Compact valve actuation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

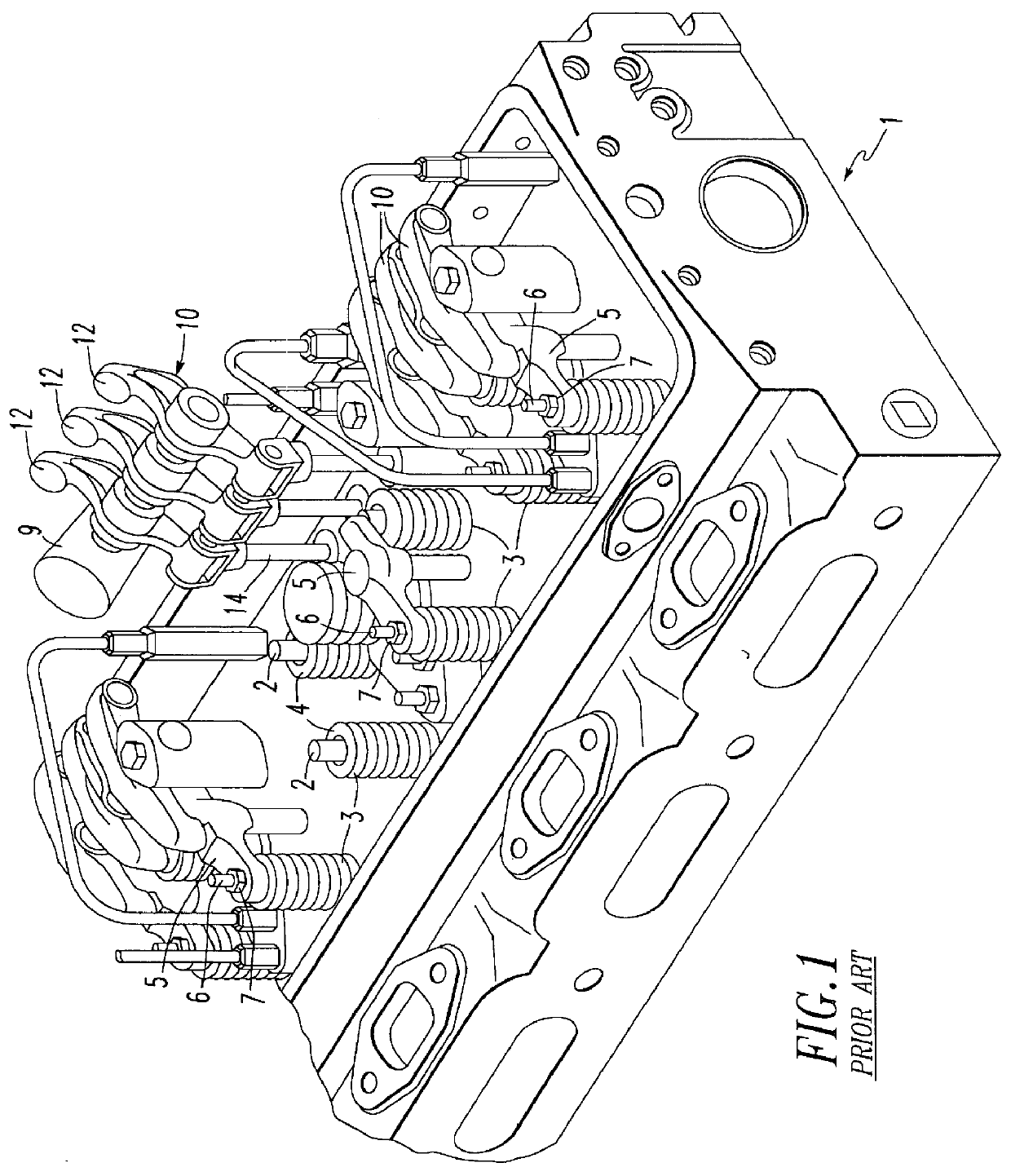

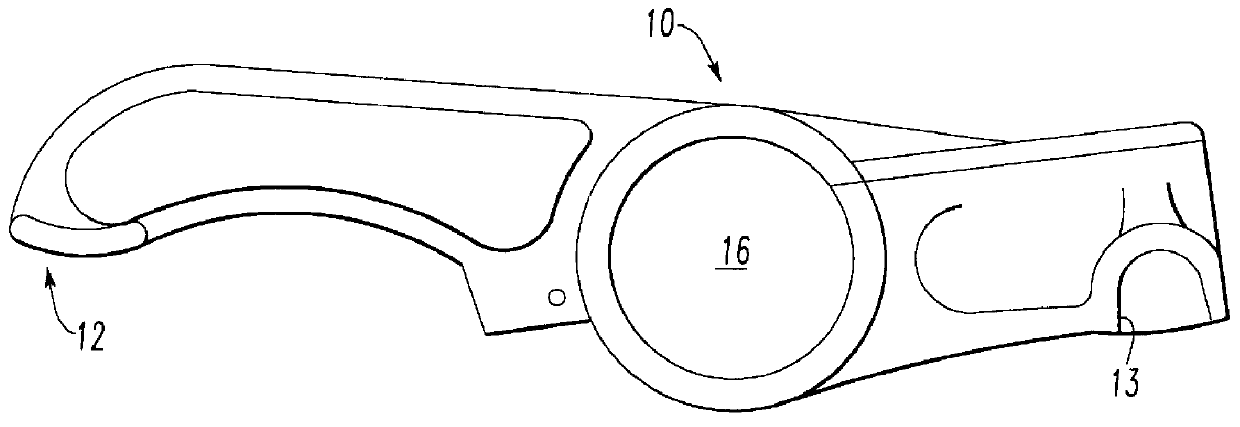

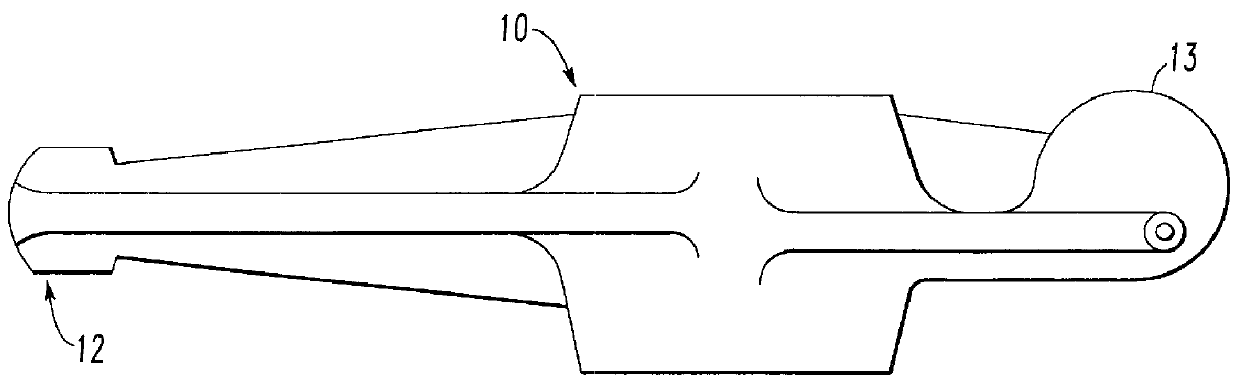

Referring now to the drawings for the purposes of illustrating present embodiments of the invention only and not for the purposes of limiting the same, the FIGS. 4-6 show a valve actuation mechanism 18 of the present invention used in connection with a piston-driven internal combustion engine 20 that has a cylinder head 22 with a total of four cylinders 24 therein. While the present invention is particularly well-suited for actuating the intake or exhaust valves of a piston-driven internal combustion engine 20, one of ordinary skill in the art will appreciate that the unique valve bridge and rocker arm embodiments of the present invention disclosed herein could be successfully employed in myriad of other applications in which the actuation of valves of varying types is required. Accordingly, the protection afforded to the present preferred embodiments disclosed and claimed herein should not be limited solely to use in connection with the engine 20 of the type depicted in the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com