Thread forming tap with a non-circular cross-section and radially extending cutting edges

a technology of cutting edge and cross-section, which is applied in the direction of manufacturing tools, wood boring tools, transportation and packaging, etc., can solve the problem of disadvantageous tap types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

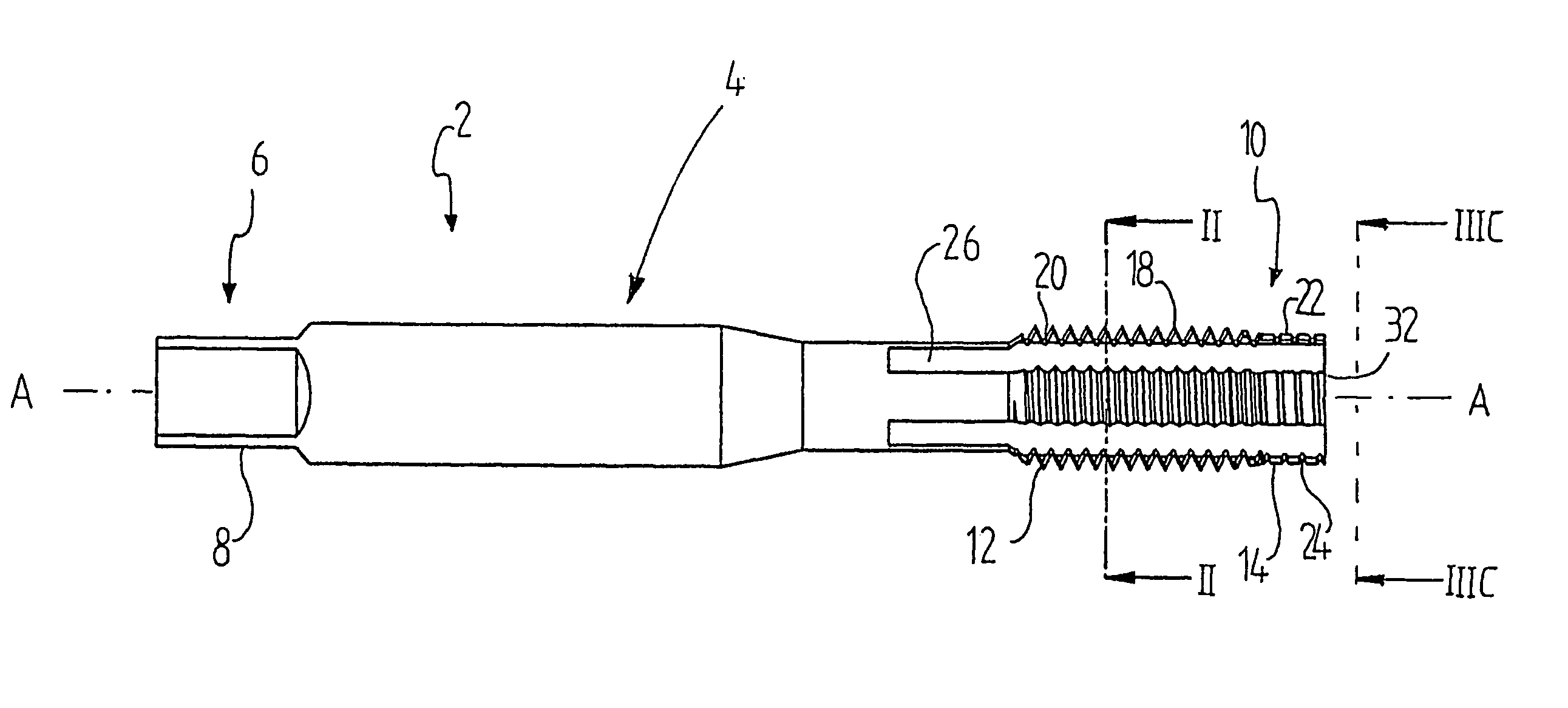

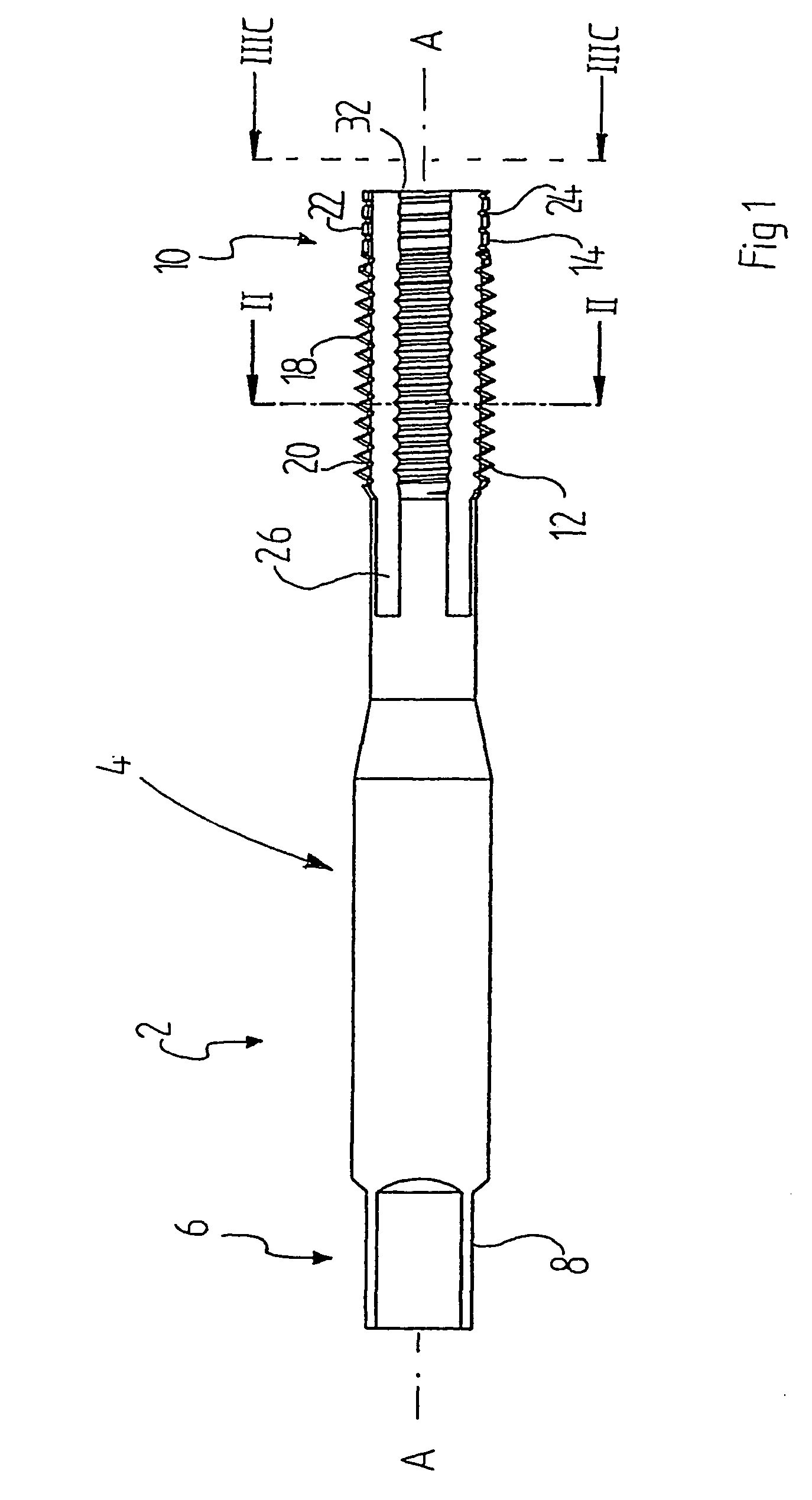

[0019]FIG. 1 shows a thread forming tap 2, comprising an elongated body 4 having an axis A—A. The elongated body 4 has at a first end 6, a connector portion 8 and at a second end 10 a thread forming portion 12, and a thread relief portion 14. The tap 2 is preferably made of a high speed steel or a solid carbide material. The connector portion 8 is adapted to be connected to a tool holder of a drilling or milling machine.

