Method and apparatus for controlling an elevator installation with zoning and an interchange floor

a technology of elevator installation and floor, which is applied in the direction of computer control, instruments, etc., can solve the problems of inability to open doors, and inability to solve space problems on the interchange floor, so as to reduce the round-trip time of the elevator and the travel time of passengers. , the effect of inexpensive utilization of the elevator installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

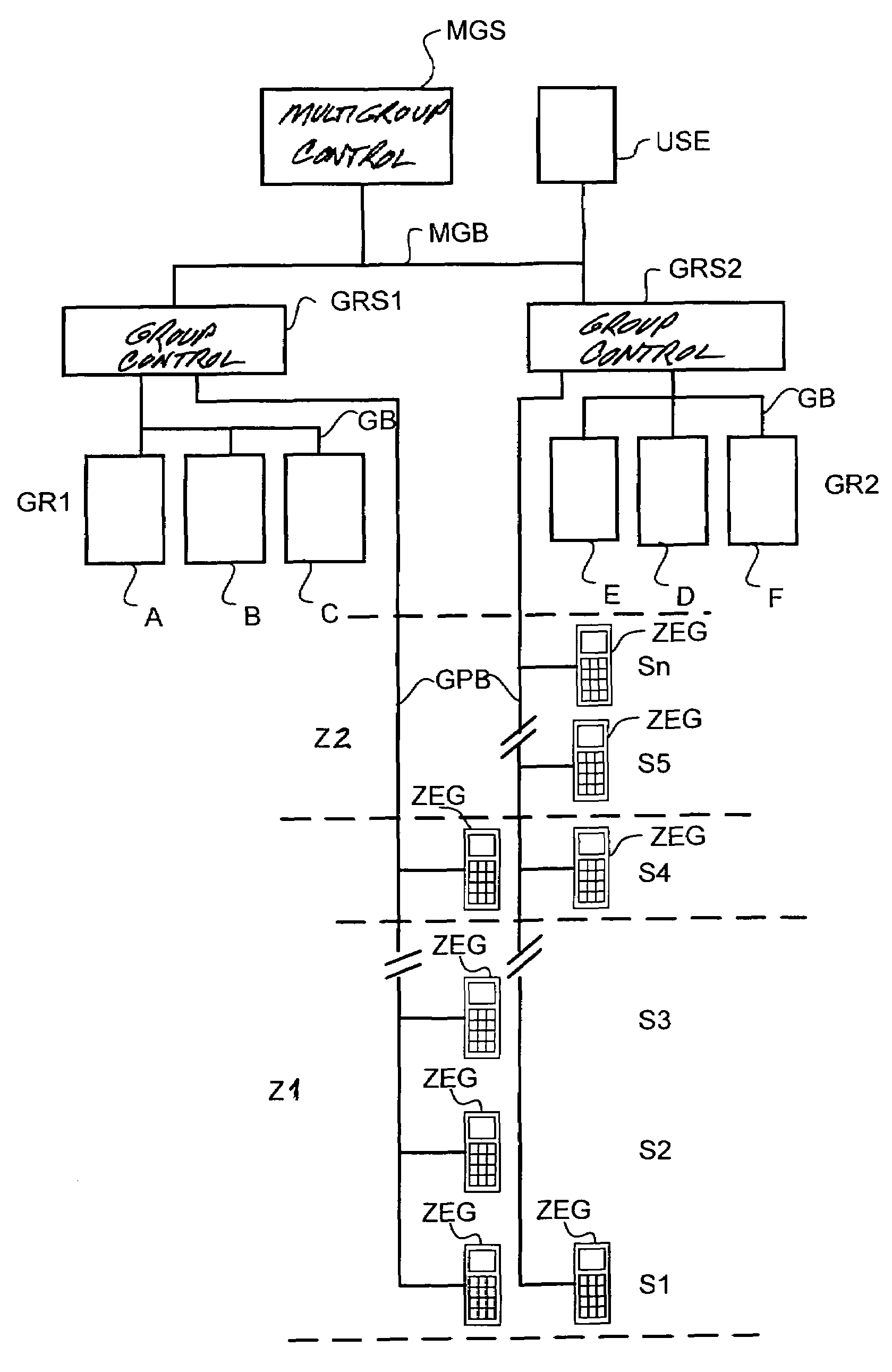

