Variable stiffness coil for vasoocclusive devices

a vasoocclusive coil and variable stiffness technology, applied in the field of implantable devices, to achieve the effect of variable stiffness, variable stiffness, and variable stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

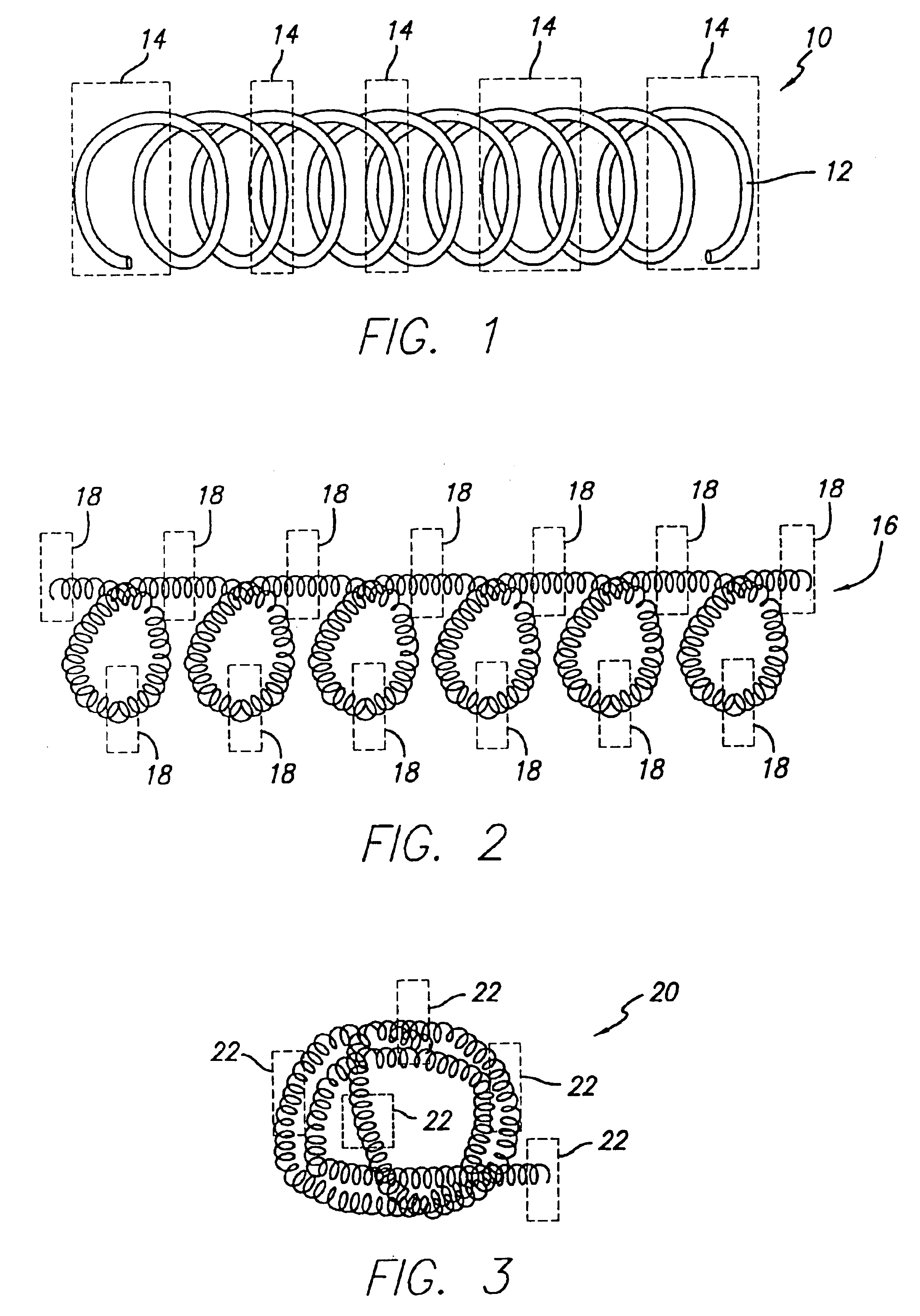

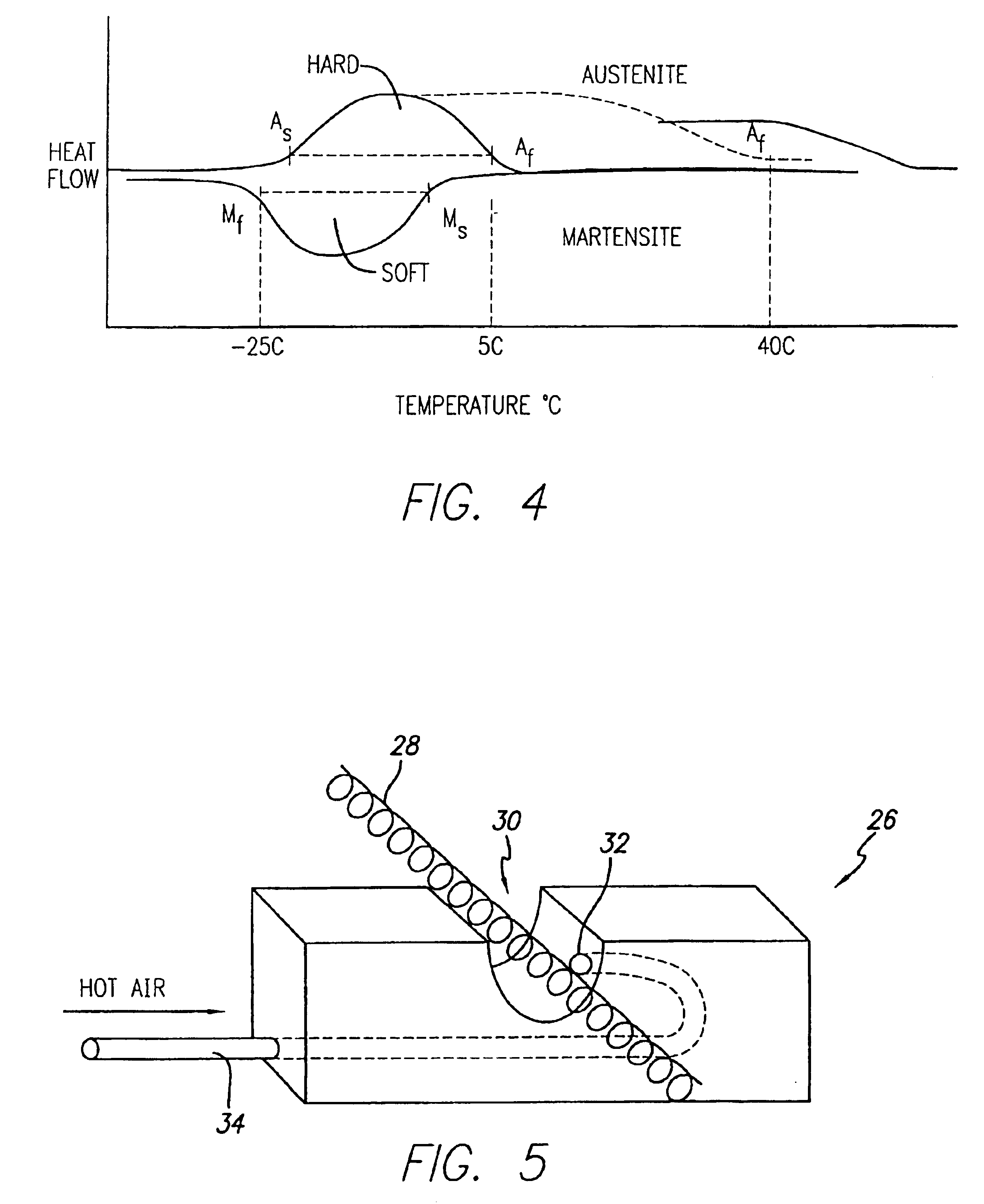

Modem techniques for filling wide neck aneurysms typically involve breaking a coil or permanently deforming a coil within a vessel utilizing a balloon, with attendant substantial risks to a patient, and a coil which has soft or deformable segments may offer less risk to a patient. While modern vasoocclusive coils deform and set their shape when they are introduced into a vessel, over time such coils will typically assume their original shape rather than to the shape of the vessel being filled. Filling of a variety of types of aneurysms of various sizes and shapes may benefit by use of a variable stiffness coil that can deform more readily at certain predetermined sections to fill an aneurysm more evenly and completely over long periods of time.

