Method for determining a matrix of transmission cross coefficients in an optical proximity correction of mask layouts

a transmission cross coefficient and mask layout technology, applied in the field of determining the transmission cross coefficient matrix in the optical proximity correction of mask layout, can solve the problems of reducing the achievable resolution limit of the mask structure, inaccurate corrections of this type, distortion of the imaged mask layout on the semiconductor substrate wafer, etc., and achieves the effect of fast and efficient establishmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

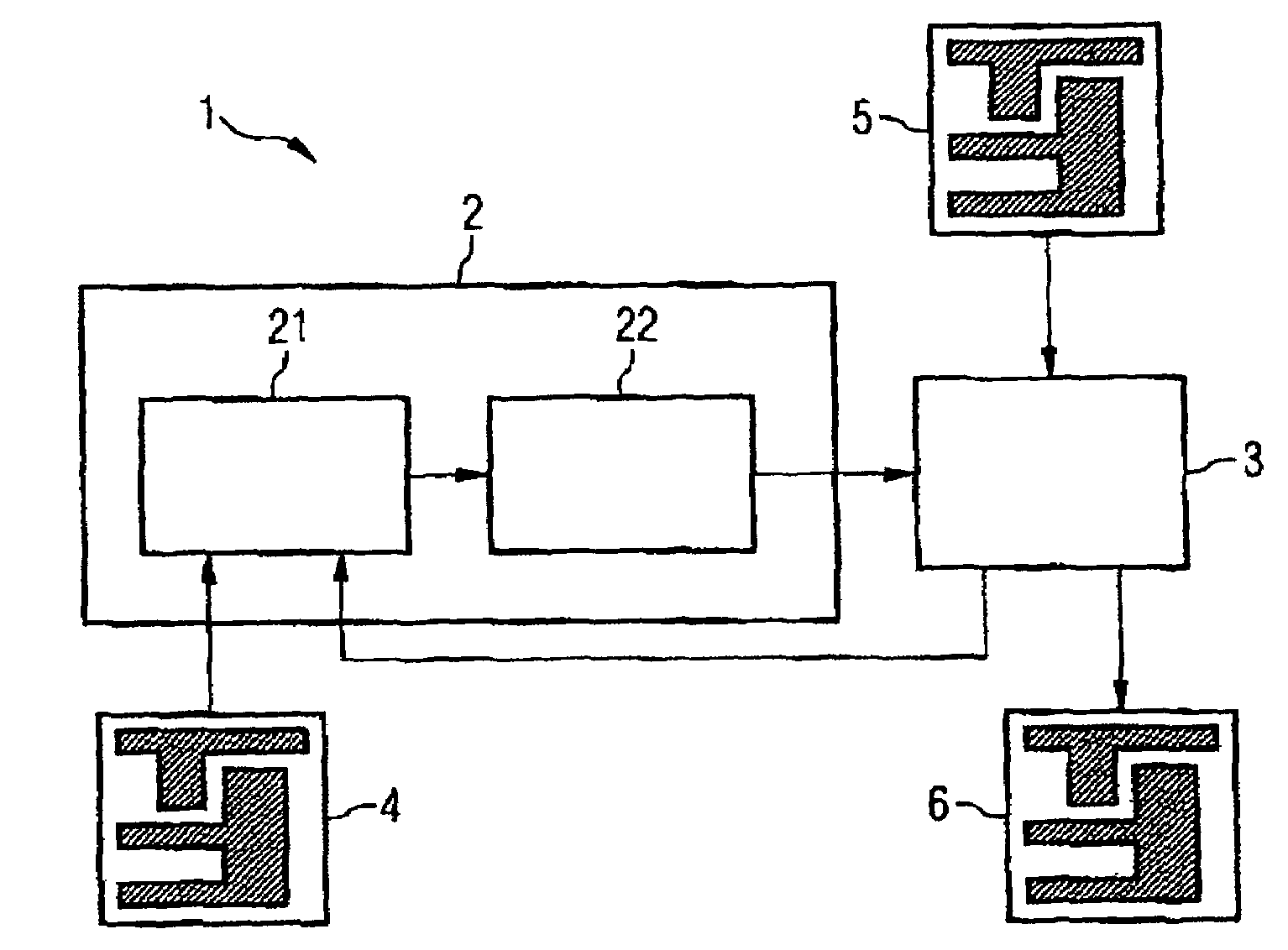

[0028]FIG. 1 shows a block diagram of a typical correction run 1 of a model-based optical proximity correction for a mask structure of an original mask layout 4 of a lithography mask. With the aid of the correction run 1 carried out on a computer, corrections are made to the mask layout 4, which largely compensate for distortions of the image of the mask layout 4 on a semiconductor substrate wafer that occur during a lithography process.

[0029]For this purpose, firstly a simulation of the image of the mask structure of the original mask layout 4 is carried out with the aid of a simulation unit 2. The simulation unit 2 has an optical model 21 and also a resist model 22.

[0030]The optical model 21 is used to register illumination settings of the radiation source used for a lithography process, for example the geometry of an illumination diaphragm and an illumination angle, and also imaging properties of a lens or a lens system used for imaging the mask layout 4 onto a photoresist layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmission cross coefficients | aaaaa | aaaaa |

| optical model | aaaaa | aaaaa |

| displacement frequencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com