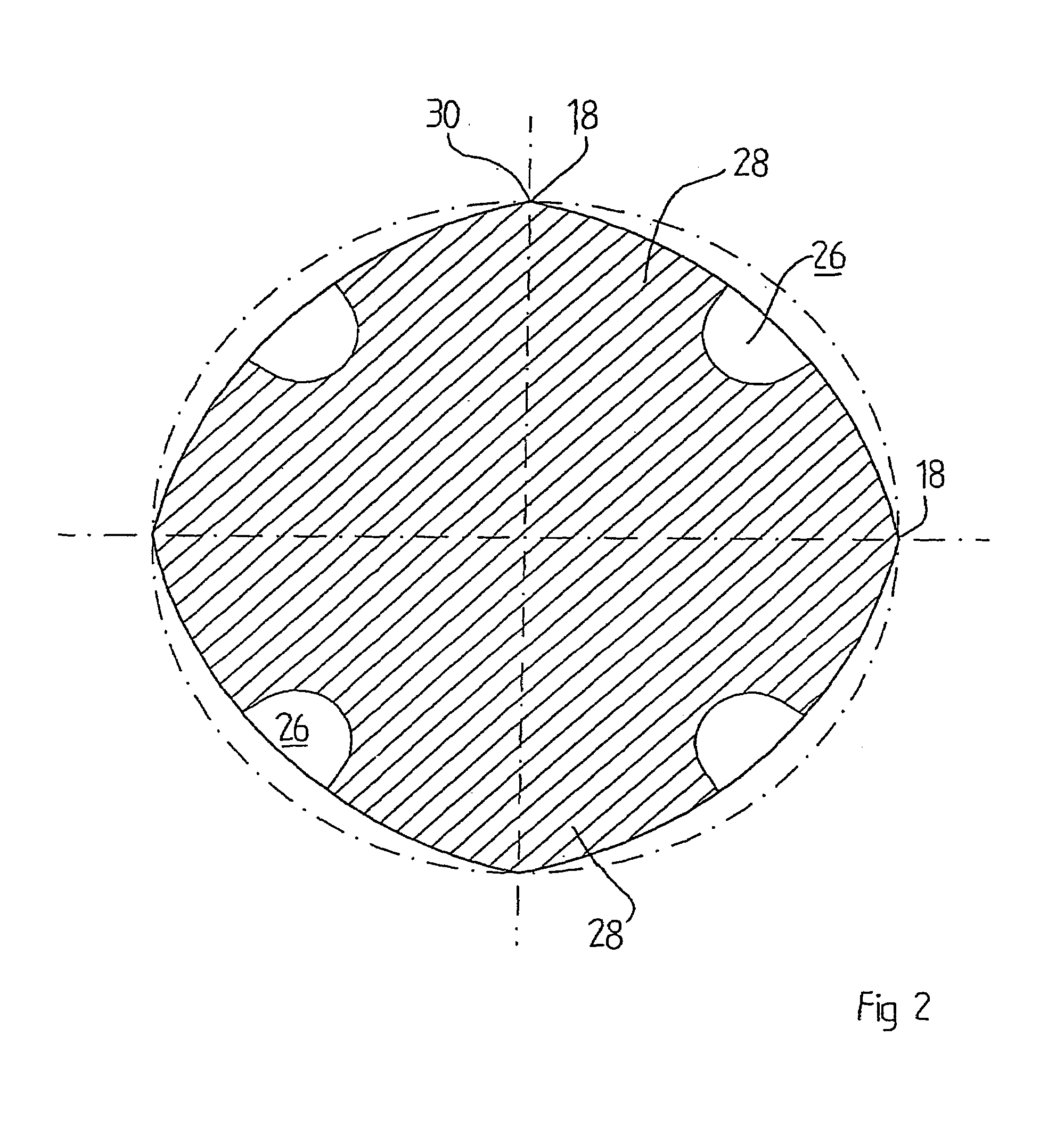

[0020]The thread forming portion has a thread forming thread comprising a ridge 18 separated by a helical groove 20. The diameter of the thread 18 increases from the relief portion 14 towards the second end S and after a few pitches, the diameter is constant (however not circular, see below).

[0021]The thread relief portion 14 is provided with a helical thread having a cut (truncated) ridge 22 having a substantially circular cylindrical form separated by a helical groove 24. The cut ridge 22 has a smaller diameter than the largest diameter of the thread forming thread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com