Fiber optic sensor for precision 3-D position measurement

a fiber optic sensor and position measurement technology, applied in the field of optical fiber-based sensors, to achieve the effect of accurate measurement of local curvature and torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

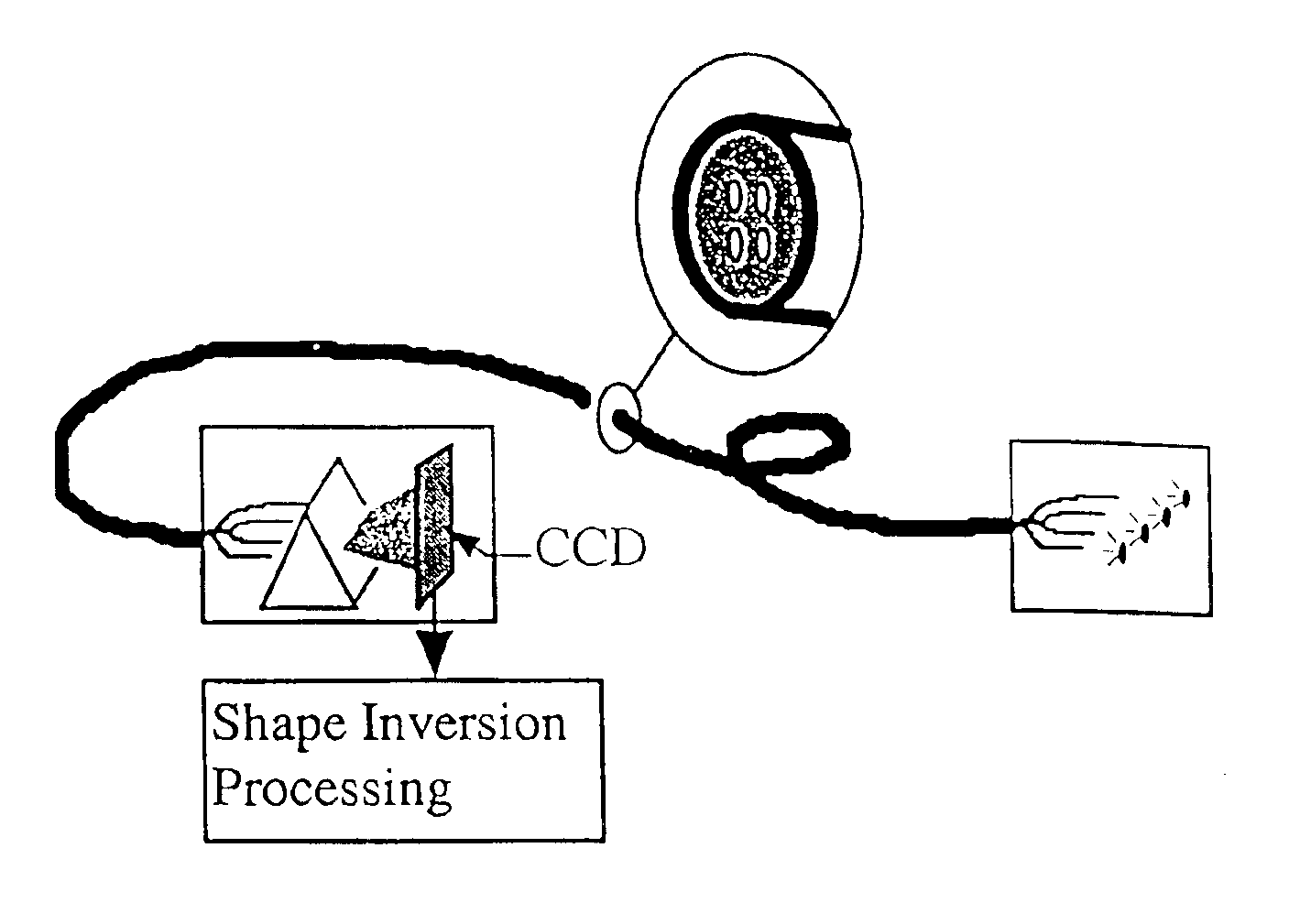

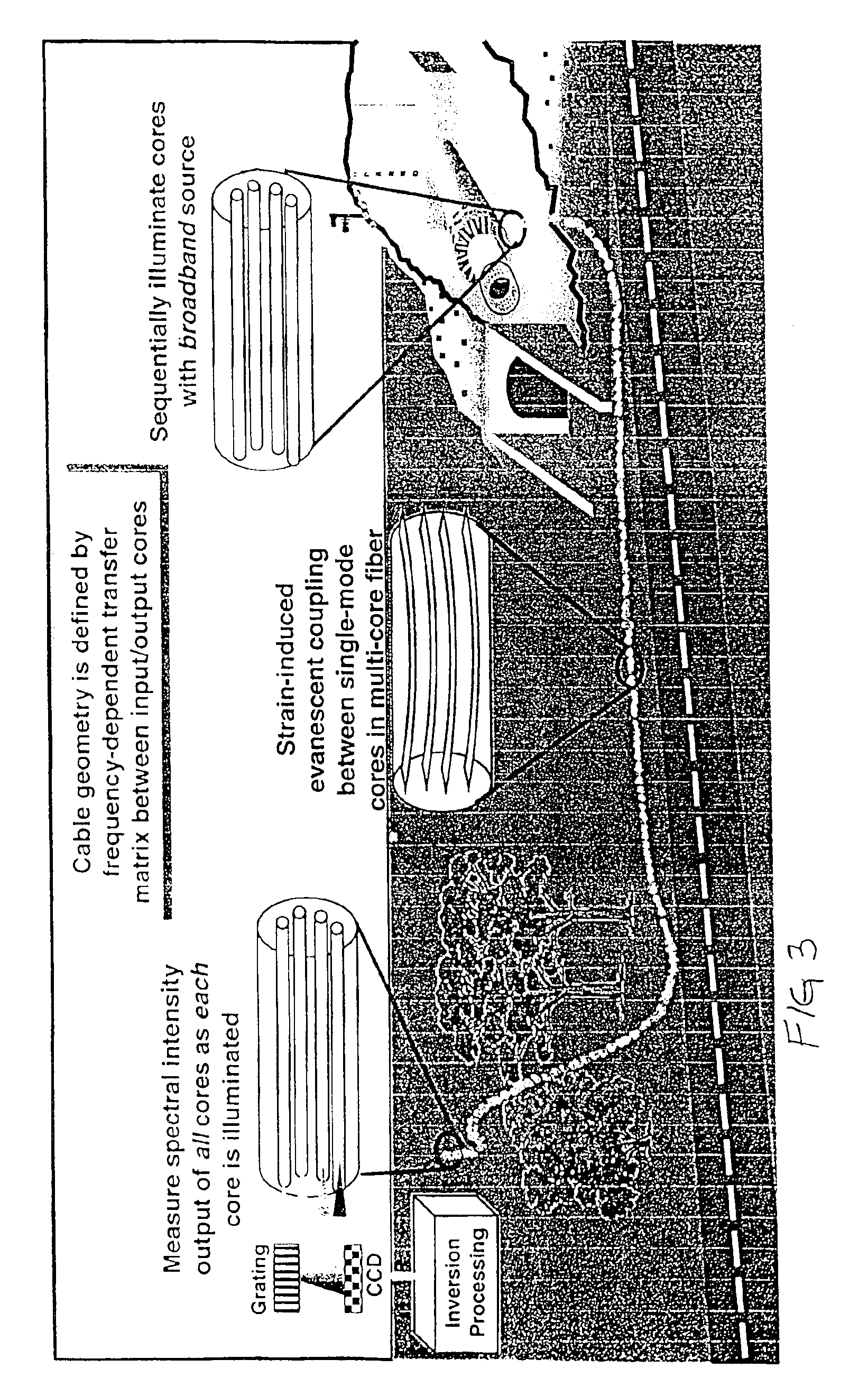

[0019]FIG. 1 is a sketch of the preferred embodiment of the invention. At one end of the fiber, the cores are illuminated sequentially by a broadband source and at the other end, the output intensities are resolved spectrally with a grating or prism and sensed with a CCD. The system is described by a frequency-dependent transfer matrix relating input to output core intensities. In general this transfer matrix is a strongly nonlinear function of the cable shape. A shape inversion algorithm which can cope with this nonlinearity is used to define the precise shape of the fiber cable.

