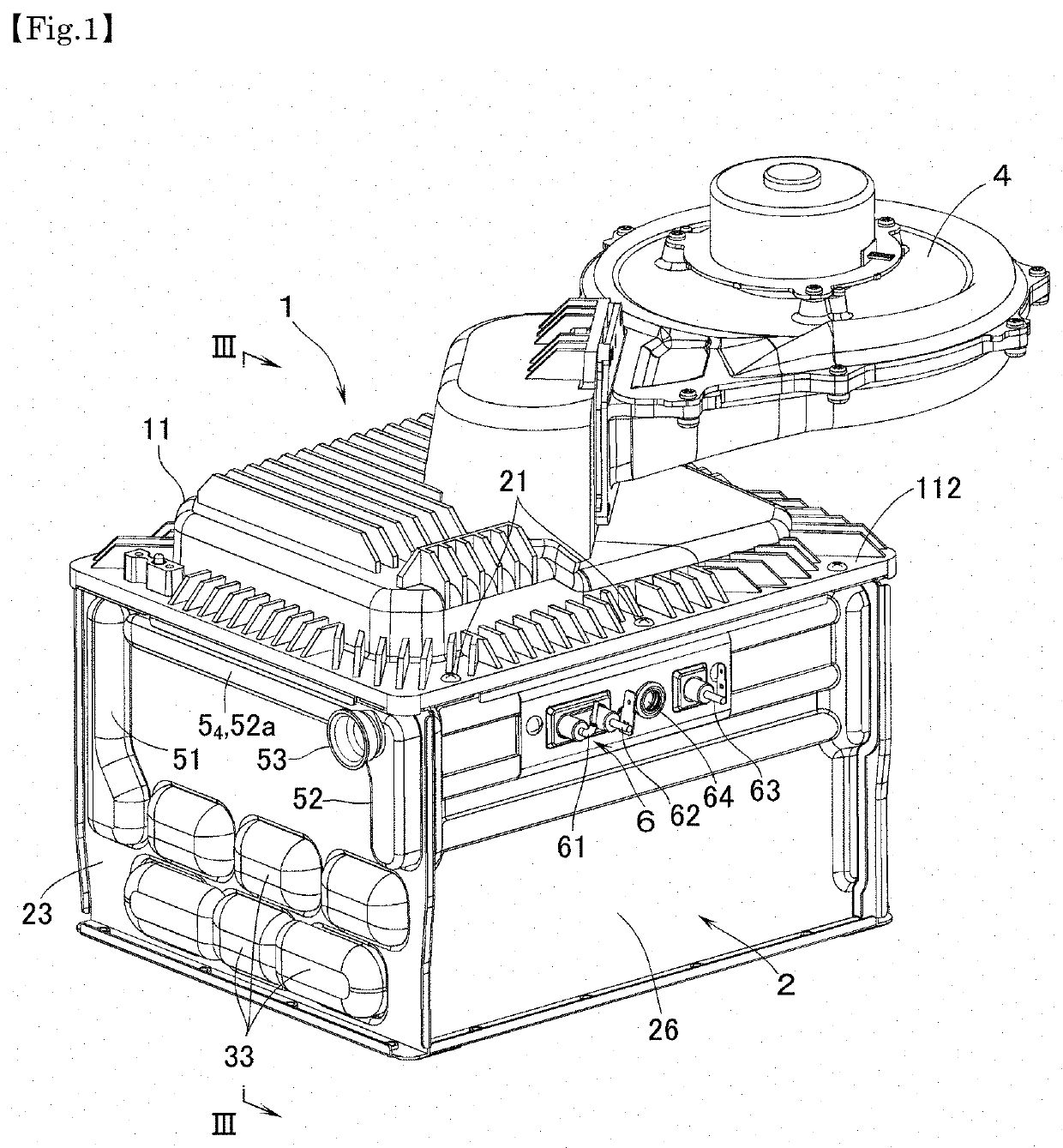

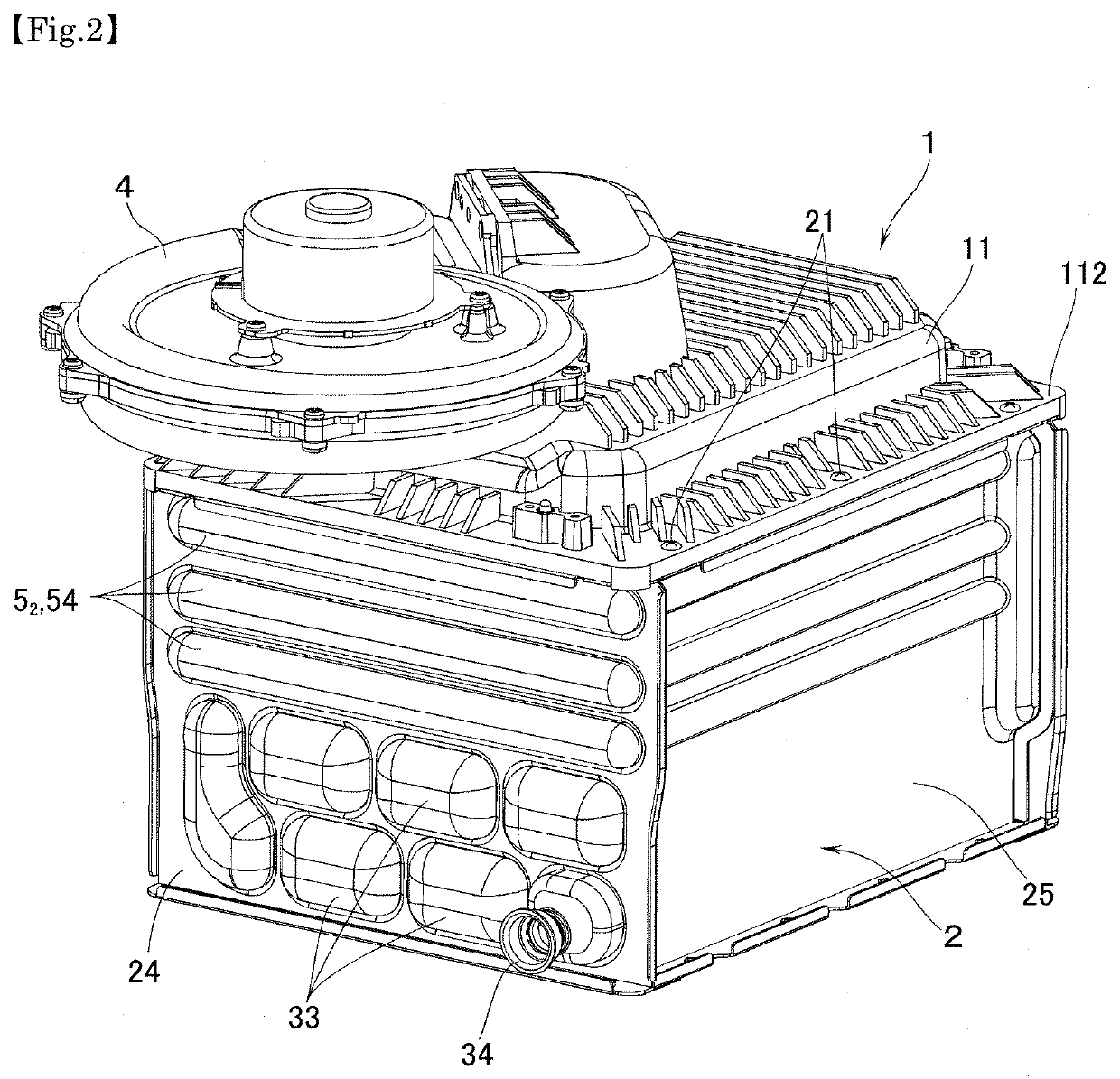

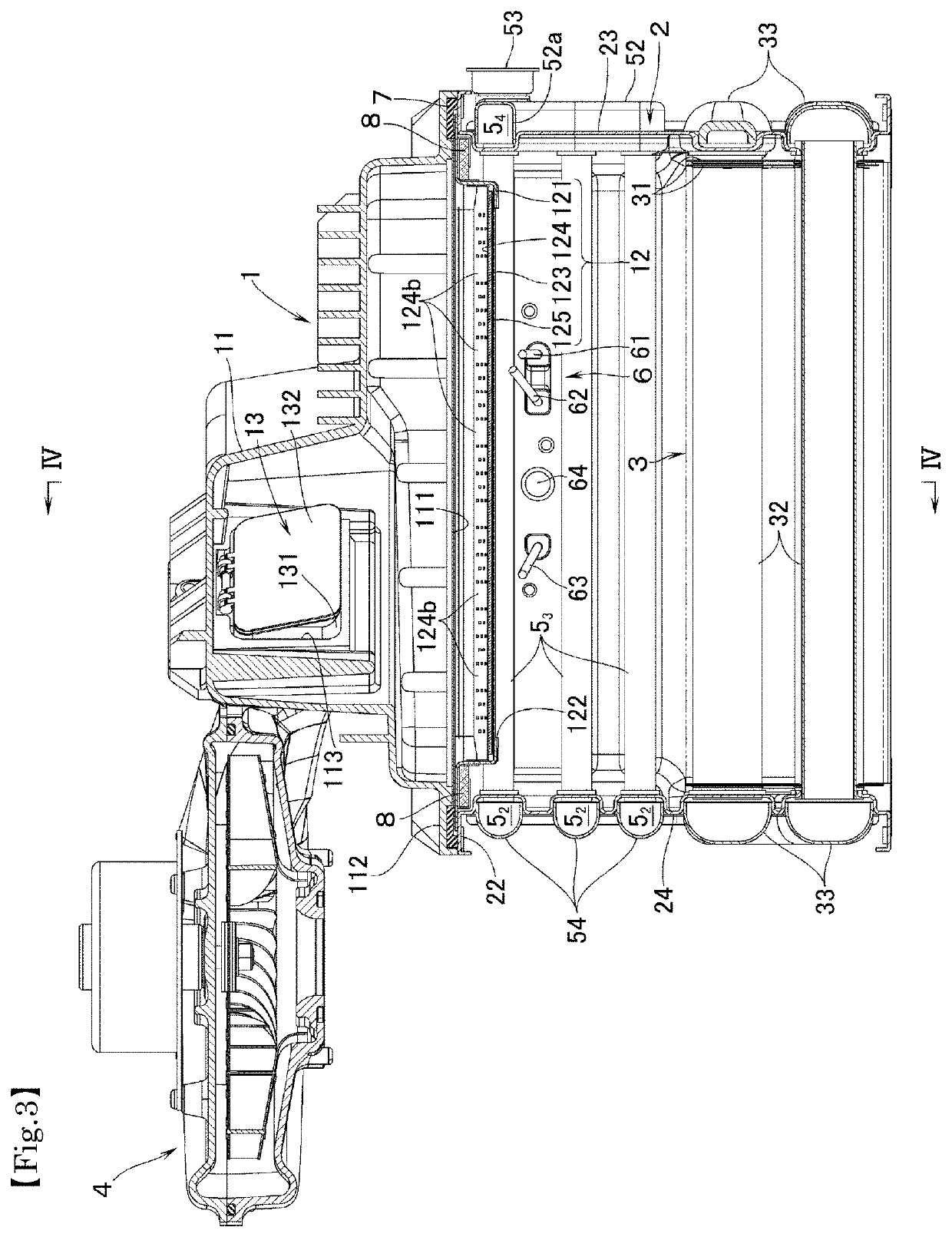

[0017]A combustion apparatus shown in FIGS. 1 through 4 is provided with: a totally aerated combustion burner 1 having a burner body 11 which is supplied inside thereof with air-fuel mixture (mixture gas of fuel gas and primary air), and a combustion plate part 12 which covers a downward open surface 111 of the burner body 11; and a combustion box 2 having a box flange part 22 at an upper end thereof which is fastened with screws 21 to the body flange part 112 enclosing the open surface of the burner body 11. The combustion box 2 has housed therein a heat exchanger 3 for hot water supply.

[0018]The heat exchanger 3 is constituted by a fin-tube type of heat exchanger provided with a multiplicity of fins 31 and a plurality of heat-absorbing tubes 32 which penetrate these fins 31. On an outside surface of side plates 23, 24 on laterally one side and the opposite side of the combustion box 2, there are connected a plurality of connection covers 33 which define connection passages of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com