Apparatus for Oil Flow Control

a technology of oil flow and apparatus, applied in the direction of combustion regulation, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of not addressing the problem of varying viscosity and its effect on atomization and flame quality, requiring additional expenses for a viscometer and its maintenance, and too much or too little combustion air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

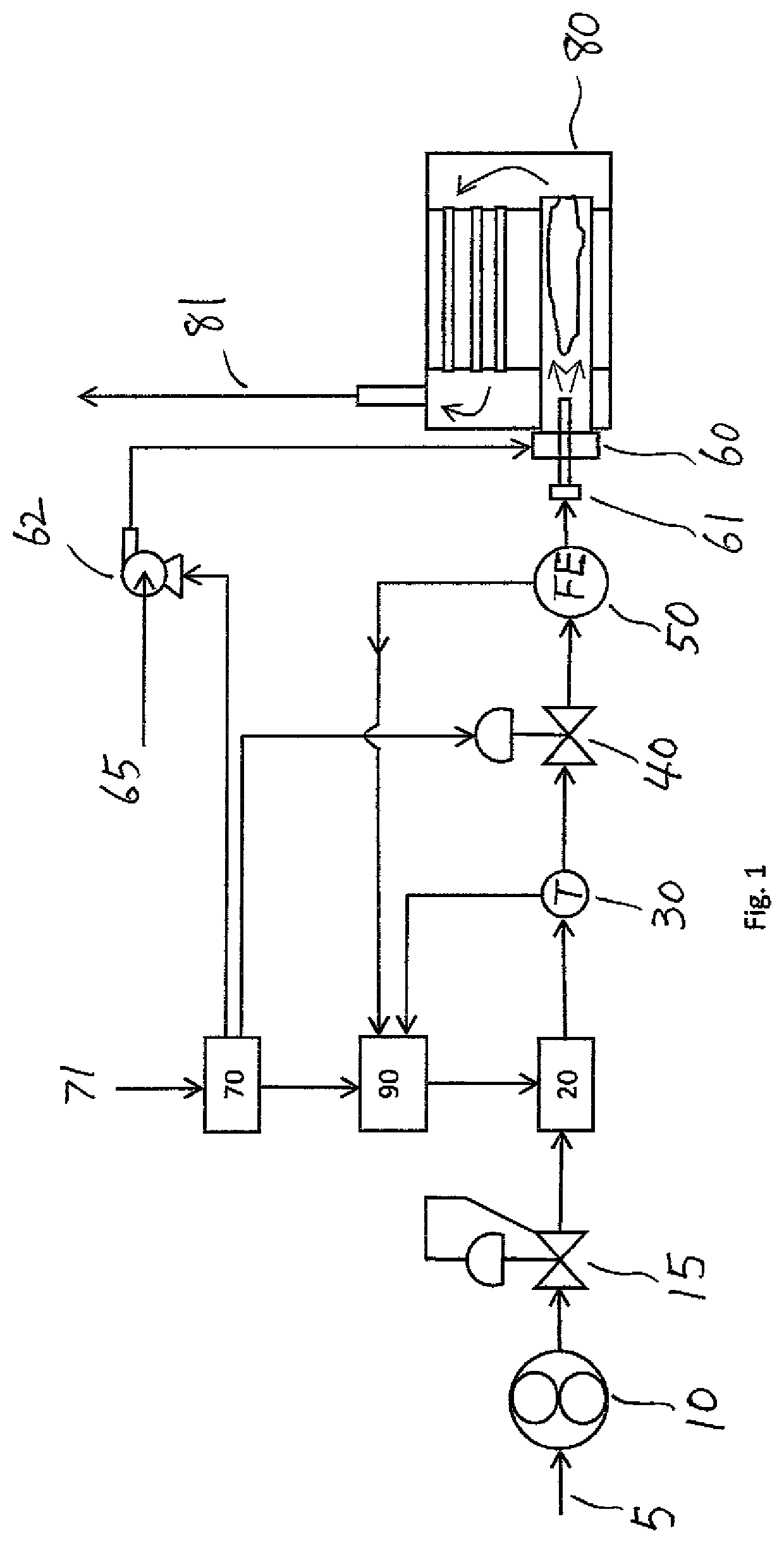

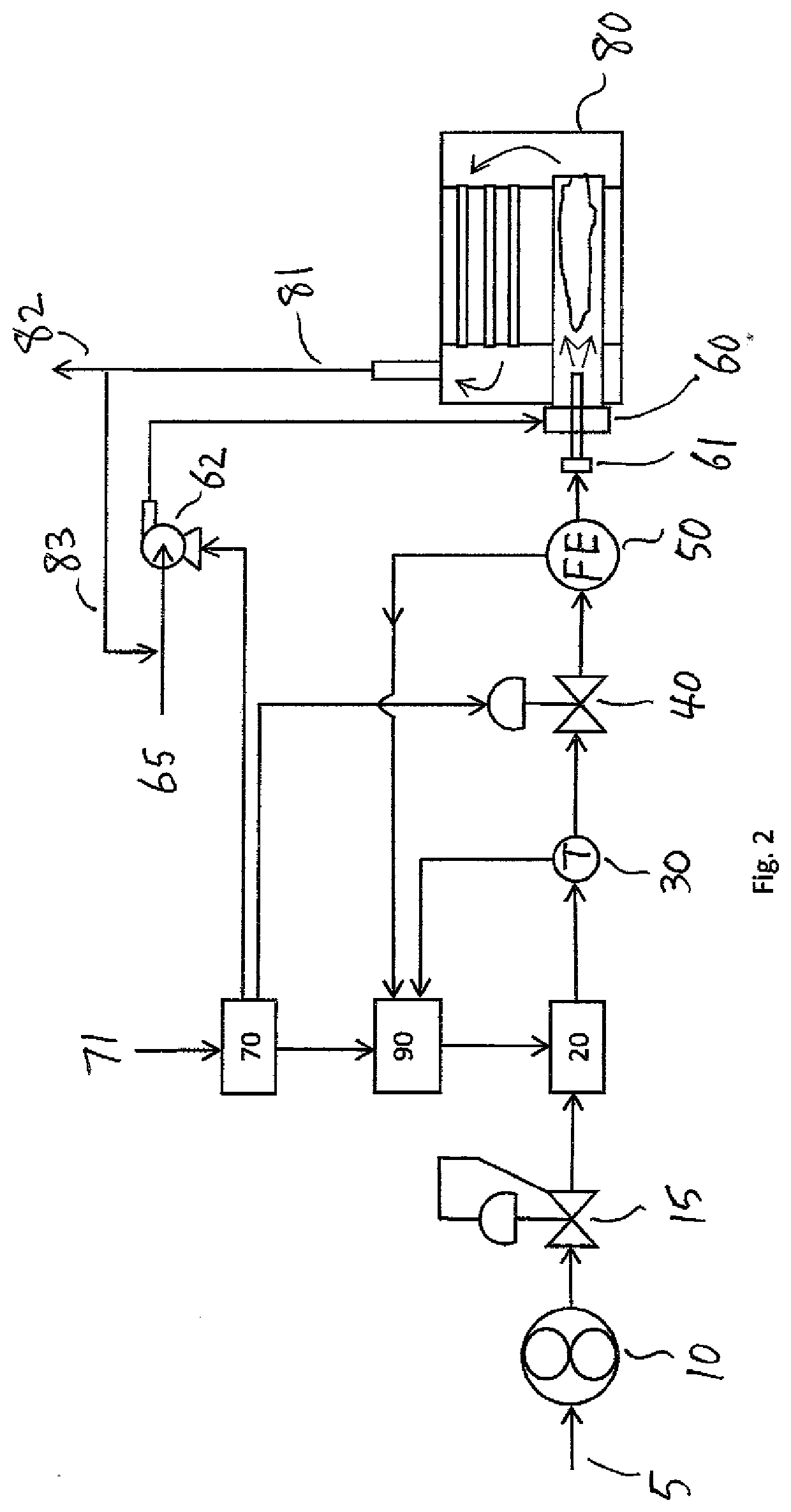

[0010]FIG. 1 is a diagram of an embodiment of the hardware configuration of the control system of the current invention.

[0011]Residual fuel oil 5 is drawn by an oil pump 10 to be pressurized, and goes through a pressure regulator 15 to reach a constant pressure downstream of the regulator 15, before going through a trim heater 20. A temperature sensor 30 measures the temperature of the fuel oil 5 and provides a feedback signal to a controller 90. Fuel oil 5 then goes through a flow control valve (FCV) 40 and a flow element 50 before it passes through the oil gun 61 to be atomized and burned in a burner 60 in a boiler 80. Boiler 80 could be a firetube boiler or a water tube boiler. The burner 60 produces a hot flue gas in boiler 80. The hot flue gas goes through the boiler and exits the boiler as flue gas 81. The flow element 50 measures the flow rate of fuel oil 5 and provides a feedback signal to the controller 90.

[0012]A combustion controller 70 takes a call-for-heat signal 71, ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap