Light source substrate

a technology of light source and substrate, which is applied in the direction of lighting support devices, instruments, lighting and heating apparatus, etc., can solve the problems of not meeting the current requirements for lightness and thinness, conventional display devices occupying a certain degree of volume, etc., to improve uniformity and illumination of backlight modules, reduce the quantity of leds, and save time, cost and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

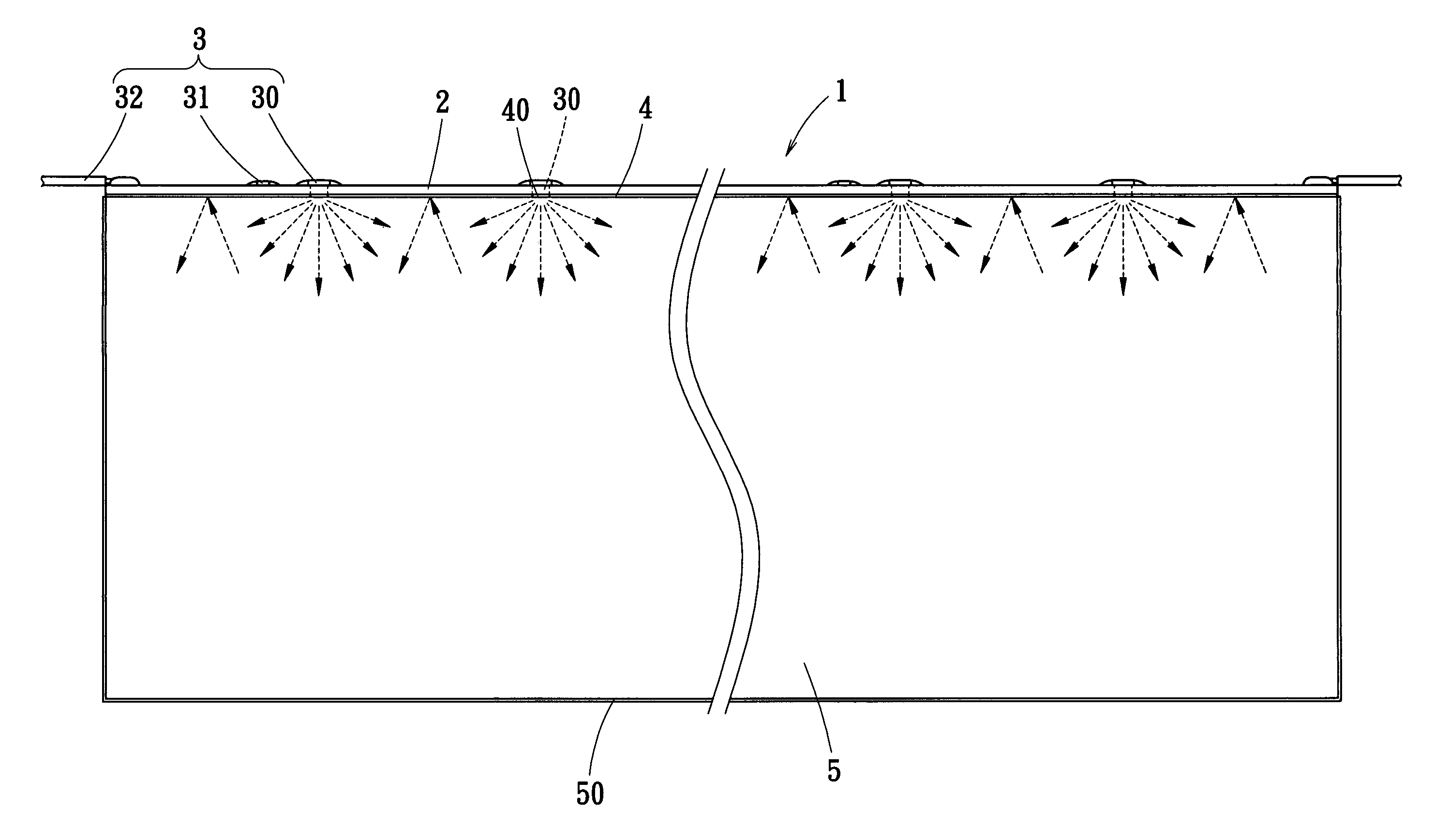

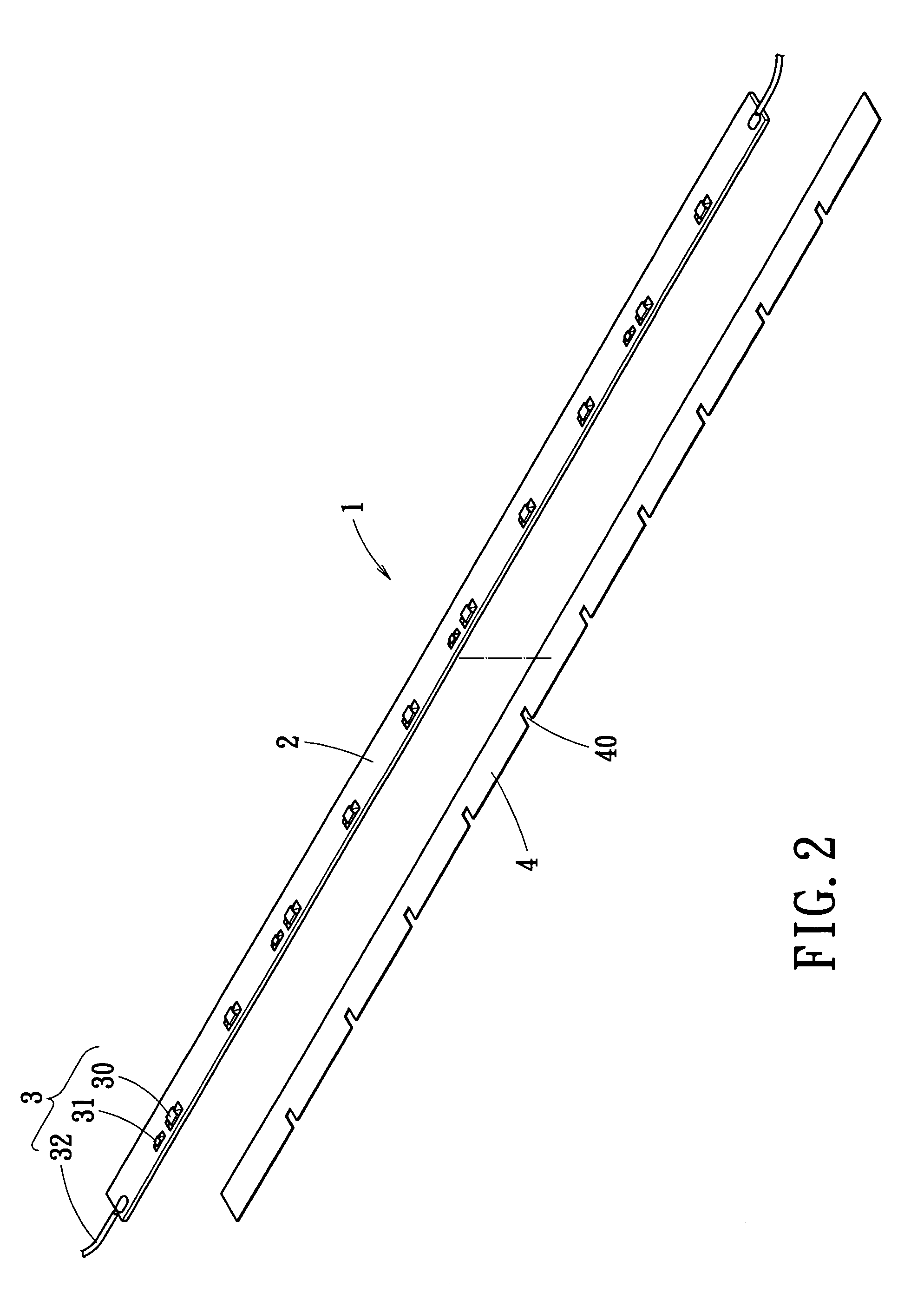

[0019]With respect to FIG. 2 to FIG. 4, the present invention provides a light source substrate 1 adopted for a backlight module including a printed circuit board 2, a lighting assembly 3 disposed on the printed circuit board 2, and a reflection member 4 arranged on a predetermined surface, from which light emits, of the printed circuit board 2, whereby the reflection member 4 reflects the light to the backlight module. The printed circuit board 2 is a dark-colored plate, such as a blackish green plate. The lighting assembly 3 includes a plurality of LEDs 30 and resistors 31 arranged on the printed circuit board 2 in an alternate relationship and two electrical wires 32 respectively electrically connecting two opposing ends of the printed circuit board 2. The reflection member 4 is a white or another light-colored, rectangular shaped sheet to provide good reflection and has a plurality of recesses 40 formed therein and respectively corresponding to the LEDs 30.

[0020]Referring to FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com