Atomization device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

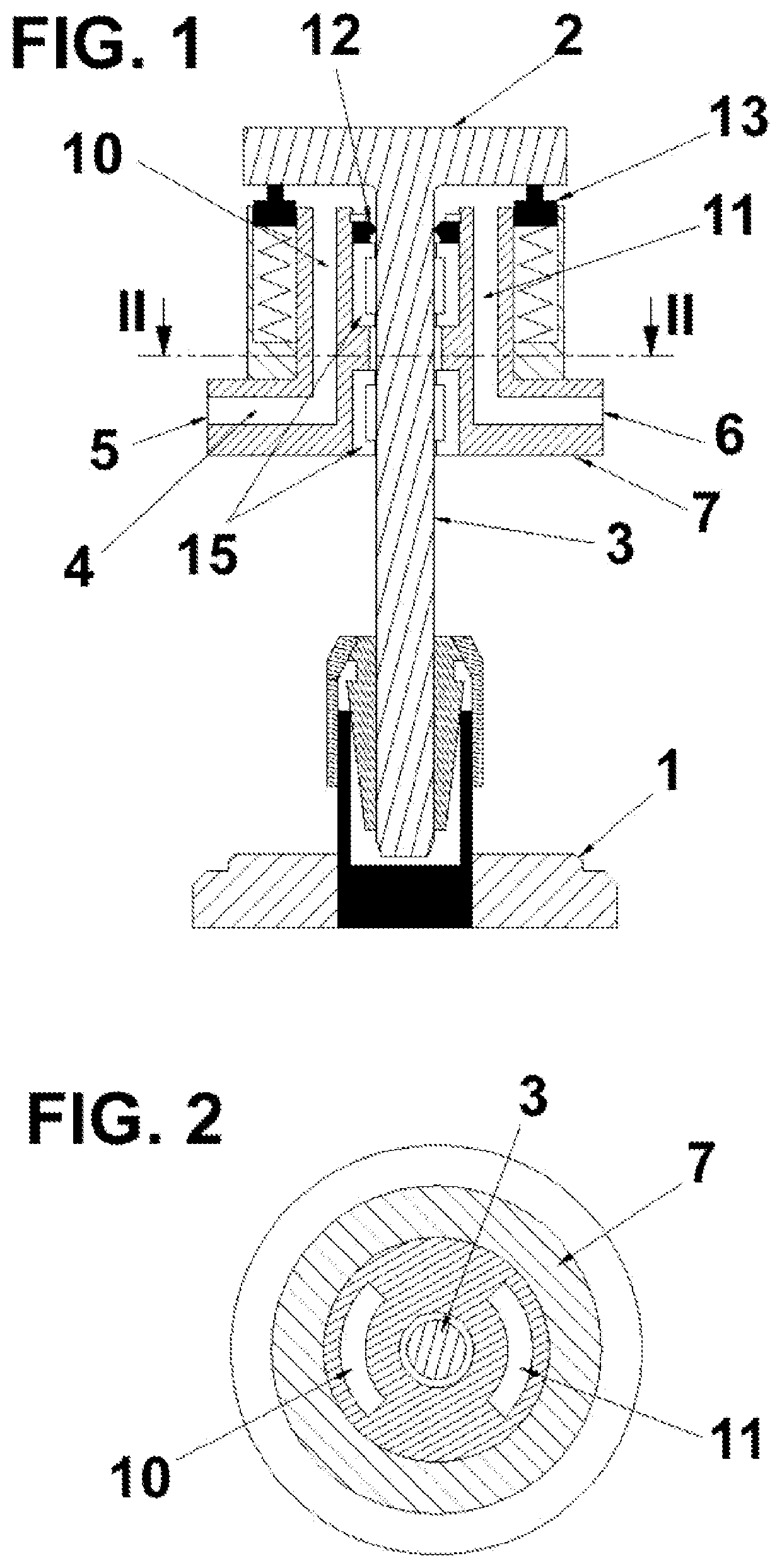

[0020]The atomization device of the invention solves the mentioned drawbacks and presents other advantages that will be described below.

[0021]The atomization device according to the present invention comprises a motor rotatably driving a spinning disc by means of a rotating shaft, and cooling means for cooling said spinning disc, wherein said cooling means comprise a cooling circuit extending around at least one portion of the rotating shaft and below at least one portion of said spinning disc.

[0022]Because the cooling circuit is not located in the actual rotating shaft, it is possible for the drive system of the disc to be simpler, enabling perfect alignment of the rotating shaft of the motor with the spinning disc. This minimizes rotating moving parts, which prevents vibrations from being produced.

[0023]According to a preferred embodiment, said cooling circuit is located in a stationary base in turn acting as a collector for the cooling circuit, comprising at least one inlet and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com