Simple partial discharge detector for power equipment using acoustic emission technique

a technology of acoustic emission and a detector, which is applied in the direction of instruments, measuring devices, testing dielectric strength, etc., can solve the problems of power failure and disruption of plants, high cost of computer treatment at the post-end of couple capacitors, and even higher cost of computer treatment at the post-end, so as to reduce the load of the cpu in the host. , the effect of costing much less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further illustrated with the preferred embodiments and the related drawings.

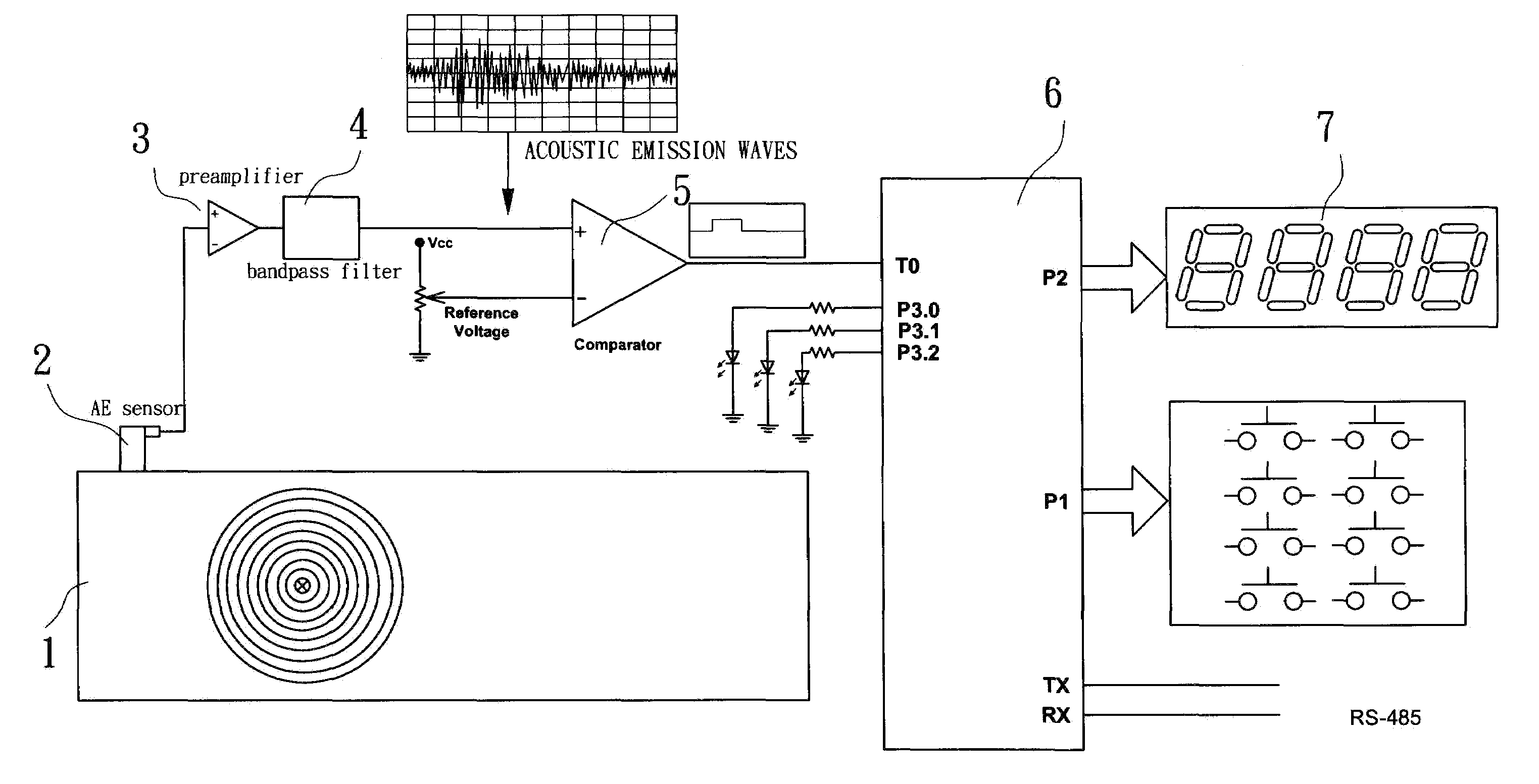

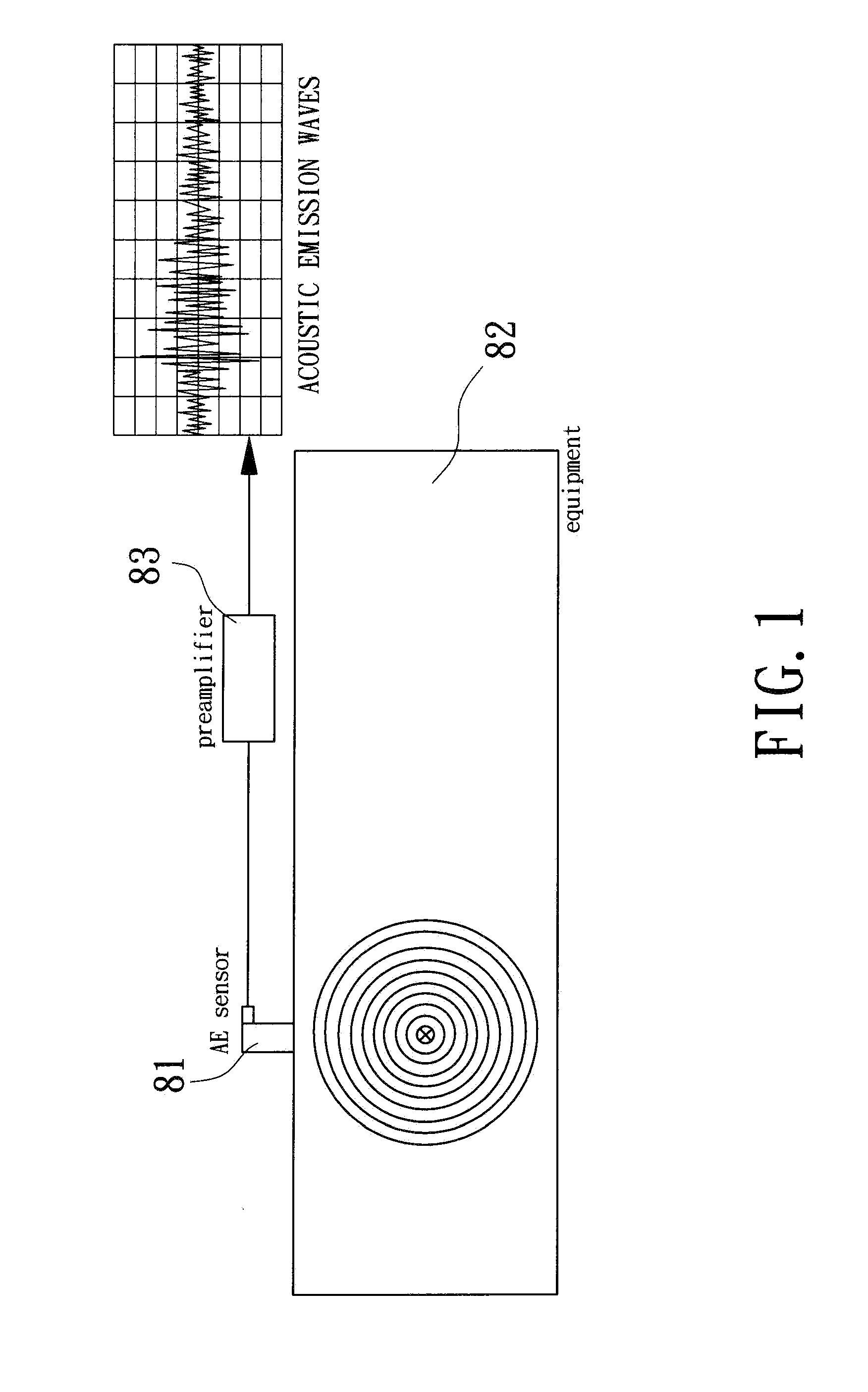

[0027]Please refer to FIG. 3, which shows a simple detector for partial discharge with an acoustic emission technique in accordance with the present invention. On a power equipment (1), an acoustic emission sensor (2) is set to capture acoustic emission signals generated by the power equipment (1). A preamplifier (3) is connected to an output of the acoustic emission sensor (2) to amplify the acoustic emission signal. A bandpass filter (4) is connected to the preamplifier (3) to filter the acoustic emission signals having high and low frequencies. A comparator (5) is set on the output of the bandpass filter (4) to transform the acoustic emission signals having proper frequencies into square-wave signals which are then transmitted to a microprocessor (6). The microprocessor (6) comprises a counter inside to count times for partial discharge by second. An output of the count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com