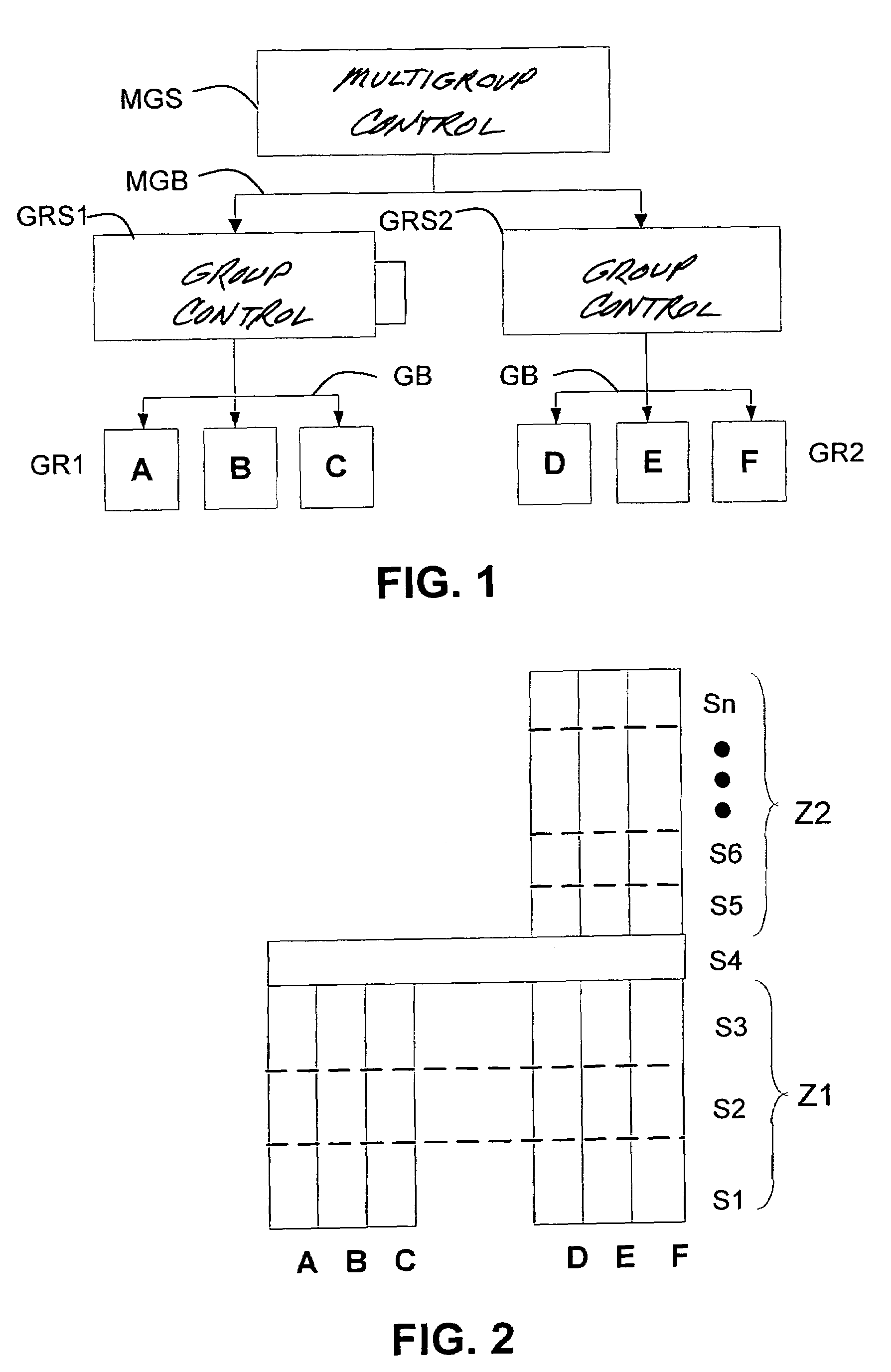

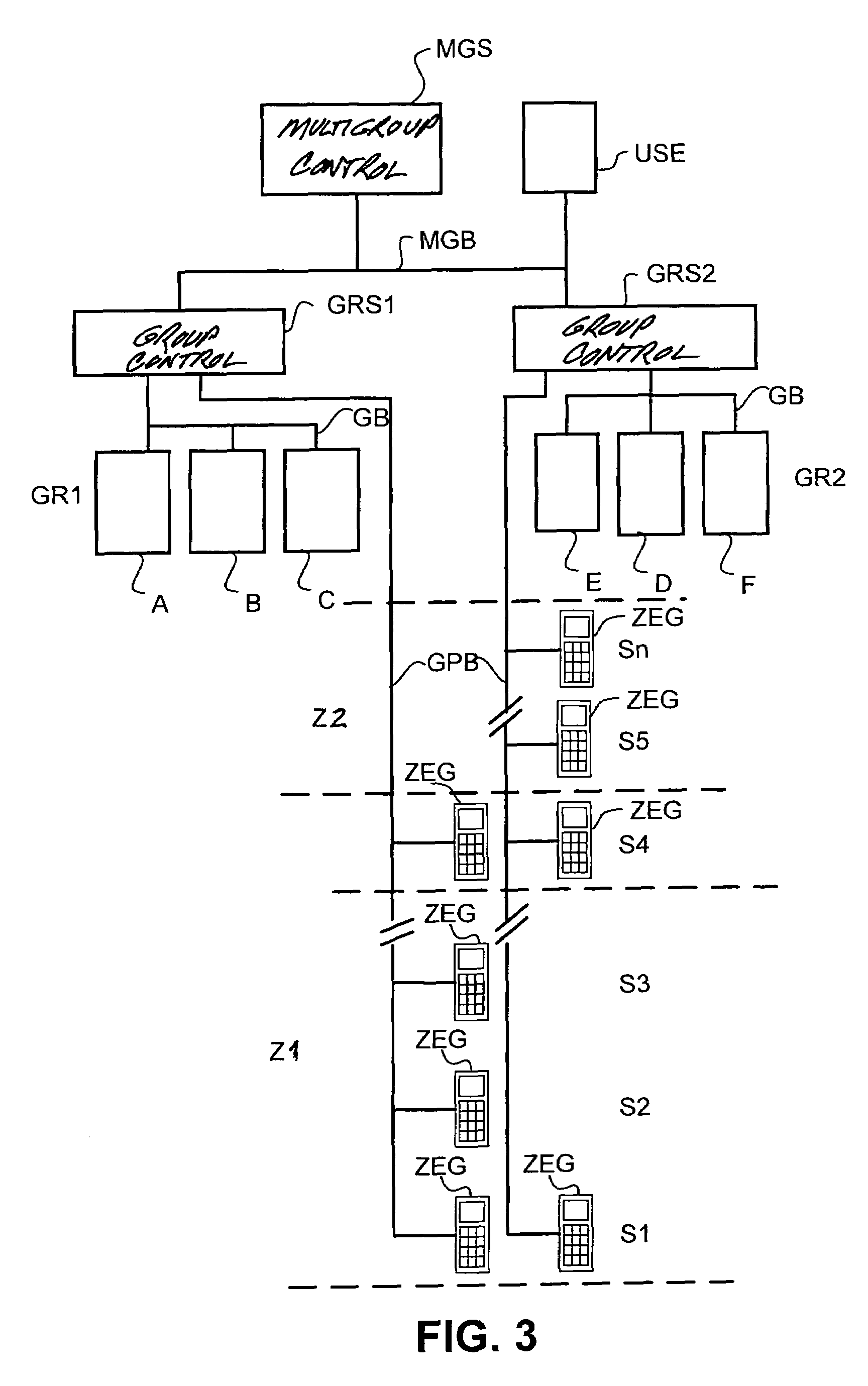

[0026]In FIG. 1 a diagrammatic structure of an elevator installation is represented in schematic form. Especially shown is the combination of two elevator groups into a multigroup with a multigroup control. The individual elevators are designated with the letters A through F, the elevators A to C being combined into a feeder-elevator group GR1 which travels to a first, or lower in a vertical direction, zone Z1 (FIG. 2) of a building. As shown in FIG. 2, floors S1 through S3 of the first zone Z1 are located below an interchange floor S4. The elevators D to F form a connecting-elevator group GR2 and travel as well as to the interchange floor S4 also to the second zone Z2 above the interchange floor S4. A superordinated multigroup control MGS is arranged centrally in a separate computer or in one or in all of group controls GRS1, GRS2. The multigroup control MGS is connected via a multigroup bus MGB with the group controls GRS1 and GRS2. The group controls GRS1 and GRS2 are connected v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com