Heat-dissipating casing structure

a casing and heat-dissipating technology, applied in the direction of cooling/ventilation/heating modification, basic electric elements, semiconductor devices, etc., can solve the problems of inability to replace the heat pipe of the heat-conductive block, difficult assembly process, etc., to achieve easy and rapid replacement, increase heat-dissipation efficiency, and increase the effect of heat-dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

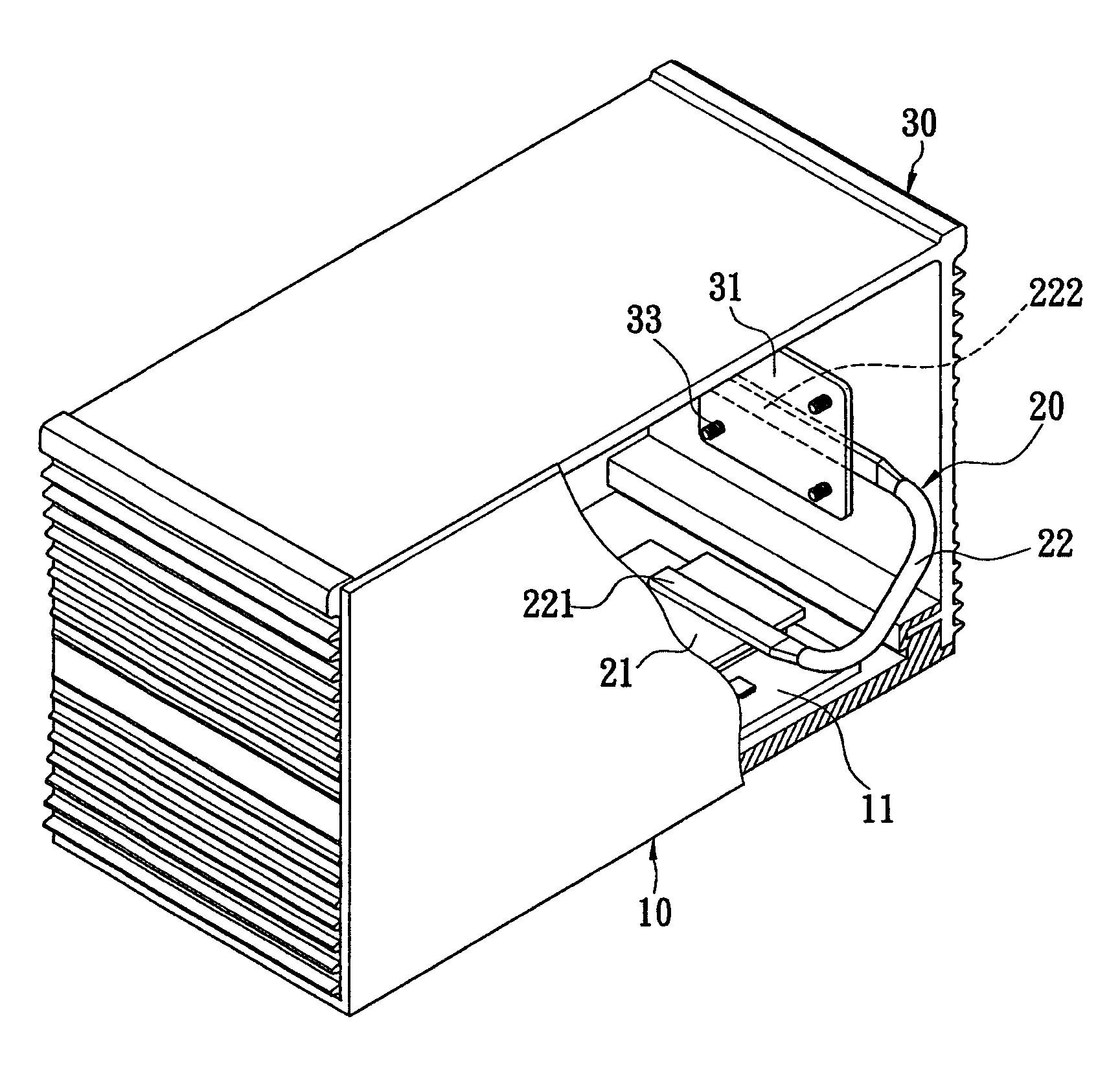

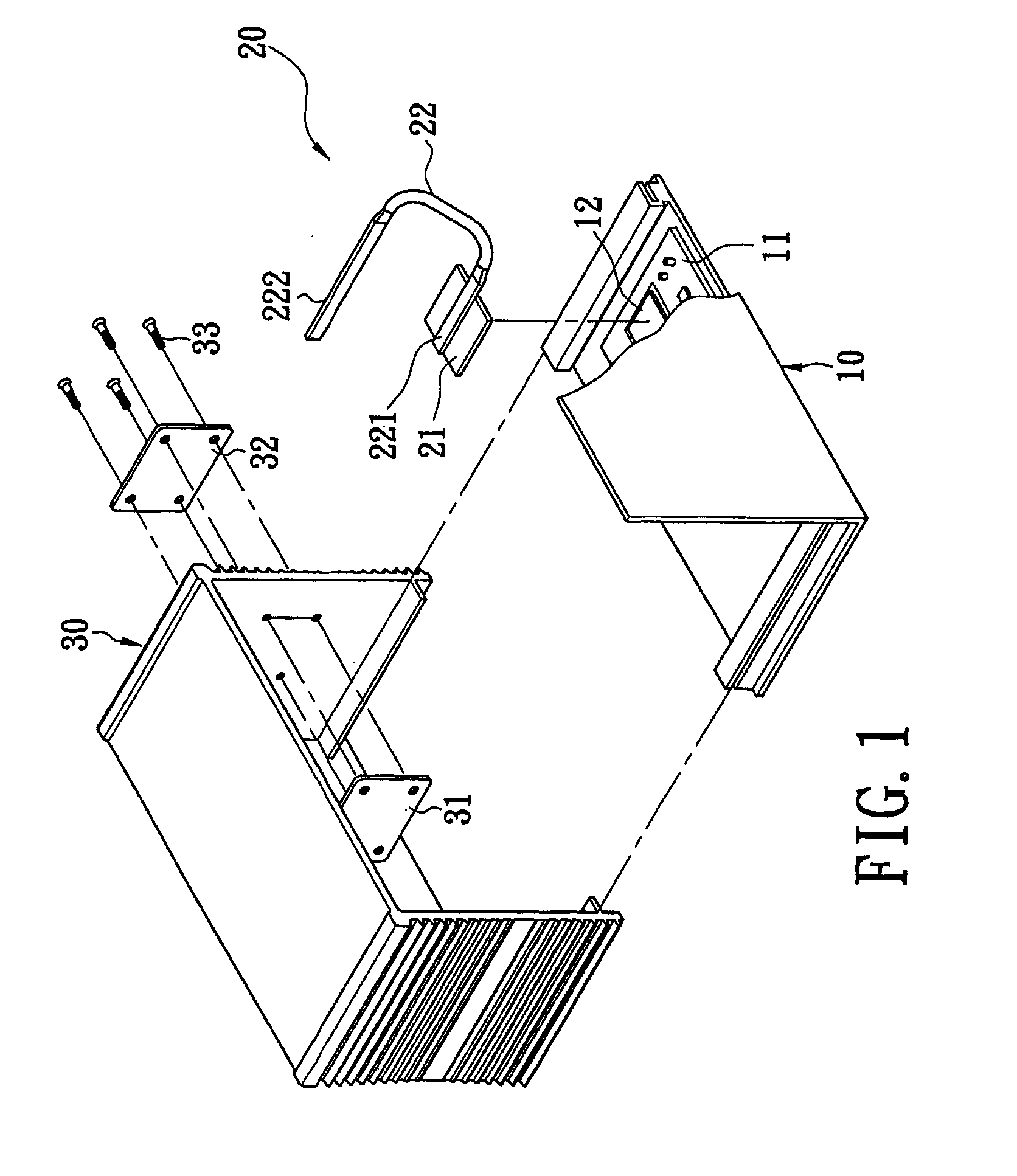

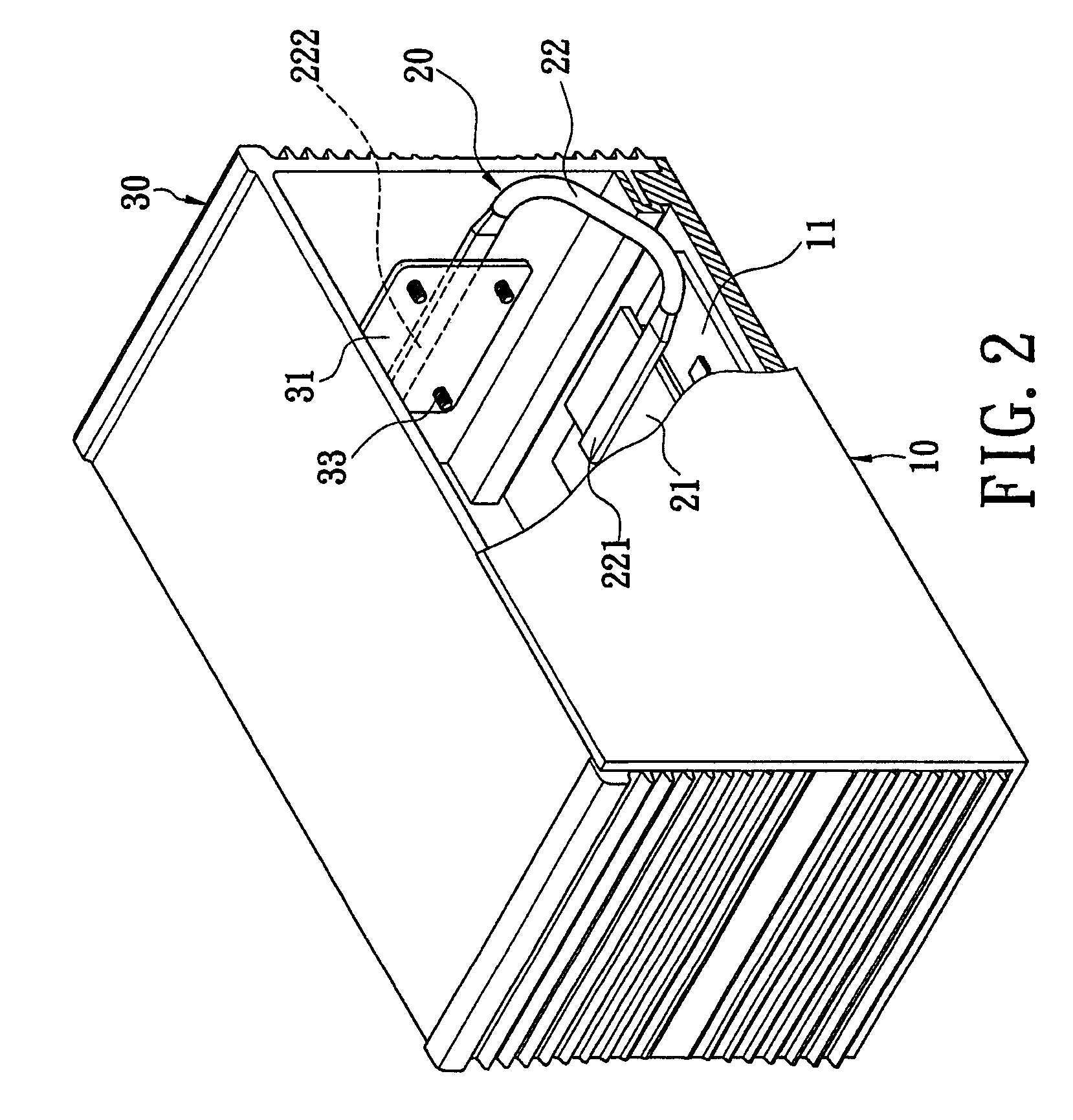

[0026]Referring to FIGS. 1 to 3, the present invention provides a heat-dissipating casing structure. The heat-dissipating casing structure comprises a base seat 10, a heat-dissipating module 20, and a casing 30. The base seat 10 has a PCB (Printed Circuit Board) 11 disposed thereon. The PCB 11 has a heat-generating element 12 such as CPU.

