Flooring system, a panel and methods of use thereof

a technology of floor covering and load bearing, applied in the field of floor covering system, can solve the problems of time-consuming, laborious and labor-intensive, and costly repairs of building elements, and achieve the effects of reducing labor intensity, time-consuming and labor-intensive, and reducing the cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

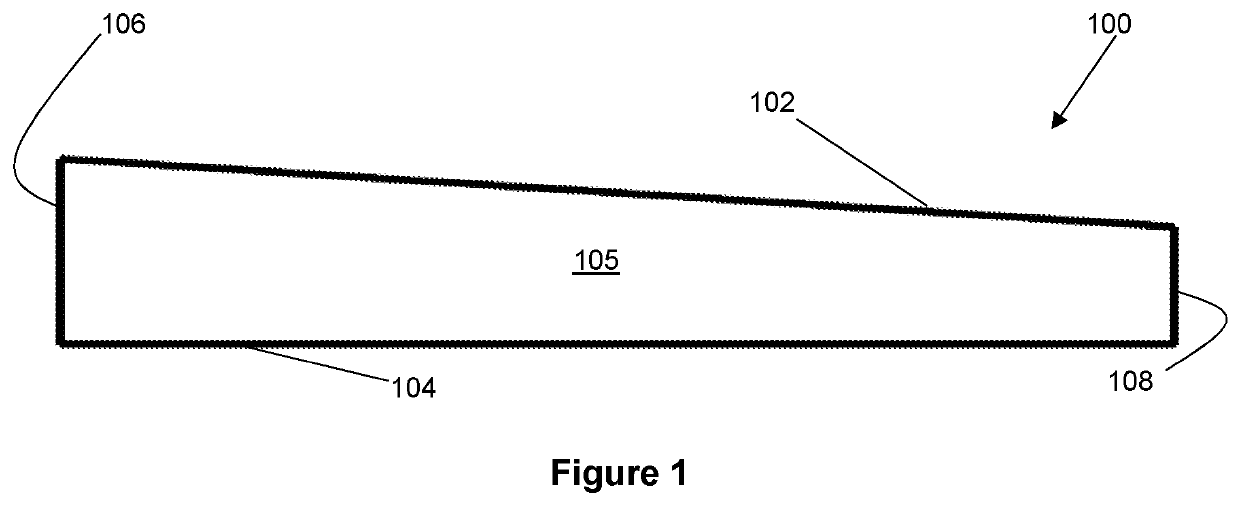

[0158]FIG. 1 shows a floor panel (100) according to an embodiment of the present invention.

[0159]The floor panel (100) has an upper surface (102), an opposed lower surface (104), opposed side edges (105) and opposed end edges, including a first end edge (106) and an opposed second end edge (108). The panel (100) tapers in thickness from the first end edge (106) to the second end edge (108) with a gradient of at least 0.1%. The gradient is a negative gradient configured to direct water or any other liquid towards the second end edge (108).

[0160]The floor panel (100) has a rectangular or square shape and is formed from concrete or plastic material and / or materials.

[0161]The panel (100) is provided in standard lengths of 1,800 mm, 2,100 mm, 2,400 mm, 2,700 mm, 3,000 mm or 4,000 mm extending between the opposed end edges (106, 108), and standard widths of 600 mm, 900 mm, 1,200 mm, 1,350 mm or 1,500 mm extending between the opposed side edges (105).

[0162]Likewise, the panel (100) can hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com