Method and apparatus for assembly of stair forms

a technology for stair forms and apparatuses, applied in the field of construction forms, can solve the problems of time-consuming and wasteful methods for creating stair forms, concrete work notoriously messy, and the back surface of the apparatus is not well oriented, so as to achieve the effect of time-consuming and wasteful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

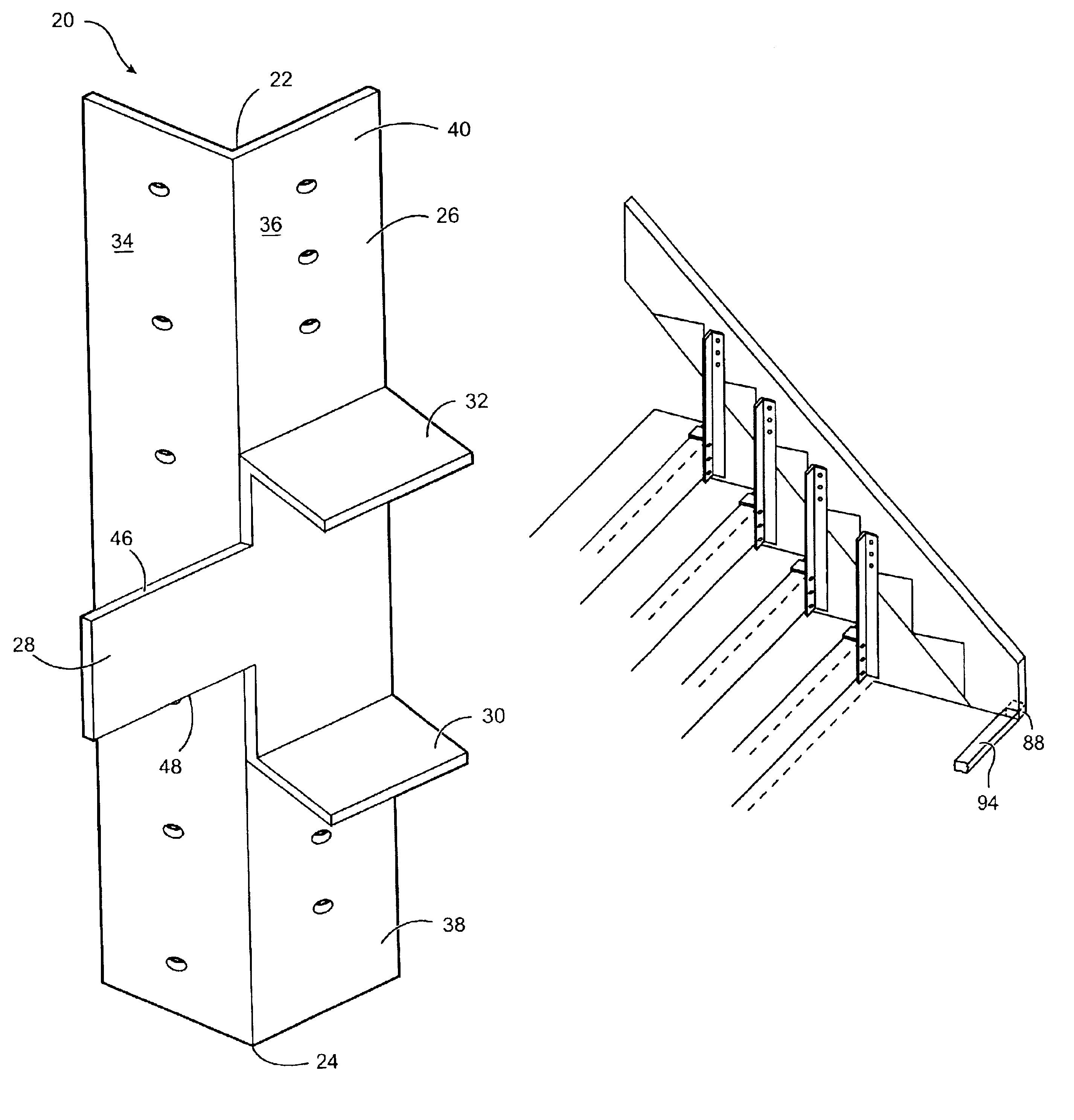

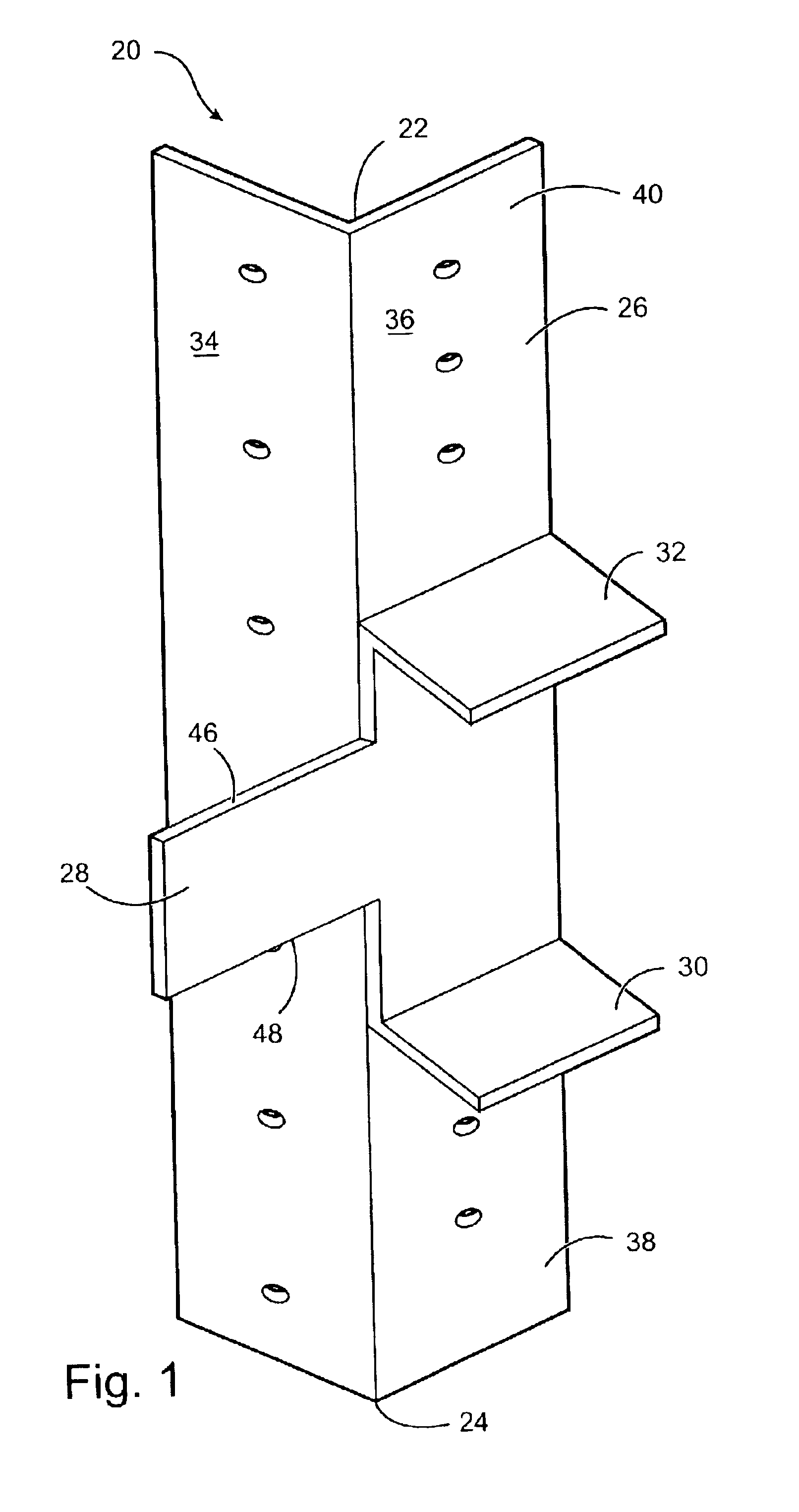

Referring now to the drawings, FIG. 1 shows an apparatus 20 according to the present invention. The apparatus has a first end 22 opposite a second end 24 of a bracket 26. The apparatus includes the bracket 26, a stringer stop 28, and at least a first riser stop 30. The apparatus may also include a second riser stop 32.

