A drawer sliding system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

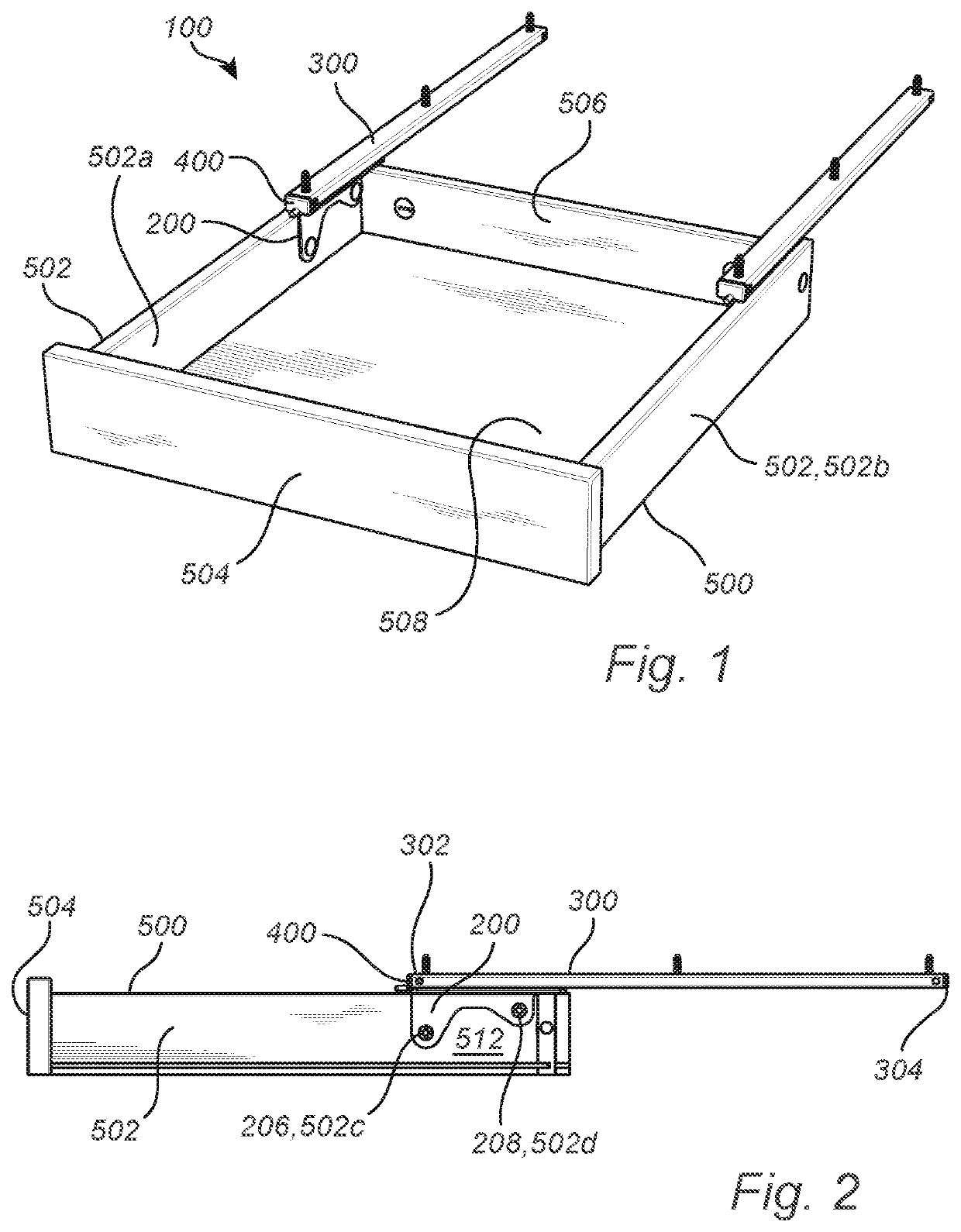

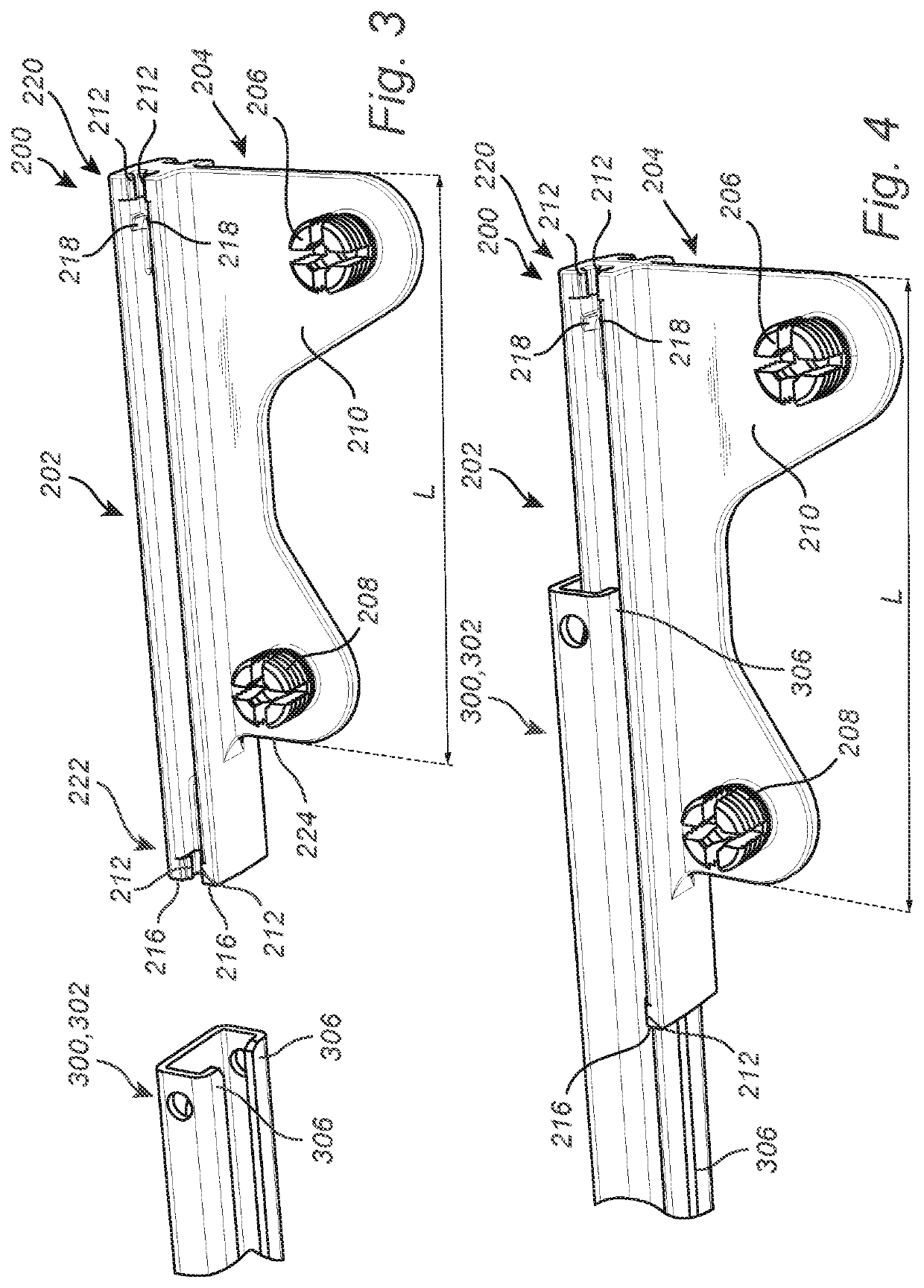

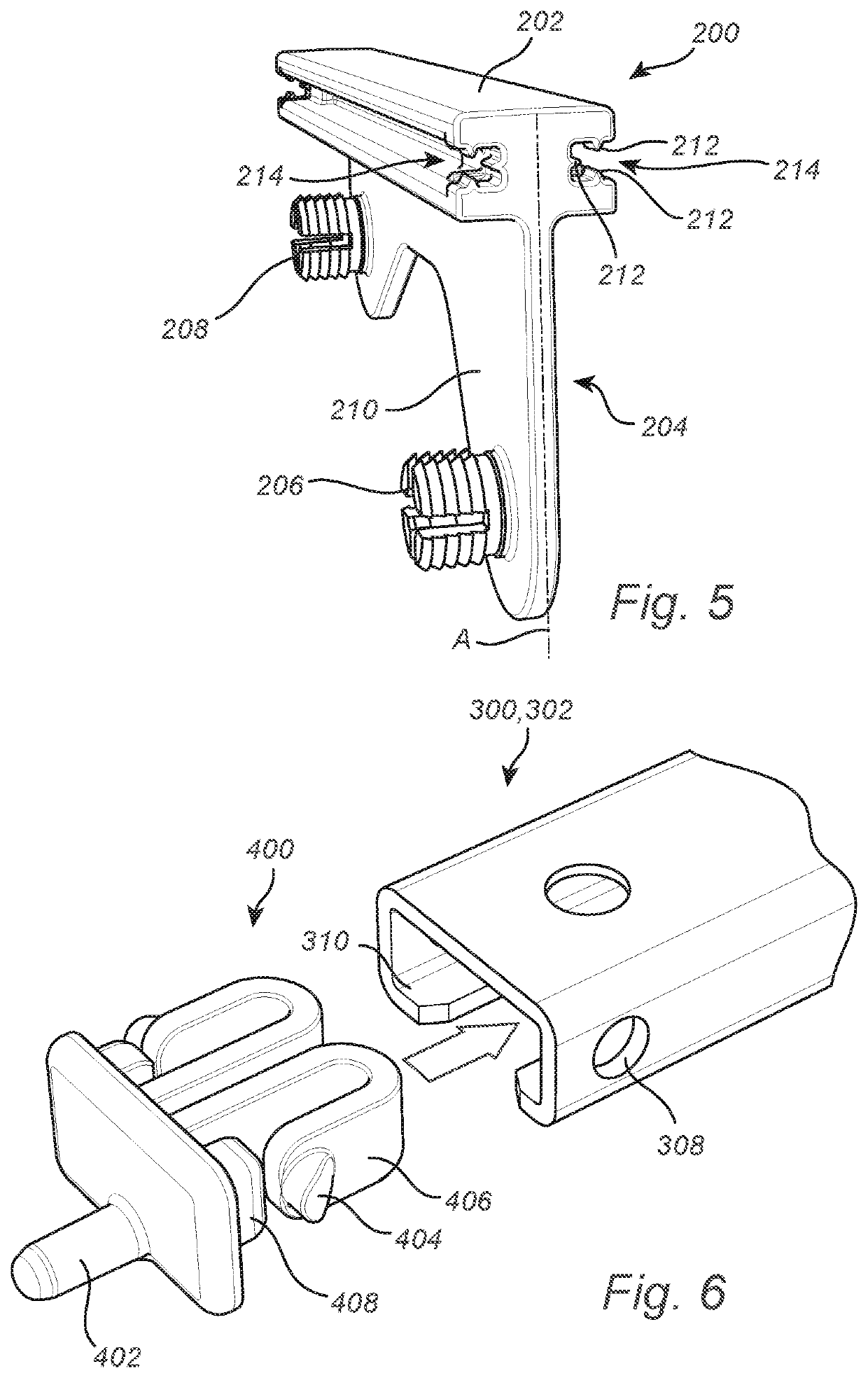

[0036]The disclosed embodiments will now be described more fully hereinafter with reference to the accompanying drawings, in which certain embodiments of the invention are shown. Like numbers refer to like elements throughout. Throughout the application is reference made to directions, such as forward, rearward etc. A forward direction in the context of this application is the direction in which the drawer 500, and all thereto attached components, moves during an opening motion. Consequently, the rearward direction is opposite the forward and thus the direction of a closing motion of the drawer 500.

[0037]FIG. 1 shows a drawer 500 comprising a drawer sliding system 100. The drawer 500 preferably comprises a front panel 504, two side panels 502, a rear panel 506 and a bottom panel 508. Typically, drawer panels are made to a large extent from wood based materials such as particle board, fibre board or solid wood. The teachings herein are however not limited to use only with furniture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com