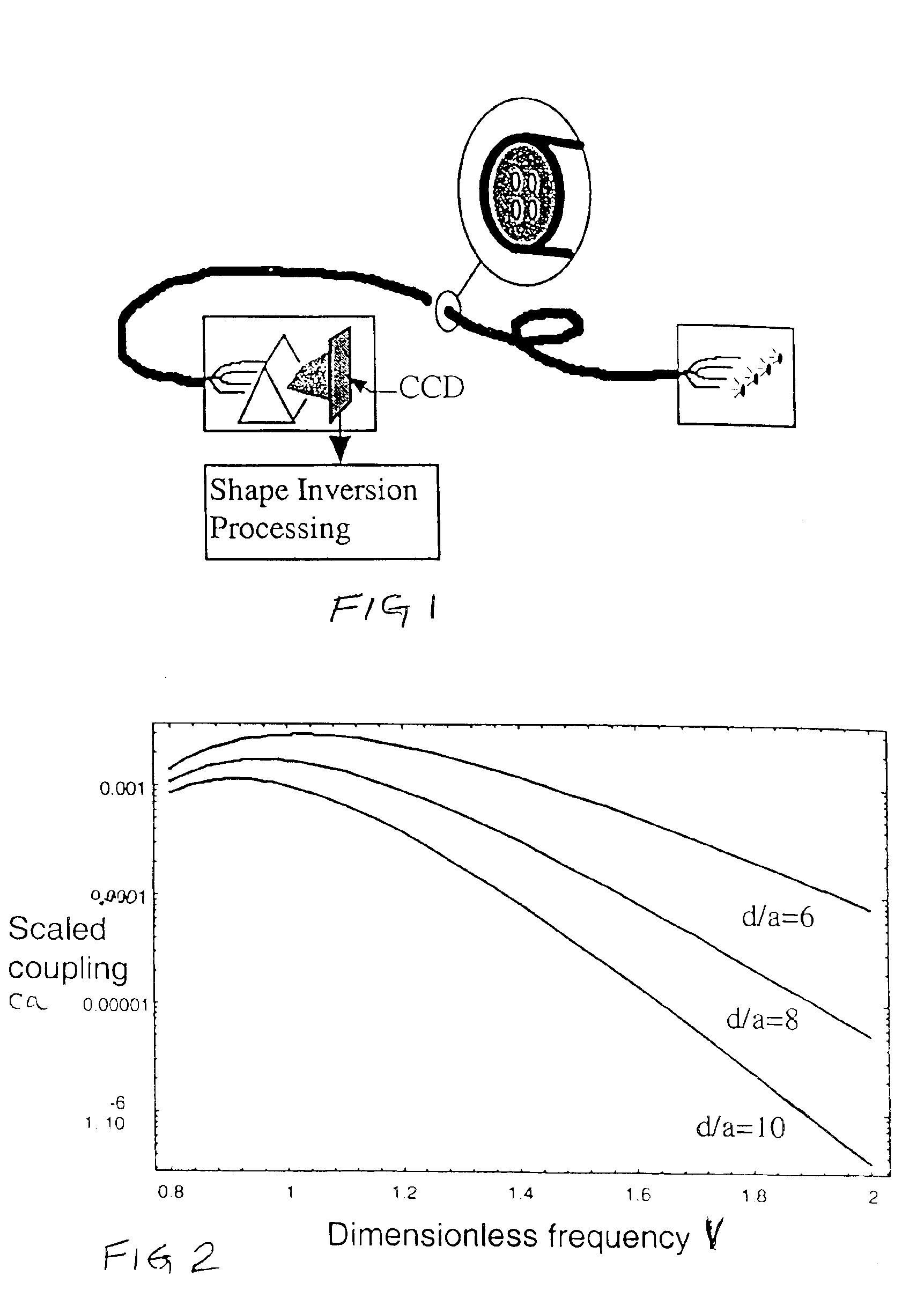

[0020]In general terms, the invention may have various embodiments which take into account the following:[0021]1. The relation between local fiber curvature and torsion and intercore mode coupling (cross-talk).[0022]2. The shape inversion algorithm which functions over a useful range of cable configurations.[0023]3. The minimum number of fiber cores required in principle to reconstruct cable shape from inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectral intensities | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| spectral intensity measurement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com