Method of manufacturing aluminum alloy and aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The accompanying drawings for illustrating exemplary embodiments of the present disclosure should be referred to in order to gain a sufficient understanding of the present disclosure, the merits thereof, and the objectives accomplished by the implementation of the present disclosure.

[0032]In the exemplary embodiments of the present disclosure, techniques well known in the art or repeated descriptions may be reduced or omitted to avoid obscuring appreciation of the disclosure by a person of ordinary skill in the art.

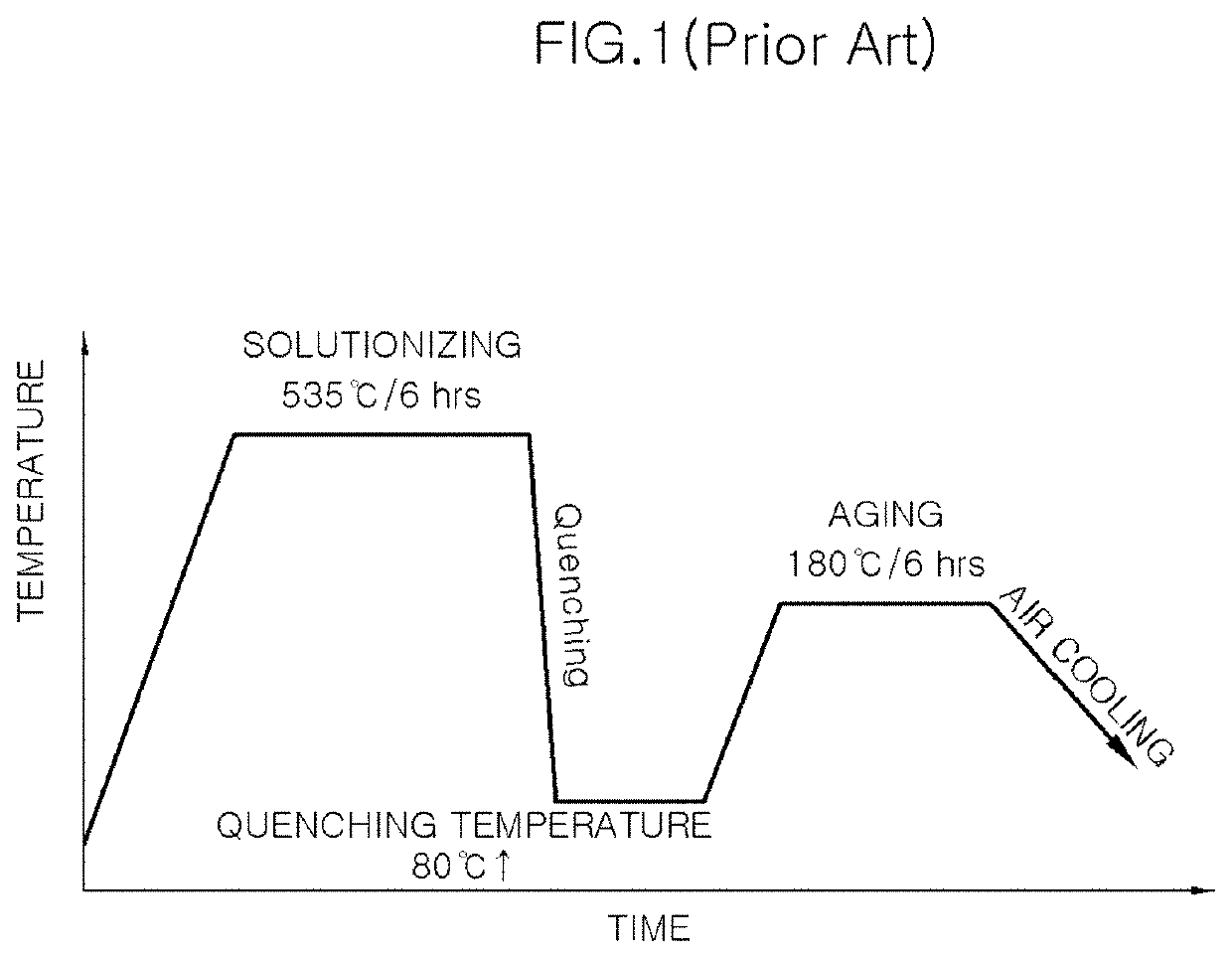

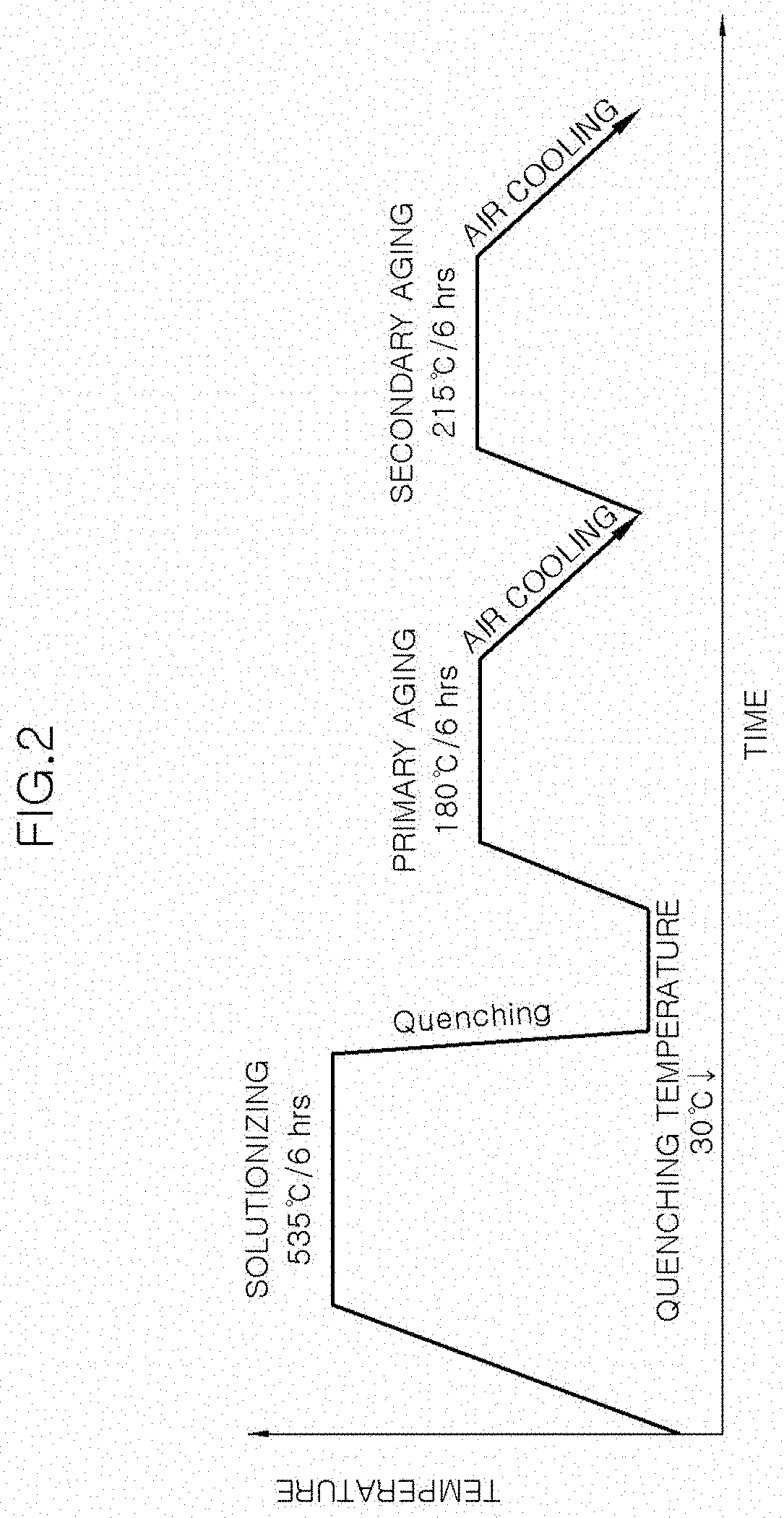

[0033]FIG. 2 illustrates a heat treatment process of an alloy for cylinder heads according to an embodiment of the present disclosure.

[0034]A method of manufacturing aluminum alloy and an aluminum alloy produced thereby according to exemplary embodiments of the present disclosure will be described below with reference to FIG. 2.

[0035]The present disclosure relates to a composition and manufacturing method of an alloy for cylinder heads capable of realizing high-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com