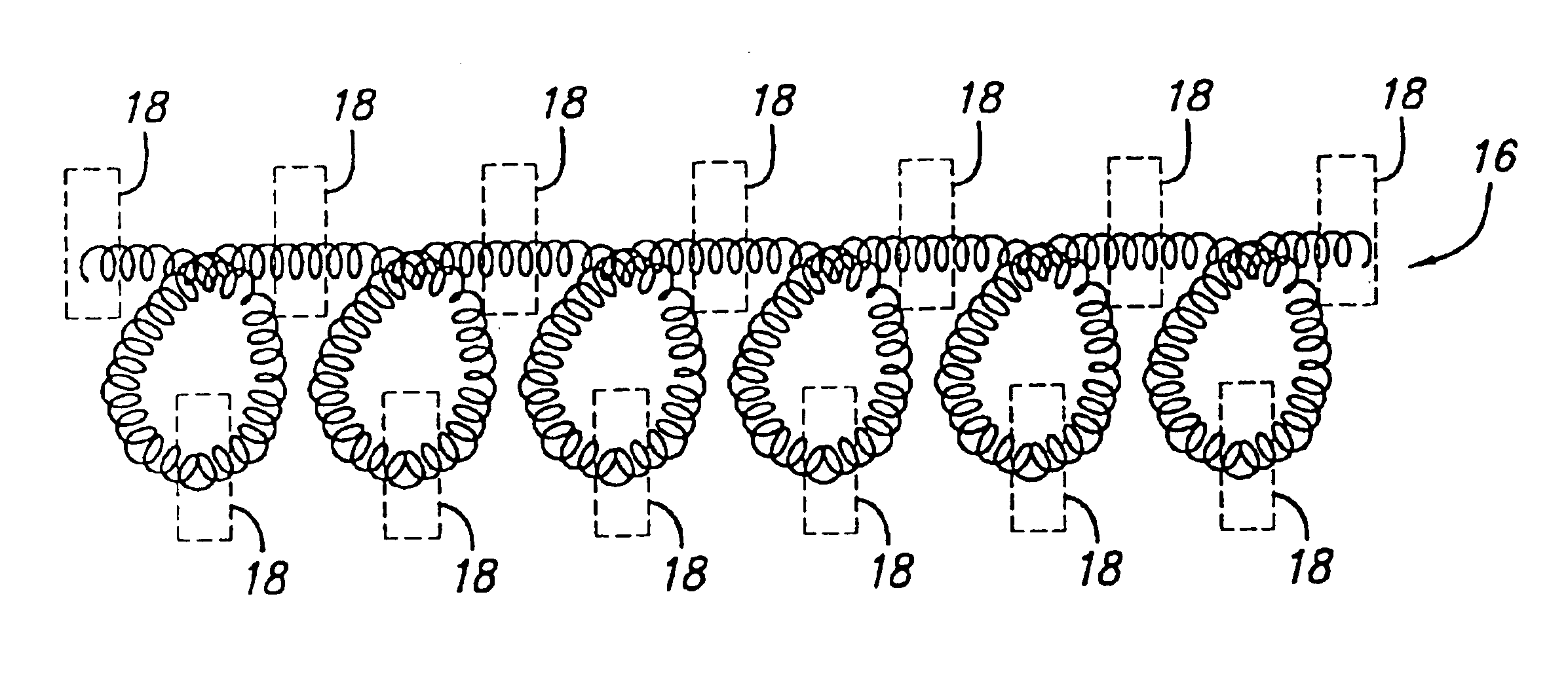

As is illustrated in the drawings, the invention is embodied in an occlusive device for use in interventional therapy and vascular surgery adapted to be inserted into a portion of a vasculature for occluding a selected portion of the vasculatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com