Stripline coupling structure for high power HTS filters of the split resonator type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A resonator which is interfaced by an I / O coupling can be of a sliced resonator type. The feed line is inserted into the resonator in one of resonator gaps as shown in FIG. 6. By adjusting the depth of penetration and spacing between the feed line and resonator, a wide range of coupling values can be achieved. Since it is a smooth line configuration, no high current concentration exists due to discontinuities. The possibility of arcing is significantly reduced because of much wider spacing between the inserted line and resonator than with previous devices.

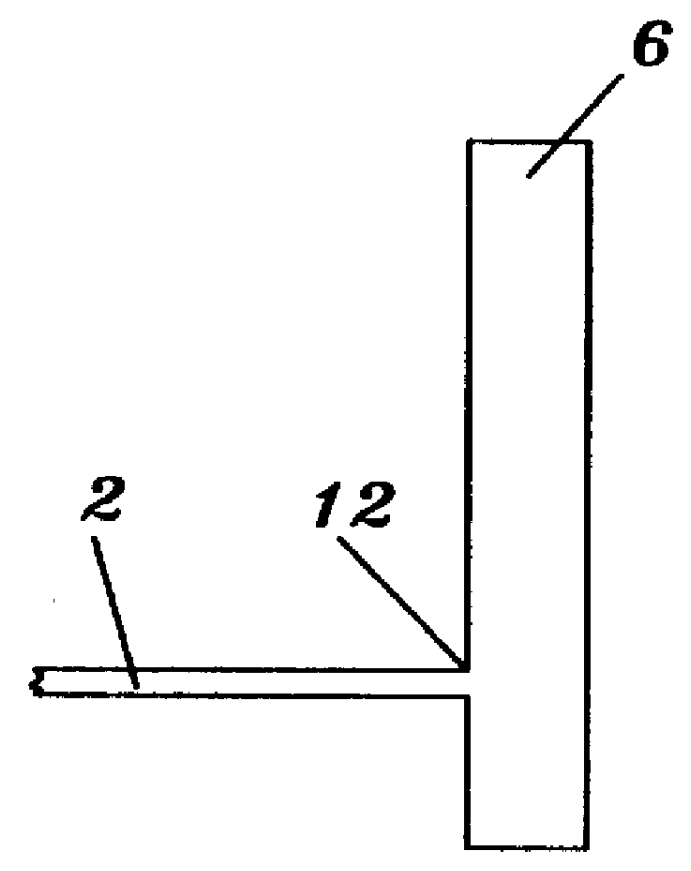

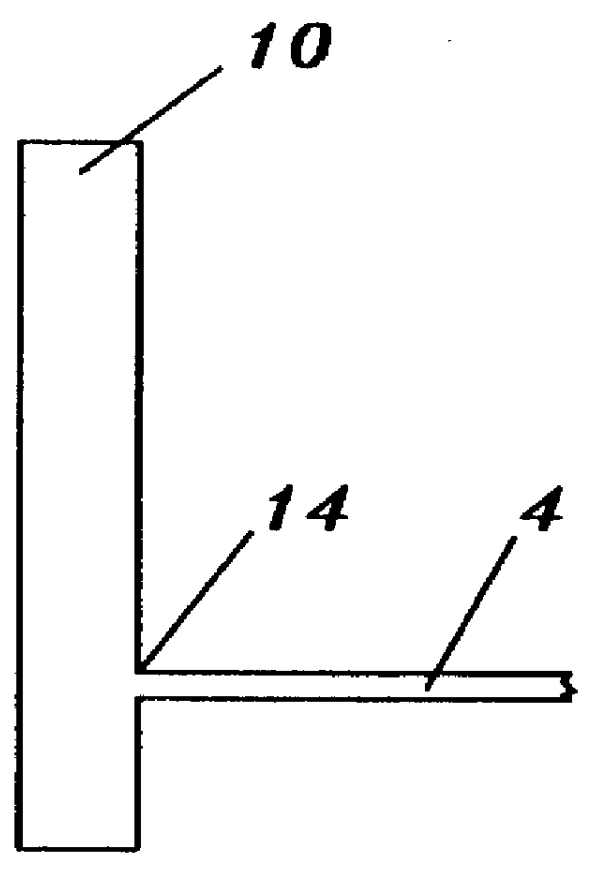

In FIG. 1, a prior art microstrip filter has feed lines 2, 4. There are three resonators 6, 8 and 10. Feed line 2 is in direct contact at point 12 to resonator 6. Feed line 4 is in direct contact at point 14 to resonator 10.

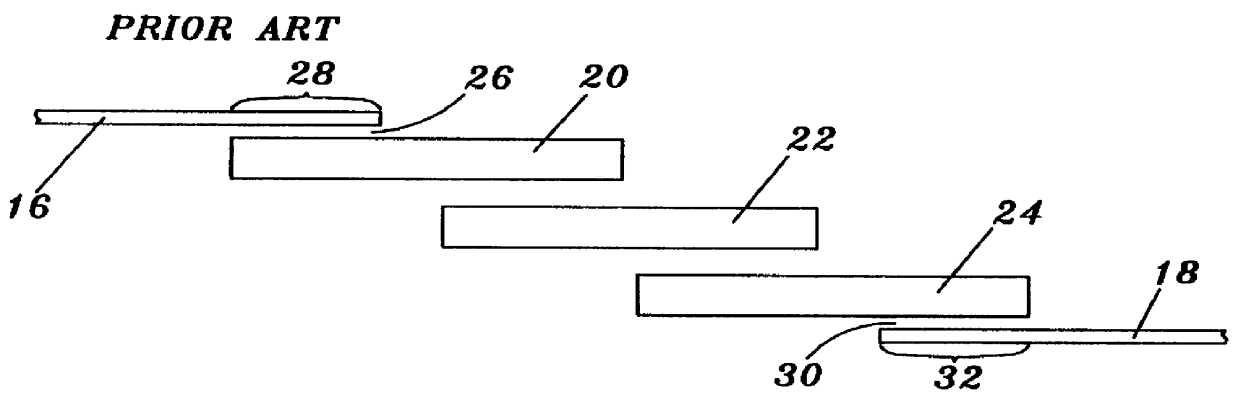

In FIG. 2, a prior art microstrip filter is shown with feed lines 16, 18 and resonators 20, 22 and 24. A gap 26 separates parallel section 28 of the feed line 16 from the resonator 20. Similarly, a gap 30 separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com