Methods of and apparatus for casing a borehole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

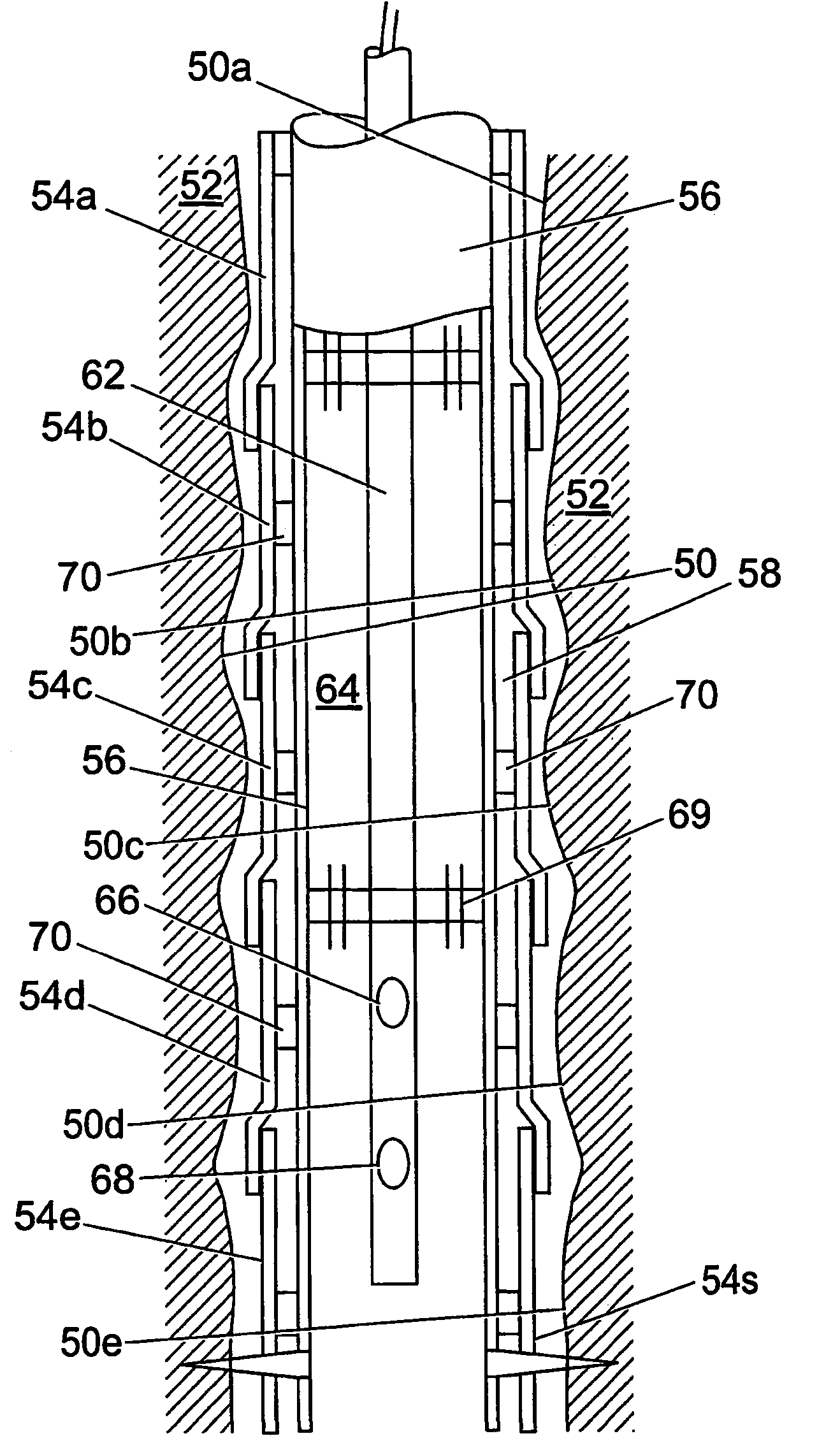

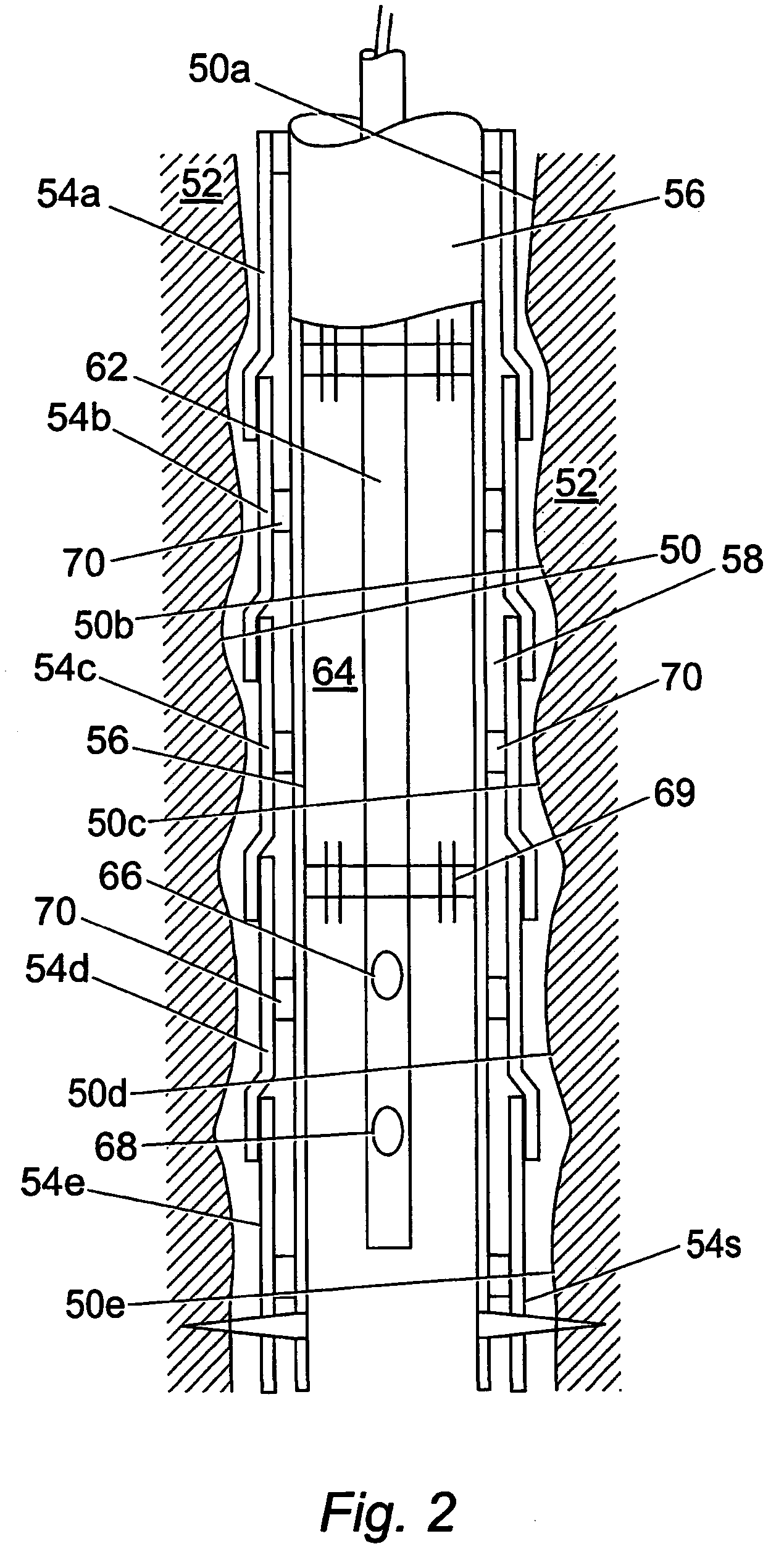

[0055]Referring to the drawings, FIG. 2 shows a particular embodiment of apparatus for casing a borehole 50 that has been drilled into a formation 52 as is known in the art. The borehole 50 generally facilitates the recovery of hydrocarbons (or other fluids) from a reservoir or pay zone (not shown in FIG. 2).

[0056]Like conventional methods for drilling boreholes, borehole 50 is made up of a number of individually drilled portions of borehole, illustrated in FIG. 2 as boreholes 50a to 50e. It will be appreciated that FIG. 2 is not to scale and shows only a portion of the overall borehole 50 and the apparatus, and the number of individual portions of borehole 50a to 50e that are required will vary depending upon the length or depth of the overall borehole 50.

[0057]However, unlike conventional methods, the overall borehole 50 is drilled at a single diameter along its entire length or depth. This is achieved by drilling subsequent portions of borehole 50b to 50e through the first portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com