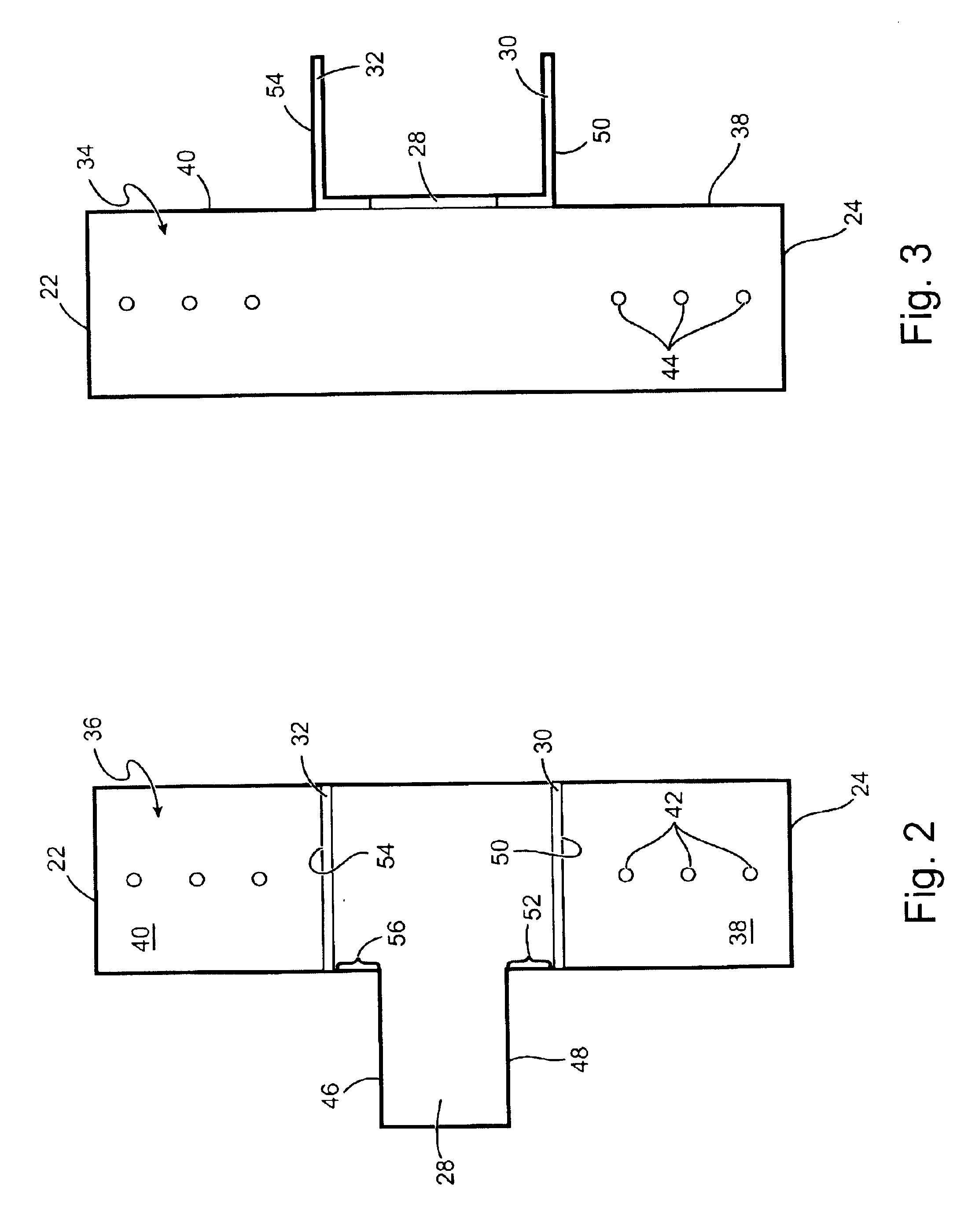

The bracket 26 has a stringer mount face 34 and a riser mount face 36. The riser mount face includes a first mounting region 38 and a second riser mounting region 40. The stringer mount face and the riser mount face extend longitudinally between the first end 22 and the second end 24. At least a portion of the stringer mount face defines a stringer mount plane and at least a portion of the riser mount face defines a riser mount plane. The bracket is configured such that the stringer mount plane is generally perpendicular to the riser mount plane.

Referring now to FIGS. 2-3 (a side and front plan view respectively of the apparatus of FIG. 1), the riser mount face 36 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| floor elevation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com