[0027]The heat-dissipating module 20 has a first heat-conducting block 21 and a first heat pipe 22. The heat-dissipating module 20 is screwed on the base seat 10 or is disposed on the base seat 10 by any fixing method. The first heat-conducting block 21 is made of heat-conducting metal material. The first heat-conducting block 21 is disposed on the heat-generating element 12 for absorbing heat from the heat-generating element 12.

[0028]In this embodiment, the first heat pipe 22 is bent in a U shape and has a first side 221 of a second side 222. The first side 221 connects with the first heat-conducting block 21. The second side 222 is bent upward fro...

fourth embodiment

[0038]FIGS. 8 to 10 show the present invention. A hard disk 40 is assembled on the base seat 10. A hard disk support 41 is covered on the hard disk 40. The PCB 11 is disposed on the hard disk support 41 and has a heat-generating element 12 (as shown in FIG. 9). The heat-dissipating casing structure further comprises a second heat pipe 14 that includes a first side 141 and a second side 142. The first side 141 connects to the hard disk support 41. The second side 142 extends from one end of the first side 141 to a lateral side of the base seat 10. The heat-dissipating module 20 has a first heat-conducting block 21 and a first heat pipe 22. The heat-dissipating module 20 is disposed on the base seat 10. The first heat-conducting block 21 has a vertical type heat sink 211 disposed thereon. The first heat-conducting block 21 is attached to the heat-generating element 12.

[0039]The first side 221 of the first heat pipe 22 connects with the first heat-conducting block 21. The second side 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com